Power Supply Wiring

CVHH-SVX001A-EN

59

Connect T1 to T6, T2 to T4, and T3 to T5.

N ot e: Bus bars are not needed in m edium -voltage or

high-voltage applications since only 3 term inals

are used in the m otor and starter.

Starter to Control Panel Wiring

The unit subm ittal includes the field w iring connection

diagram and the starter-to-control-panel connection

diagram (show ing the electrical connections required

betw een the rem ote-m ounted starter and the control

panel).

N ot e: Install separate conduit into the low voltage

(30 volts) section of the control panel.

When sizing and installing the electrical conductors for

these circuits, follow the guidelines listed. Use 14 AWG for

120V control circuits unless otherw ise specified. For AWG/

M CM equivalents in m m

2

, refer to

Table 12, p. 47

.

Im port ant :

M aintain at least 16 cm (6 in.) betw een low-

voltage (<30V) and high voltage circuits.

Failure to do so could result in electrical

noise that m ay distort the signals carried by

the low voltage w iring, including the IPC

w iring.

To w ire the starter to the control panel, follow the

guidelines below :

•

If the starter enclosure m ust be cut to provide electrical

access, exercise care to prevent debris from falling

inside the enclosure. Do not cut AFD enclosure.

•

Use only shielded, tw isted-pair w iring for the

Interprocessor Com m unication (IPC) circuit betw een

the starter and the control panel on rem ote m ounted

starters.

N ot e: Recom m ended w ire is Beldon Type 8760,

18 AWG for runs up to 304.8 m (1000 ft). For

AWG/M CM equivalents in m m

2

, refer to

Table 12, p. 47

. The polarity of the IPC w iring is

critical for proper operation.

•

Separate low-voltage (less than 30V; refer to

Table 13,

p. 48

) w iring from the 115V w iring by running each in

its ow n conduit.

•

When routing the IPC circuit out of the starter

enclosure, ensure that it is at least 16 cm (6 in.) from all

w ires carrying a higher voltage.

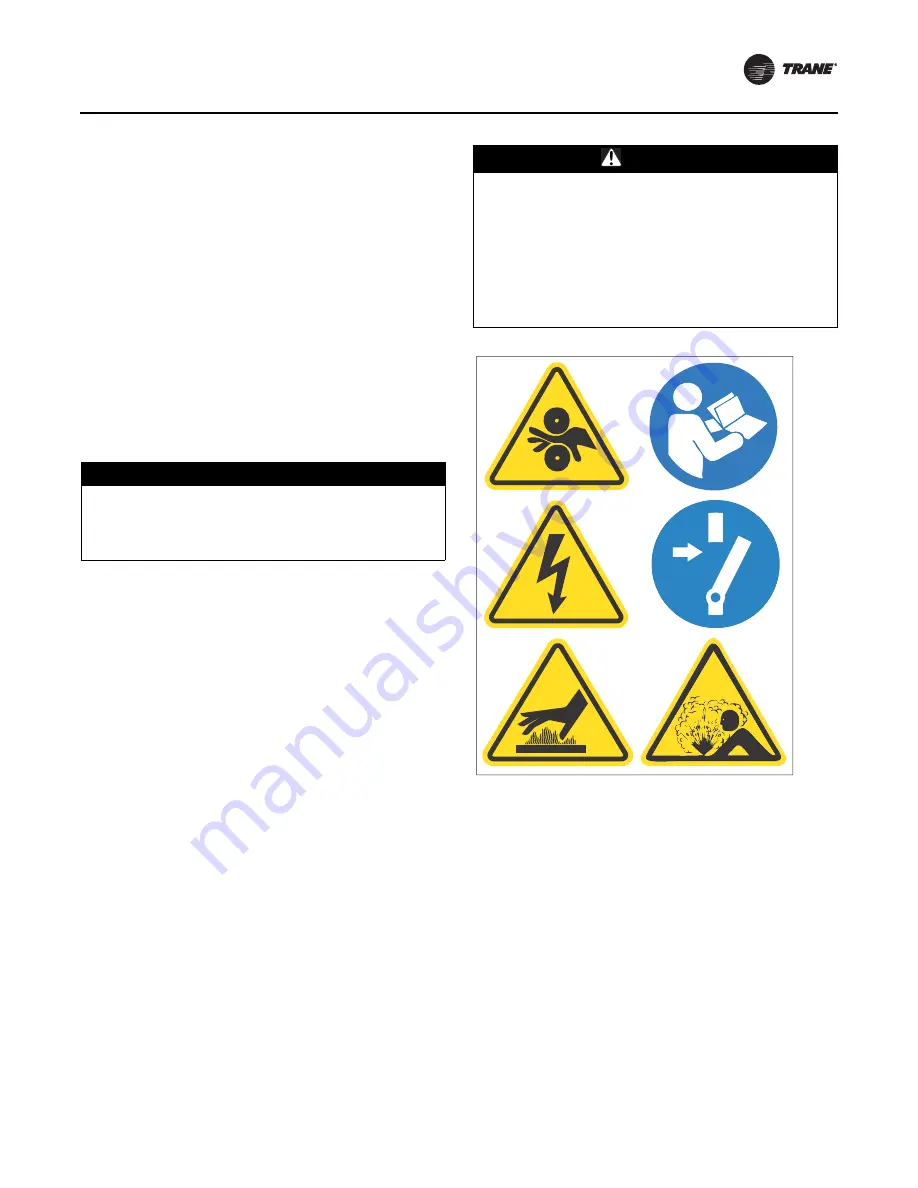

N ot e: Graphic labels (show n above) are used for CE

application only.

Im port ant :

•

Before servicing, disconnect all pow er sources and

allow at least 30 m inutes for capacitors to discharge.

•

All electrical enclosures—unit or rem ote—are IP2X.

•

The IPC w iring shield should be grounded on one end

only at control panel end.The other end should be un-

term inated and taped back on the cable sheath to

prevent any contact betw een shield and ground.

•

Oil Pum p Interlock: All starters m ust provide an

interlock (norm ally open) contact w ith the chiller oil

pum p connected to the control panel at term inals

1X1-10 and 1X1-21 (14 AWG; for AWG/M CM

equivalents in m m

2

, refer to

Table 12, p. 47

.) The

purpose of this interlock is to m aintain the oil pum p

signal in the event that a starter failure, such as w elded

contacts, keeps the chiller m otor running after the

controller interrupts the run signal.

NOTICE:

Component Damage!

Remove all debris from inside the starter panel. Failure

to do so could result in an electrical short and could

cause serious starter component damage.

WARNING

Proper Field Wiring and Grounding

Required!

Failure to follow code could result in death or serious

injury. All field w iring M UST be performed by qualified

personnel. Improperly installed and grounded field

w iring poses FIRE and ELECTROCUTION hazards. To

avoid these hazards, you M UST follow requirements for

field w iring installation and grounding as described in

NEC and your local/ state/ national electrical codes.

X39003892001A

Summary of Contents for CVHH

Page 110: ......