18-CD30D1-12

25

Installer’s Guide

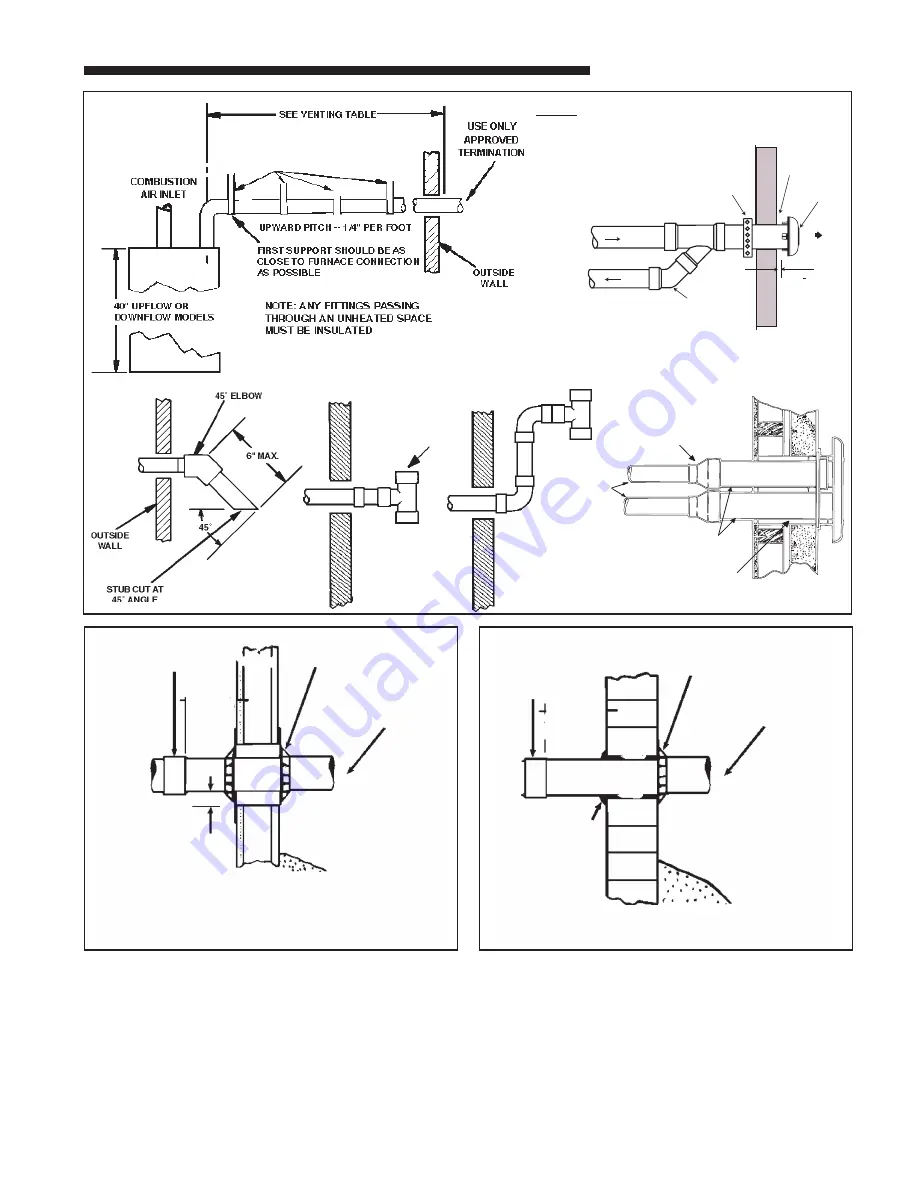

COMBUSTIBLE MATERIAL WALL

A minimum clearance of 1" to combustible materials must

be maintained when using single wall stainless steel

venting. See Figure 32.

Shield material to be a minimum of 24 gauge stainless

or aluminized sheet metal. Minimum dimensions are

12"x12". Shield must be fastened to both inside and out-

side of wall. Use screws or anchor type fasteners suited

to the outside or inside wall surfaces.

NONCOMBUSTIBLE MATERIAL WALL

The hole through the wall must be large enough to main-

tain pitch of vent and properly seal.

Use cement mortar seal on inside and outside of wall.

See Figure 33.

COUPLING

(PLASTIC

VENTING)

STUD

PVC WALL

MOUNT FLANGE

(OPTIONAL)

APPROVED

TERMINATION

1” CLEARANCE

(AIR SPACE)

VENTING THROUGH COMBUSTIBLE WALLS

Pitch - 1/4 Inch Per Foot

CLEARANCE (0” ACCEPTABLE FOR PVC VENT PIPE)

(1” ACCEPTABLE FOR TYPE 29-4C STAINLESS STEEL VENT PIPE)

12” MINIMUM ABOVE

NORMALLY EXPECTED

SNOW ACCUMULATION

LEVEL

6 IN. MIN.

(TO JOINT)

x

COUPLING

(PLASTIC

VENTING)

PVC WALL

MOUNT FLANGE

(OPTIONAL)

APPROVED

TERMINATION

CEMENT

MORTAR SEAL

INSIDE &

OUTSIDE

VENTING THROUGH NON-COMBUSTIBLE WALLS

Pitch - 1/4 Inch Per Foot

12” MINIMUM ABOVE

NORMALLY EXPECTED

SNOW ACCUMULATION

LEVEL

6 IN. MIN.

(TO JOINT)

c

NOTE: VENT AND INLET MUST BE SUPPORTED

AT A MAXIMUM OF 3' INTERVALS

BAYAIR30AVENTA

3" PIPING

2", 2-1/2"

or 3" PIPING

REDUCING

COUPLING,

FIELD SUPPLIED

IF NEEDED

SEAL ALL

WALL CAVITIES

BAYVENT200B

TEE

STRAPS OR OTHER SUITABLE SUPPORTS

AT A MAXIMUM OF 3' 0" INTERVALS

z

RAIN CAP

COMBUSTION AIR

STRAP

(FIELD SUPPLIED)

COMBUSTION

AIR

VENT

ELBOW

(FIELD

SUPPLIED)

VENT

1" + 1/2"

CONCENTRIC VENT

SIDE WALL INSTALLATION

For Canadian applications only, IPEX

196006, IPEX 081216, IPEX 081218,

and IPEX 081219 may be used for hori-

zontal vent terminations.