10

18-CD31D1-5

Installer’s Guide

TABLE 4

UPFLOW FURNACE RETURN AIR FILTERS

CABINET

WIDTH

QTY*

CABINET

BOTTOM FILTER

CABINET

SIDE FILTER

17-1/2"

1

17" X 25" X 1"

17-1/2" X 25" X 1"

21"

1

20" X 25" X 1"

17-1/2" X 25" X 1"

24-1/2"

1

24" X 25" X 1"

17-1/2" X 25" X 1"

*First letter may be "A" or "T"

**NOTE: For upflow 5 ton airflow models where the airflow

requirement exceeds 1800 CFM - Models will require return

air openings and filters on: (1) both sides, or (2) one side and

the bottom, or (3) just on the bottom

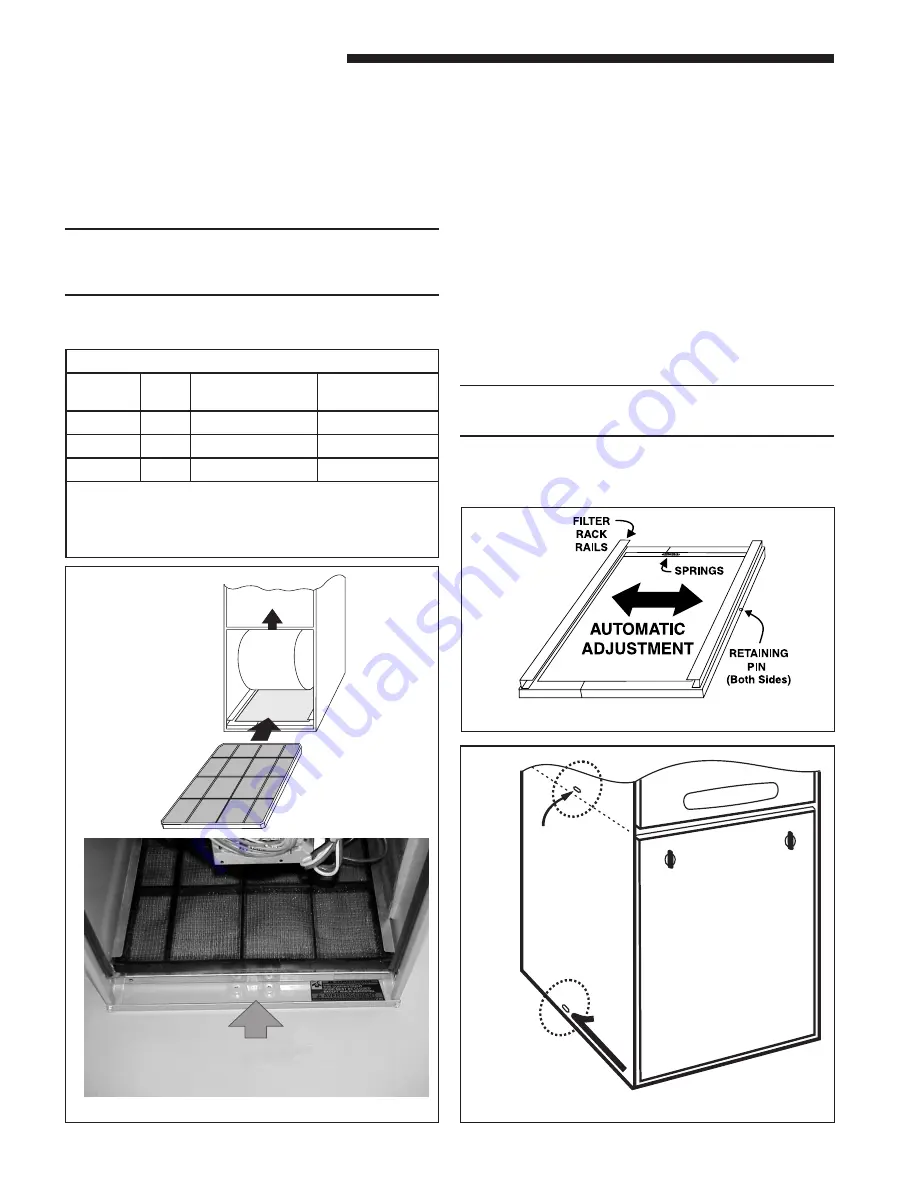

BOTTOM FILTER RACK INSTALLATION

Airflow

RETURN AIR FILTERS

TYPICAL UPFLOW RETURN AIR FILTER INSTALLATIONS

Filters are factory supplied for these furnaces. These

furnaces require high velocity type air filters. The filters

may be located within the furnace blower compartment for

UPFLOW furnaces in either a BOTTOM or SIDE (left side

or right side) return air inlet. Some filters may need to be

trimmed for side or bottom filter use.

NOTE: For upflow 5 ton airflow models where the airflow

requirement exceeds 1800 CFM - Models will require re-

turn air openings and filters on: (1) both sides, or (2) one

side and the bottom, or (3) just the bottom.

The furnace and the bottom filter rack, BAYRACK960,

installation can be seen in Figures 13, 14 and 15.

Airflow

e

VIEW

ENGAGEMENT

HOLE DETAIL

(Typical both sides

and blower deck)

Blower Deck

Engagement

Hole

t

Filter Rack Assembly

r

ALTERNATE FILTER RACK INSTALLATION FOR BOTTOM

RETURN

The following checklist should be used when installing a

bottom return filter on an upflow furnace:

a. Remove the filter.

b. Remove the bottom panel.

c. With the filter removed, the filter rack is compressed

and then inserted into the bottom of the furnace.

The retaining screw/pin on each side inserts into en-

gagement holes at the bottom of the furnace cabinet

side.

d. Reinstall the furnace filter in the bottom position by

inserting the chamfer end first into the filter rack.

See Figures 13-16.

NOTE: There is no internal right side filter access with

the use of the filter rack on furnace models *UD060R9V3,

*UD2C080B9V4VA, and *UD2C100B9V5VA.