18-CD29D1-3

17

Installer’s Guide

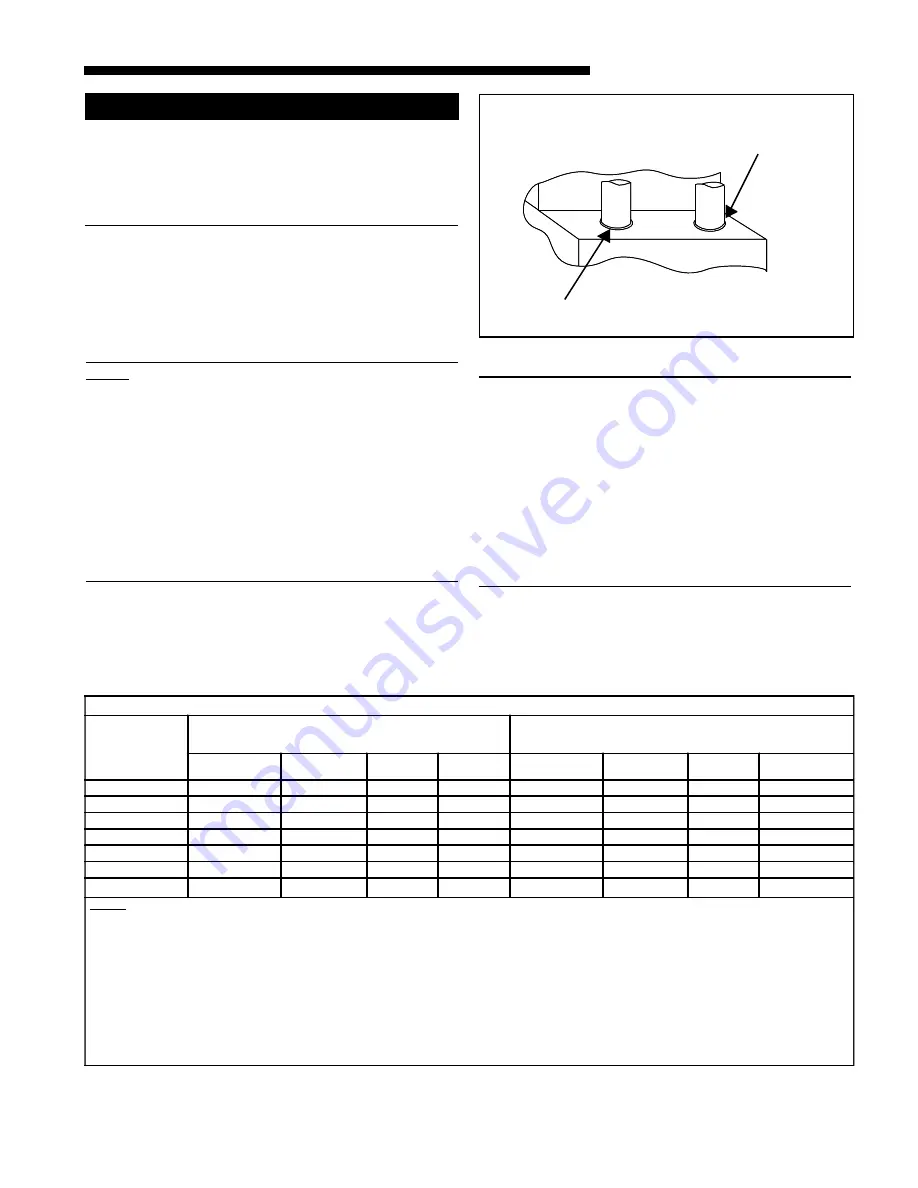

Seal

VENT PIPE

with RTV sealant

Seal

INLET AIR PIPE

with RTV sealant

Front of Furnace

VENT AND INLET AIR CONNECTIONS

f

Connection of the

vent pipe

to the vent collar should

also be accomplished using RTV type sealant. This type

sealant provides a connection which remains flexible

and can be separated in the future if service needs re-

quire the removal of the vent pipe for service or clear-

ance. See Figure 24.

NOTE:

To ensure proper operation at the vent lengths indi-

cated, the combustion air inlet and vent terminals

should be in the same pressure zone. Terminating the

vent and inlet in different pressure zones will change

the maximum vent lengths and may cause nuisance

tripping of the pressure switch(es). The amount of

change can not be predicted. The selection of the inlet

and outlet terminal locations are the responsibility of

the designer/installer. If the installer chooses separate

pressure zones for the terminals, the combustion air

inlet termination must be in the higher (more positive)

pressure zone.

MAXIMUM VENT LENGTH:

MODEL

DIRECT VENT (2 PIPE SYSTEM) -

MAXIMUM TOTAL EQUIVALENT FEET FOR

VENT AND INLET AIR PIPES (See Notes)

NONDIRECT VENT (1 PIPE SYSTEM) -MAXIMUM TOTAL

EQUIVALENT FEET FOR

VENT PIPE ONLY (See Notes)

2" PIPE

& FITTINGS

2-1/2" PIPE

& FITTINGS

3" PIPE

& FITTINGS

4" PIPE

& FITTINGS

2" PIPE

& FITTINGS

2-1/2" PIPE

& FITTINGS

3" PIPE

& FITTINGS

4" PIPE

& FITTINGS

*UH1B040A9241A

60

80

100

130

50

80

80

130

*UH1B060A9361A

60

80

100

130

50

80

80

130

*UH1B080A9421A

40

80

100

130

30

80

80

130

*UH1C080A9601A

NOT ALLOWED

NOT ALLOWED

70

130

NOT ALLOWED

NOT ALLOWED

50

130

*UH1C100A9481A

NOT ALLOWED

NOT ALLOWED

90

130

NOT ALLOWED

NOT ALLOWED

70

130

*UH1D100A9601A

NOT ALLOWED

NOT ALLOWED

90

130

NOT ALLOWED

NOT ALLOWED

70

130

*UH1D120A9601A

NOT ALLOWED

NOT ALLOWED

50

130

NOT ALLOWED

NOT ALLOWED

30

130

NOTES:

* - First letter may be "A" or "T"

1. The INLET AIR of one pipe systems require the installation of a 90° elbow (to prevent dust and debris from falling straight into thefurnace) and a 2 foot

horizontal or vertical straight pipe section connected before or after the elbow.

2. DO NOT MIX PIPE DIAMETERS IN THE SAME LENGTH OF PIPE OUTSIDE THE FURNACE CABINET (Except adapters at the top of the furnace).

If different inlet and vent pipe sizes are used, the vent pipe must adhere to the maximum length limit shown in the table above (See Note 7 below for exception).

The inlet pipe can be of a larger diameter, but never smaller than the vent pipe.

3. MAXIMUM PIPE LENGTHS MUST NOT BE EXCEEDED! THE LENGTH SHOWN IS NOT A COMBINED TOTAL, IT IS THE MAXIMUM LENGTH OF EACH

(Vent or Inlet air pipes in two pipe systems).

4. One standard radius 90° elbow is equivalent to 12' of 4" pipe; one SHORT radius 90° elbow is equivalent to 10' of 3" pipe and one LONG radius elbow is

equivalent to 6' of 3" pipe. One SHORT/LONG radius 90° elbow is equivalent to 7½' of 2½" pipe, & 5' of 2" pipe. Two 45° elbows equal one 90°elbow.

5. The termination tee or bend must be included in the total number of elbows. If the BAYAIR30AVENTA termination kit is used, the equivalent length of pipe is 5 feet.

There is zero equivalent length for the BAYVENT200.

6. Pipe adapters are field supplied.

7. 4" pipe may be reduced to 3" for termination with BAYAIR30AVENTA or BAYVENT200 without additional length restriction.

8. For Canadian applications ONLY, IPEX 196006 may be used for horizontal and vertical terminations. IPEX 081216, IPEX 081218, and IPEX 081219 may only be used for

horizontal vent terminations. Equivalent lengths are IPEX 196009 = 5 feet, IPEX 081216 = 11 feet, IPEX 081218 = 16 feet, and IPEX 081219 = 21 feet.

UPFLOW/ HORIZONTAL VENTING TABLE

TABLE 11

IMPORTANT:

Products installed in Canada must use vent systems

that are certified to the Standard for Type BH Gas Vent-

ing Systems (ULC S636) for Class II-A venting systems

(up to 65°C). Components of the vent system must not

be interchanged with other vent systems or unlisted

pipe or fittings. Plastic components, specified prim-

ers, and glues must be from a single system manufac-

turer and not intermixed with other system

manufacturer's vent system parts. In addition, the first

three feet of the vent pipe must be visible for inspec-

tion.

▲

WARNING

!

CARBON MONOXIDE POISONING HAZARD

Do not replace any of the factory supplied venting

components with field fabricated parts. Failure to fol-

low this safety warning exactly could result in dam-

aged vents, damaged components, carbon monoxide

poisoning, or death.