CVHH-SVX001G-EN

105

Recommended Maintenance

W

WA

AR

RN

NIIN

NG

G

H

Ha

azza

arrd

do

ou

uss V

Vo

olltta

ag

ge

e w

w//C

Ca

ap

pa

acciitto

orrss!!

F

Fa

aiillu

urre

e tto

o d

diisscco

on

nn

ne

ecctt p

po

ow

we

err a

an

nd

d d

diisscch

ha

arrg

ge

e

cca

ap

pa

acciitto

orrss b

be

effo

orre

e sse

errv

viicciin

ng

g cco

ou

ulld

d rre

essu

ulltt iin

n d

de

ea

atth

h o

orr

sse

erriio

ou

uss iin

njju

urry

y..

D

Diisscco

on

nn

ne

ecctt a

allll e

elle

eccttrriicc p

po

ow

we

err,, iin

nccllu

ud

diin

ng

g rre

em

mo

otte

e

d

diisscco

on

nn

ne

eccttss a

an

nd

d d

diisscch

ha

arrg

ge

e a

allll m

mo

otto

orr sstta

arrtt//rru

un

n

cca

ap

pa

acciitto

orrss b

be

effo

orre

e sse

errv

viicciin

ng

g.. F

Fo

ollllo

ow

w p

prro

op

pe

err

llo

occkko

ou

utt//tta

ag

go

ou

utt p

prro

occe

ed

du

urre

ess tto

o e

en

nssu

urre

e tth

he

e p

po

ow

we

err

cca

an

nn

no

ott b

be

e iin

na

ad

dv

ve

errtte

en

nttlly

y e

en

ne

errg

giizze

ed

d.. F

Fo

orr v

va

arriia

ab

blle

e

ffrre

eq

qu

ue

en

nccy

y d

drriiv

ve

ess o

orr o

otth

he

err e

en

ne

errg

gy

y sstto

orriin

ng

g

cco

om

mp

po

on

ne

en

nttss p

prro

ov

viid

de

ed

d b

by

y T

Trra

an

ne

e o

orr o

otth

he

errss,, rre

effe

err tto

o

tth

he

e a

ap

pp

prro

op

prriia

atte

e m

ma

an

nu

uffa

accttu

urre

err’’ss lliitte

erra

attu

urre

e ffo

orr

a

allllo

ow

wa

ab

blle

e w

wa

aiittiin

ng

g p

pe

erriio

od

dss ffo

orr d

diisscch

ha

arrg

ge

e o

off

cca

ap

pa

acciitto

orrss.. V

Ve

erriiffy

y w

wiitth

h a

a C

CA

AT

T IIIIII o

orr IIV

V v

vo

ollttm

me

ette

err

rra

atte

ed

d p

pe

err N

NF

FP

PA

A 7

70

0E

E tth

ha

att a

allll cca

ap

pa

acciitto

orrss h

ha

av

ve

e

d

diisscch

ha

arrg

ge

ed

d..

F

Fo

orr a

ad

dd

diittiio

on

na

all iin

nffo

orrm

ma

attiio

on

n rre

eg

ga

arrd

diin

ng

g tth

he

e ssa

affe

e

d

diisscch

ha

arrg

ge

e o

off cca

ap

pa

acciitto

orrss,, sse

ee

e P

PR

RO

OD

D--S

SV

VB

B0

06

6*

*--E

EN

N..

X39003892001A

N

No

otte

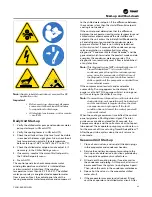

e:: Graphic labels (shown above) are used for CE

application only.

IIm

mp

po

orrtta

an

ntt::

•

Before servicing, disconnect all power

sources and allow at least 30 minutes

for capacitors to discharge.

•

All electrical enclosures—unit or remote

—are IP2X.

N

NO

OT

TIIC

CE

E

C

Ch

he

ecckk P

Pu

urrg

ge

e R

Ru

un

n--T

Tiim

me

e ffo

orr U

Un

niitt

H

He

errm

me

ettiicc IIn

ntte

eg

grriitty

y!!

F

Fa

aiillu

urre

e tto

o ffo

ollllo

ow

w iin

nssttrru

uccttiio

on

nss b

be

ello

ow

w cco

ou

ulld

d rre

essu

ulltt iin

n

cch

hiilllle

err d

da

am

ma

ag

ge

e..

IIff ffrre

eq

qu

ue

en

ntt p

pu

urrg

giin

ng

g iiss rre

eq

qu

uiirre

ed

d,, m

mo

on

niitto

orr p

pu

urrg

ge

e

p

pu

um

mp

po

ou

utt rra

atte

e,, a

an

nd

d iid

de

en

nttiiffy

y a

an

nd

d cco

orrrre

ecctt sso

ou

urrcce

e o

off

a

aiirr o

orr w

wa

atte

err lle

ea

akk a

ass sso

oo

on

n a

ass p

po

ossssiib

blle

e tto

o p

prre

ev

ve

en

ntt

m

mo

oiissttu

urre

e cco

on

ntta

am

miin

na

attiio

on

n cca

au

usse

ed

d b

by

y lle

ea

akka

ag

ge

e..

N

NO

OT

TIIC

CE

E

D

Do

o N

No

ott U

Usse

e N

No

on

n--C

Co

om

mp

pa

attiib

blle

e P

Pa

arrttss o

orr

M

Ma

atte

erriia

allss!!

U

Usse

e o

off n

no

on

n--cco

om

mp

pa

attiib

blle

e p

pa

arrttss o

orr m

ma

atte

erriia

allss cco

ou

ulld

d

rre

essu

ulltt iin

n e

eq

qu

uiip

pm

me

en

ntt d

da

am

ma

ag

ge

e..

O

On

nlly

y g

ge

en

nu

uiin

ne

e T

Trra

an

ne

e

®

®

rre

ep

plla

acce

em

me

en

ntt cco

om

mp

po

on

ne

en

nttss

w

wiitth

h iid

de

en

nttiicca

all T

Trra

an

ne

e p

pa

arrtt n

nu

um

mb

be

errss ssh

ho

ou

ulld

d b

be

e u

usse

ed

d

iin

n T

Trra

an

ne

e C

Ce

en

nT

Trra

aV

Va

acc cch

hiilllle

errss.. T

Trra

an

ne

e a

assssu

um

me

ess n

no

o

rre

essp

po

on

nssiib

biilliitty

y ffo

orr d

da

am

ma

ag

ge

ess rre

essu

ullttiin

ng

g ffrro

om

m tth

he

e u

usse

e

o

off n

no

on

n--cco

om

mp

pa

attiib

blle

e p

pa

arrttss o

orr m

ma

atte

erriia

allss..

This section describes the basic chiller preventive

maintenance procedures, and recommends the

intervals at which these procedures should be

performed. Use of a periodic maintenance program is

important to ensure the best possible performance and

efficiency from a CenTraVac

™

chiller.

N

No

otte

e:: Due to the pressure vessel codes applied to

CVHH CenTraVac

™

chillers, the bolts used for

both the economizer sump cover and the oil tank

cover are specified for both ASME and PED

application (SCREW, METRIC CAP-M16 x 70 mm

with FULL THREAD), HEAVY HEXAGON HEAD -

ASME SA-193M GRADE B7, ZINC PLATED.

D

Do

o n

no

ott ssu

ub

bssttiittu

utte

e!! Contact your local Trane

representative for replacement bolts.

This chiller utilizes Refrigerant Grade R-1233zd. Contact

your local Trane Service Agency for proper refrigerant:

•

Refrigerant MUST conform to Trane specification.

•

Confirm refrigerant supplied is Solstice ZD R-

1233zd Refrigerant Grade.

•

Confirm every container in shipment has the

marking "Solstice ZD” clearly displayed on the

vessel.

•

Verify Certificate of Analysis with each tank in

shipment.

Record Keeping Forms

An important aspect of the chiller maintenance

program is the regular completion of records. Refer to

“Appendix A: Forms and Check Sheets,” p. 118

for

copies of the recommended forms. When filled out

accurately by the machine operator, the completed

Summary of Contents for CVHH CenTraVac

Page 126: ...126 CVHH SVX001G EN N No ot te es s ...