Installation

14

CLCH-SVN05C-EN

a small air leak between the duct and the deck will destroy

most of the attenuation available from the steel decking.

In addition, special consideration may be required to

ensure that the weight of the unit does not crush the roof

deck at those points where the deck is between the curb

and support joist. Poured insulation will usually add the

required strength, while the use of rigid insulation may

require placement of three-inch support channels on the

decking.

As a general rule, exhaust fan noise is not a problem and

can be adequately attenuated by the return ductwork. For

critical applications where return ductwork is not required,

however, installation of an acoustically-lined “return T” is

recommended; see

Figure 21

.

Supply and Return Air Ductwork

Ductwork for all units must be fabricated and installed by

the installing contractor; to ensure proper duct

construction and installation, SMACNA recommendations

should be closely followed.

Below are several typically used guidelines for ductwork

construction:

•

Elbows with turning vanes or splitters are

recommended to minimize air noise and resistance.

•

The first elbow in the ductwork leaving the unit should

be no closer than 3 fan diameters from the unit,

thereby minimizing noise and resistance.

In those instances where the unit is installed over an

acoustically critical area, additional treatment of the

ductwork is recommended. Both supply and return

ductwork should be lined internally with glass fiber duct

liner 1-inch thick. The external surface of the supply duct

should be covered with an acoustical barrier material such

as one or two pound/sq. ft. sheet lead (1/64-inch or 1/32-

inch) or loaded vinyl sheet or gypsum board for the first 10

ft. of ductwork. The lining should extend from the point

where the duct penetrates the roof to a distance of 10 ft.

beyond the vertical drop from the unit.

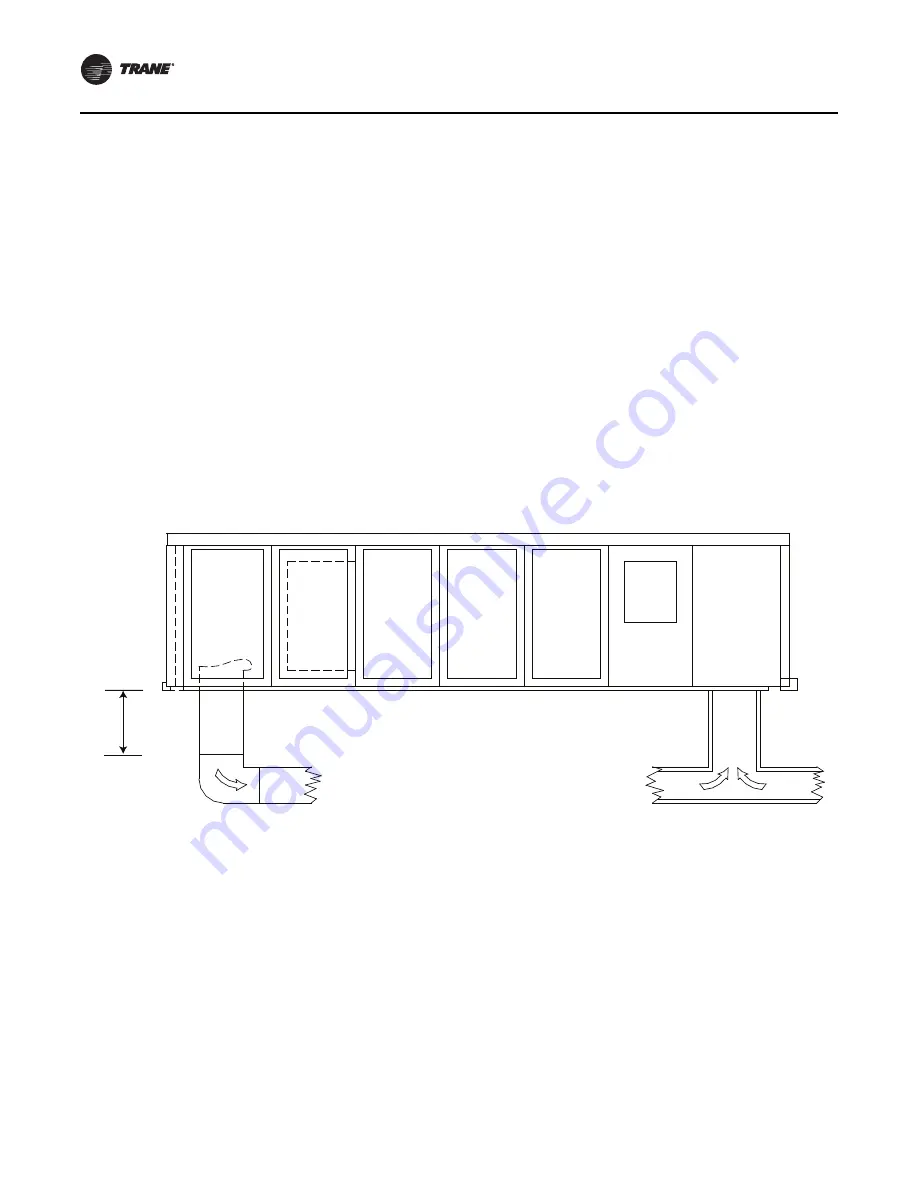

Figure 21.

Typical supply and return ductwork

Coil

space

Vertical

discharge

3 fan

diameters

Return

air

Use lined duct for all returns (1-inch thick, 6-pound density fiberglass recommended).