22

18-CD19D5-25

Installer’s Guide

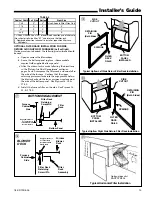

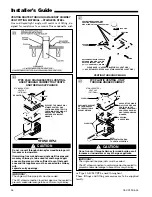

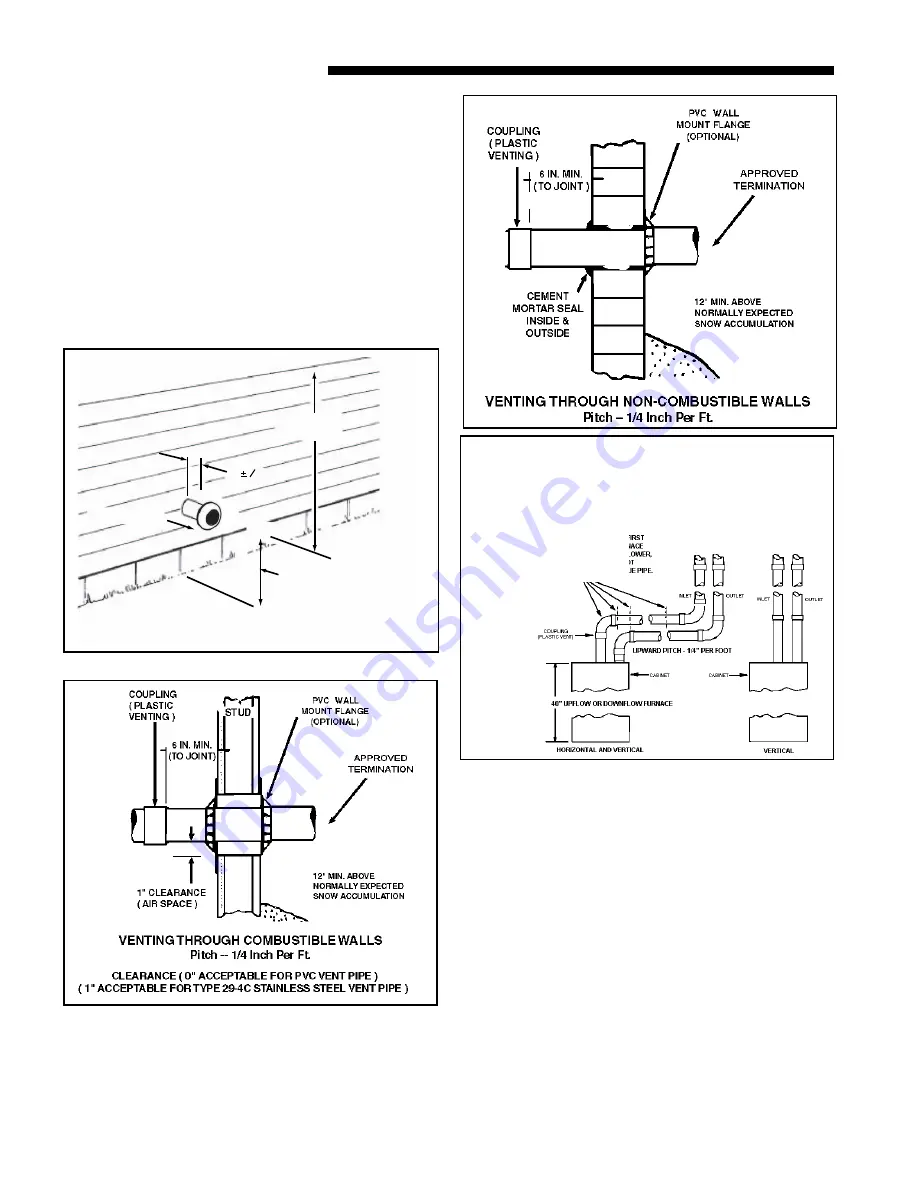

PITCH –

Venting through the wall must maintain 1/4"

per foot pitched upward to insure that condensate

drains back to the furnace.

FLUE GAS DEGRADATION –

The moisture content

of the flue gas may have a detrimental effect on some

building materials. This can be avoided by using the

roof or chimney venting option. When wall venting is

used on any surface that can be affected by this mois-

ture, it is recommended that a corrosion resistant

shield (24 inches square) be used behind the vent termi-

nal. This shield can be wood, plastic, sheet metal, etc.

Also, silicone caulk all cracks, seams and joints within 3

feet of the vent terminal.

COMBUSTION

AIR

VENT

12" MIN TO

OVERHANG

1"

MAINTAIN 12 IN

(18 IN. FOR CANADA)

MINIMUM CLEARANCE

ABOVE HIGHEST

ANTICIPATED SNOW

LEVEL OR GRADE

WHICHEVER IS GREATER

1

2

"

BAYAIR30AVENTA

(Sidewall)

;

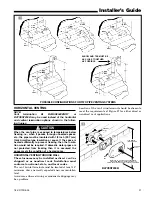

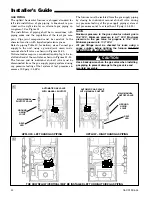

COMBUSTIBLE MATERIAL WALL

A minimum clearance of 1" to combustible materials

must be maintained when using single wall stainless

steel venting. See Figure 32.

Shield material to be a minimum of 24 gauge stainless

or aluminized sheet metal. Minimum dimensions are

12"x12". Shield must be fastened to both inside and out-

side of wall. Use screws or anchor type fasteners suited

to the outside or inside wall surfaces.

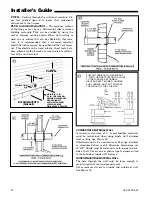

NONCOMBUSTIBLE MATERIAL WALL

The hole through the wall must be large enough to

maintain pitch of vent and properly seal.

Use cement mortar seal on inside and outside of wall.

See Figure 33.

c

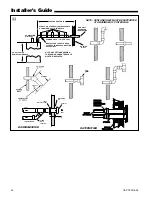

SUPPORT HORIZONTAL PIPE EVERY 3'

0" WITH THE FIRST SUPPORT AS CLOSE

TO THE FURNACE AS POSSIBLE.

INDUCED DRAFT BLOWER, HOUSING,

AND FURNACE MUST NOT SUPPORT

THE WEIGHT OF THE FLUE PIPE.

z

x