102

CVHH-SVX001G-EN

Remaining carbon capacity% =

100 - (pump-out minutes since last regen/pump-out

minutes at 100% capacity)*100

For example, an R-1233zd-equipped chiller that has

accumulated 80 minutes of purge pump-out time since

the last carbon tank regeneration would be estimated

to have 84 percent carbon tank capacity remaining:

100 – (80/500)*100 = 84%

The purge controls may initiate a carbon tank

regeneration cycle when the remaining carbon tank

capacity is calculated to be less than 80 percent.

However, the continued stable operation of the chiller

is always more important than the regeneration of the

carbon tank. Therefore, the following rules apply:

1. If the Daily Pump-out Limit is disabled, a

regeneration cycle may not be initiated, regardless

of the value of the remaining carbon capacity.

Also, if the Daily Pump-out Limit is disabled during

a regeneration cycle, the regeneration cycle must

be terminated.

2. When the remaining carbon capacity is less than

80 percent, a regeneration cycle will be initiated at

the next opportunity when the chiller is running

(after the chiller has started and no pump-out

minutes have accumulated for the previous

60 minutes).

3. If there is no opportunity to purge as indicated by

Rules 1 and 2 and the remaining carbon capacity is

less than 50 percent, a regeneration cycle will be

initiated at the best opportunity when the chiller is

shut down (and no pump-out minutes have

accumulated for the previous 60 minutes).

4. If there is no opportunity to regenerate as indicated

by Rules 1, 2, and 3 and the carbon capacity drops

below 0 percent, then a regeneration cycle is

initiated.

5. Note that, if at any time during the regeneration

cycle the chiller is running and shuts down or if the

chiller is off and starts up, then the regeneration

cycle is continued.

Carbon Tank Regeneration Sequence

W

WA

AR

RN

NIIN

NG

G

H

Ha

azza

arrd

do

ou

uss V

Vo

olltta

ag

ge

e!!

F

Fa

aiillu

urre

e tto

o d

diisscco

on

nn

ne

ecctt p

po

ow

we

err b

be

effo

orre

e sse

errv

viicciin

ng

g cco

ou

ulld

d

rre

essu

ulltt iin

n d

de

ea

atth

h o

orr sse

erriio

ou

uss iin

njju

urry

y..

D

Diisscco

on

nn

ne

ecctt a

allll e

elle

eccttrriicc p

po

ow

we

err,, iin

nccllu

ud

diin

ng

g rre

em

mo

otte

e

d

diisscco

on

nn

ne

eccttss b

be

effo

orre

e sse

errv

viicciin

ng

g.. F

Fo

ollllo

ow

w p

prro

op

pe

err

llo

occkko

ou

utt//tta

ag

go

ou

utt p

prro

occe

ed

du

urre

ess tto

o e

en

nssu

urre

e tth

he

e p

po

ow

we

err

cca

an

n n

no

ott b

be

e iin

na

ad

dv

ve

errtte

en

nttlly

y e

en

ne

errg

giizze

ed

d.. V

Ve

erriiffy

y tth

ha

att n

no

o

p

po

ow

we

err iiss p

prre

esse

en

ntt w

wiitth

h a

a v

vo

ollttm

me

ette

err..

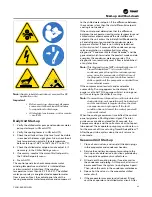

X39003892001A

N

No

otte

e:: Graphic labels (shown above) are used for CE

application only.

IIm

mp

po

orrtta

an

ntt::

•

Before servicing, disconnect all power

sources and allow at least 30 minutes

for capacitors to discharge.

•

All electrical enclosures—unit or remote

—are IP2X.

If the purge controller determine that carbon tank

regeneration is desired and is allowed, the purge

controls:

1. Disable the purge refrigeration circuit and the

pump-out solenoid valve.

2. Open the regeneration solenoid valve and turn on

the carbon tank heater.

3. Monitor the carbon temperature until it reaches the

regeneration temperature value of 240°F (115.6°C),

and control within a ±10°F (5.6°C) dead band for

15 minutes (this step should take approximately

three hours).

•

If the carbon tank temperature does not increase

more than 25°F (13.9°C) in the first two hours,

the controller generates a non-latching

diagnostic, Carbon Regeneration Temperature

Too Low, and indicates a status of Carbon

Regeneration Disabled. The purpose of this

diagnostic is to identify a failed heater or

temperature sensor. It prevents automatic

regeneration from occurring, but a service

technician can initiate a manual regeneration for

Summary of Contents for CVHH CenTraVac

Page 126: ...126 CVHH SVX001G EN N No ot te es s ...