Removal and Installation

COM-SVN01D-EN

17

CSHN/CSHL

•

Before removing wires

, mark them so that they can be

put back on the same terminal when the new

compressor is installed.

•

Insure that the compressor model terminals are

installed on the correct terminals (see

•

If the compressor is not wired properly, it will shut off

within five seconds.

•

Proper torque for the terminal set screws and nuts is 30

in-lb.

•

Before starting the compressor

, check the electrical

phasing with a phase sequence meter similar to an

Ideal-Sperry Model 61-520.

Figure 11.

CSHN/CSHL wiring diagram

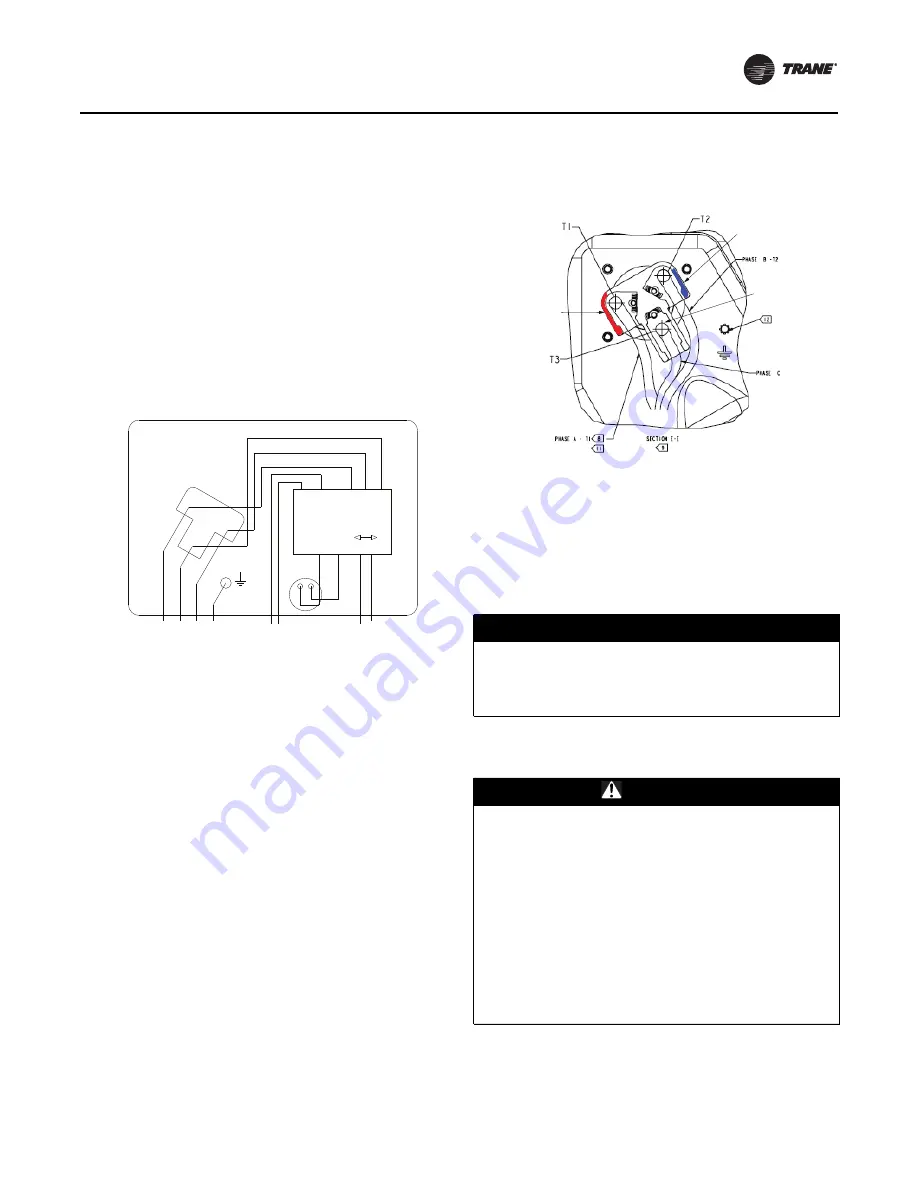

CSHD

The terminal blocks have red and blue marks for phase

identification. Compressor terminal T1 is red, compressor

terminal T2 is blue, and compressor terminal T3 is

unmarked. Depending on the unit type, several methods

of marking the wires may be used, colored wires, wire

color marks on the wire or wire numbers to indicated the

proper location of the wire on the compressor terminal

block.

If the wires are not marked, ensure that you mark them

prior to removing them so that they can be reinstalled in

the same position.

Figure 12.

CSHD wiring diagram

•

Ensure that the compressor model terminals are

installed on the correct terminals (see

•

Proper torque for the terminal screws is 25 in·lb.

•

Before starting the compressor, check the electrical

phasing with a phase sequence meter similar to an

Ideal-Sperry Model 61-520.

NOTICE

Improper Power Phasing!

Check phasing before starting compressor. Operating

the compressor with improper phasing could cause

compressor failure.

Leak Detection

WARNING

Explosion Hazard!

Failure to follow these instructions could result in death

or serious injury or equipment or property-only

damage.

Use only dry nitrogen with a pressure regulator for

pressurizing unit. Do not use acetylene, oxygen or

compressed air or mixtures containing them for

pressure testing. Do not use mixtures of a hydrogen

containing refrigerant and air above atmospheric

pressure for pressure testing as they may become

flammable and could result in an explosion. Refrigerant,

when used as a trace gas should only be mixed with dry

nitrogen for pressurizing units.

PHASING TO BE CONNECTED AS SHOWN TO

PREVENT REVERSE ROTATION

MODULE INPUT

VOLTAGE

POWER

SUPPLY

CONTROL

CIRCUIT

L1

L3

L2

BLACK

BLUE

RED

L1

L3

L2

A

B

C

L1

L3

L2

M1

NO

M2

COM

CONTROL

VOLTAGE

TH-

S1

TH+

S2

N

L

Blue mark

indicating T2

(Phase B)

Red mark

indicating T1

(Phase A)

Unmarked

T3

(Phase C)