CVHH-SVX001G-EN

13

and storage of oil, oil filters, refrigerant filters, and filter

dryer cores.

Installation Requirements and

Contractor Responsibilities

A list of the contractor responsibilities typically

associated with the unit installation process is

provided.

W

WA

AR

RN

NIIN

NG

G

C

Co

om

mb

bu

ussttiib

blle

e M

Ma

atte

erriia

all!!

F

Fa

aiillu

urre

e tto

o ffo

ollllo

ow

w iin

nssttrru

uccttiio

on

nss b

be

ello

ow

w cco

ou

ulld

d rre

essu

ulltt iin

n

d

de

ea

atth

h o

orr sse

erriio

ou

uss iin

njju

urry

y o

orr e

eq

qu

uiip

pm

me

en

ntt d

da

am

ma

ag

ge

e..

S

Sh

hrriin

nkk--w

wrra

ap

p iiss a

a cco

om

mb

bu

ussttiib

blle

e m

ma

atte

erriia

all.. A

Av

vo

oiid

d o

op

pe

en

n

fflla

am

me

ess a

an

nd

d h

ho

ott ssp

pa

arrkkss..

N

No

otte

e:: The chiller should remain within its protective

shrink-wrap covering during storage.

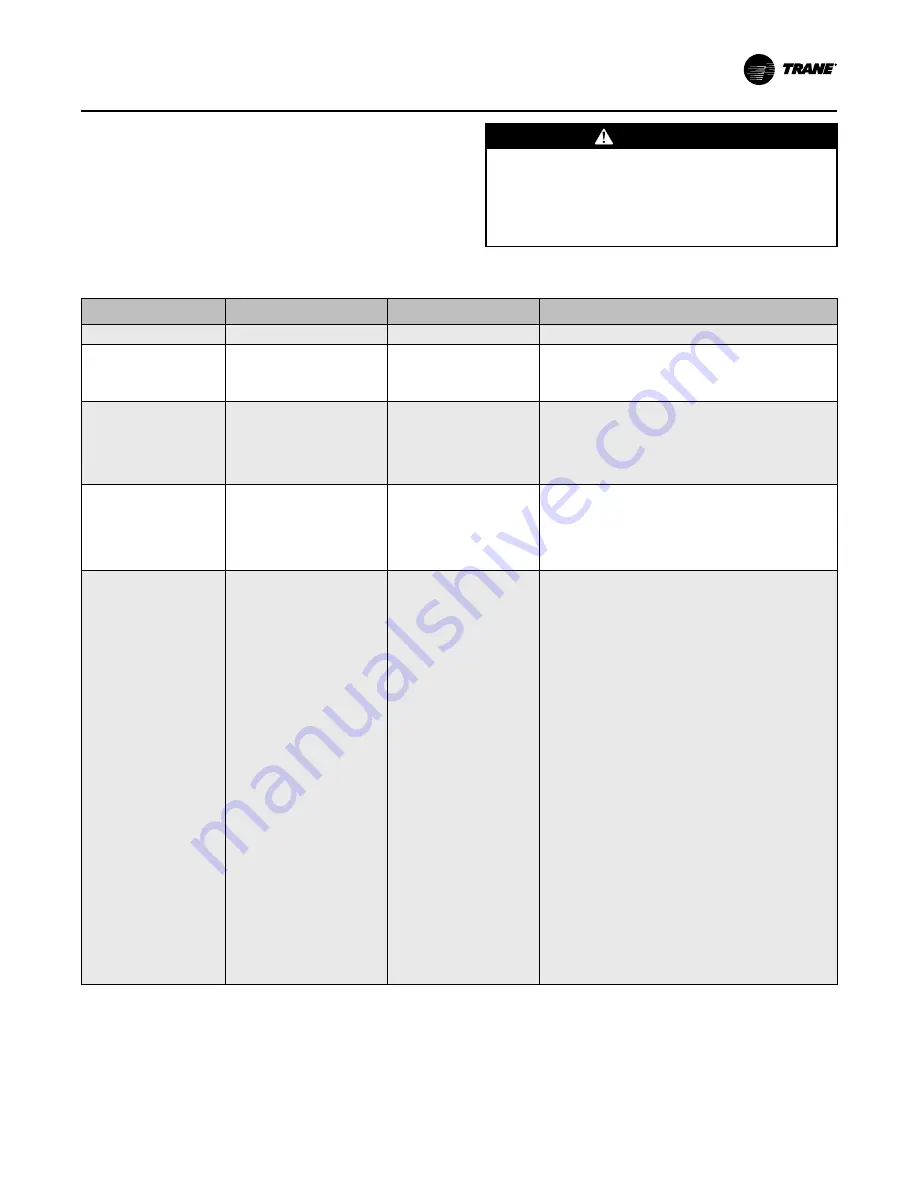

Type of Requirement

Trane Supplied

Trane Installed

Trane Supplied

Field Installed

Field Supplied

Field Installed

Foundation

•

Meet foundation requirements

Rigging

•

Safety chains

•

Clevis connectors

•

Lifting beam

Disassembly/Reassembly

(as required)

•

Trane will perform or have

direct on-site supervision

of the disassembly and

reassembly work (contact

your local Trane office for

pricing)

Isolation

•

Isolation pads or spring

isolators

•

Isolation pads or spring isolators

•

Optional spring isolators, when required, are

installed by others; do NOT overload springs and do

NOT install isolation springs if they block serviceable

parts such as the oil tank system, service valves,

etc.

Electrical

•

Circuit breakers or fusible

disconnects (optional)

•

Unit-mounted starter

(optional)

•

Power factor correction

capacitors (PFCCs)

(optional)

•

Jumper bars

•

Temperature sensor

(optional outdoor air)

•

Flow switches (may be

field supplied); for

installation instructions

for the ifm efector

®

flow

detection controller and

sensor, refer to

Flow Detection

Controller and Sensor—

ifm efector,” p. 29

or

Trane literature that

shipped with the device

•

Remote-mounted

starter (optional)

•

Circuit breakers or fusible disconnects (optional)

•

Electrical connections to unit-mounted starter

(optional)

•

Electrical connections to remote-mounted starter

(optional)

•

Wiring sizes per submittal and National Electric Code

(NEC) or local codes

•

PFCCs (remote mounted starter optional only)

•

Terminal lugs

•

Ground connection(s)

•

Jumper bars

•

BAS wiring (optional)

•

Inter-processor communication (IPC) wiring (AFD

and remote-mounted starters only)

•

Control voltage wiring (AFD and remote-mounted

starters only)

•

Oil pump interlock wiring (AFD and remote mounted

starters only)

•

High condenser pressure interlock wiring (AFD and

remote-mounted starters only)

•

Chilled water pump contactor and wiring including

interlock

•

Condenser water pump contactor and wiring

including interlock

•

Option relays and wiring

Summary of Contents for CVHH CenTraVac

Page 126: ...126 CVHH SVX001G EN N No ot te es s ...