92

CVHH-SVX001G-EN

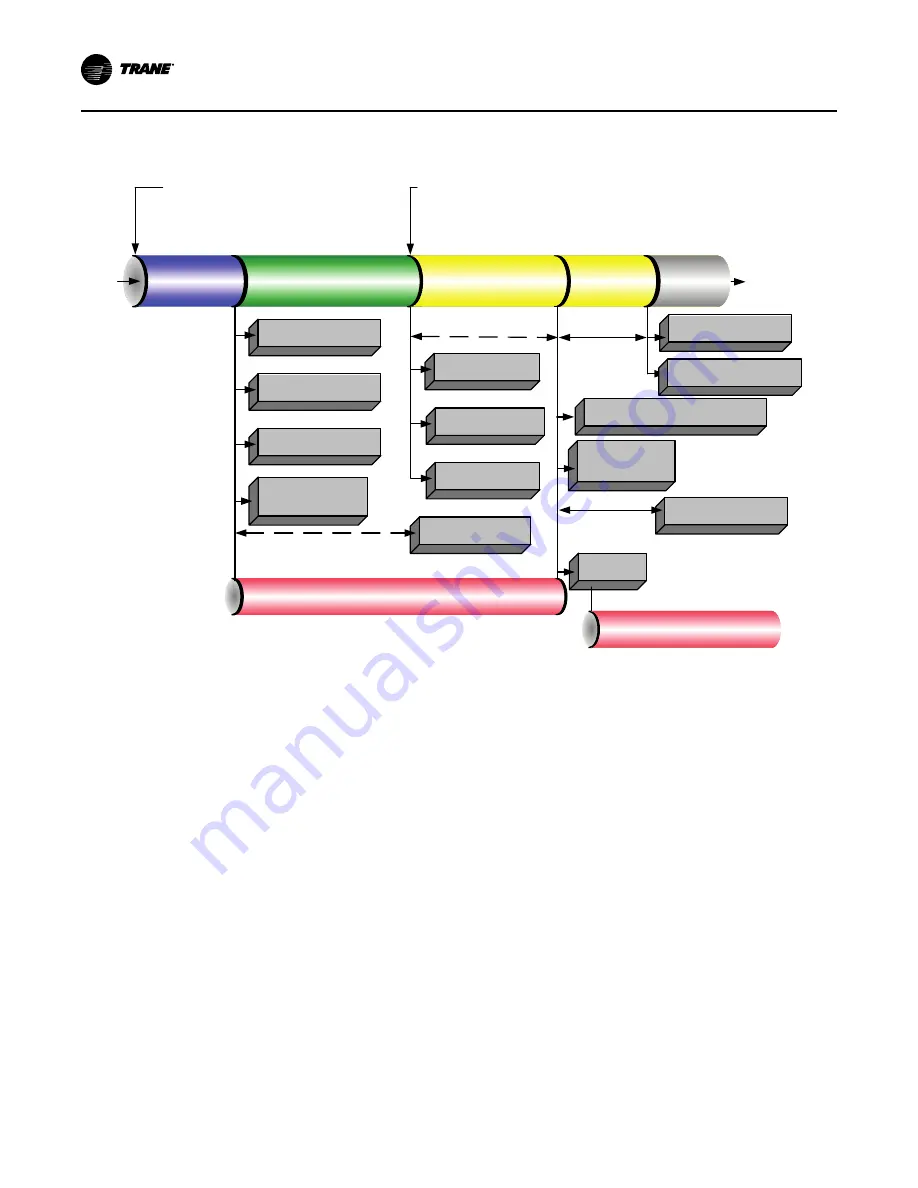

Figure 57.

Sequence of operation: ice building: stopped to ice to ice building complete

Ice Making Command:

1. Front Panel

2. Tracer

3. External Input

Evap Entering

Water Temp Falls

Below the Ice

Termination

Setpoint

Auto

Run Inhibit

(Ice Building

Complete)

Starting

Compressor

Running

(Ice Building)

Preparing to

Shut Down

Shutting

Down

Run

Inhibit

Open IGV at Max Rate/

Max AFD Frequency

Close IGV

(0–50 sec)

Postlube

(3 min)

Heat Relief Request Relay

Delay (1–60 min)

Ignore Evap Pump

Off Delay Time

for Ice Building

Close IGV/Min AFD

Frequency

De-Energize Oil Pump

Open Oil Vent Line Valve

Hold position of Oil Vent Line Valve

De-Energize

Condenser

Water Pump Relay

De-Energize Evaporator

Water Pump Relay

De-Energize

Compressor

Confirm No Compressor Currents

Within 8 sec

Ignore Softloading and

Set CLS=100%

Energize Ice Building

Relay

Begin Oil Vent Line

Valve low limit venting

Enforce All Limits and Running Mode Diagnostics

De-Energize Ice

Building Relay

De-Energize Heat

Relief Request Relay

Energize Head Relief

Request Relay

Free Cooling Cycle

Based on the principle that refrigerant migrates to the

coldest area in the system, the free cooling option

adapts the basic chiller to function as a simple heat

exchanger. However, it does not provide control of the

leaving chilled water temperature.

If condenser water is available at a temperature lower

than the required leaving chilled water temperature,

the operator interface must remain in AUTO and the

operator starts the free cooling cycle by enabling the

Free Cooling mode in the Tracer

®

AdaptiView

™

Feature Settings group of the operator interface, or by

means of a BAS request. The following components

must be factory- or field-installed to equip the unit for

free cooling operation:

•

a refrigerant gas line, and electrically-actuated

shutoff valve, between the evaporator and

condenser, and

•

a valved liquid return line, and electrically-actuated

shutoff valve, between the condenser sump and the

evaporator.

When the chiller is changed over to the free cooling

mode, the compressor will shut down if running and

the shutoff valves in the liquid and gas lines open; unit

control logic prevents the compressor from energizing

during free cooling. Since the temperature and

pressure of the refrigerant in the evaporator are higher

than in the condenser (i.e., because of the difference in

water temperature), the refrigerant in the evaporator

vaporizes and travels to the condenser, cooling tower

water causes the refrigerant to condense on the

condenser tubes, and flow (again, by gravity) back to

the evaporator.

This compulsory refrigerant cycle is sustained as long

as a temperature differential exists between condenser

and evaporator water. The actual cooling capacity

provided by the free cooling cycle is determined by the

difference between these temperatures which, in turn,

determines the rate of refrigerant flow between the

evaporator and condenser shells.

If the system load exceeds the available free cooling

capacity, the operator must manually initiate

changeover to the mechanical cooling mode by

disabling the free cooling mode of operation. The gas

and liquid line valves then close and compressor

operation begins (refer to the figure in

Sequence of Operation—Wye-delta,” p. 87

[power up

to starting], beginning at Auto mode). Refrigerant gas

is drawn out of the evaporator by the compressor,

where it is then compressed and discharged to the

condenser.

Summary of Contents for CVHH CenTraVac

Page 126: ...126 CVHH SVX001G EN N No ot te es s ...