6

ACC-SVN232A-EN

Installation

Field Installed Option

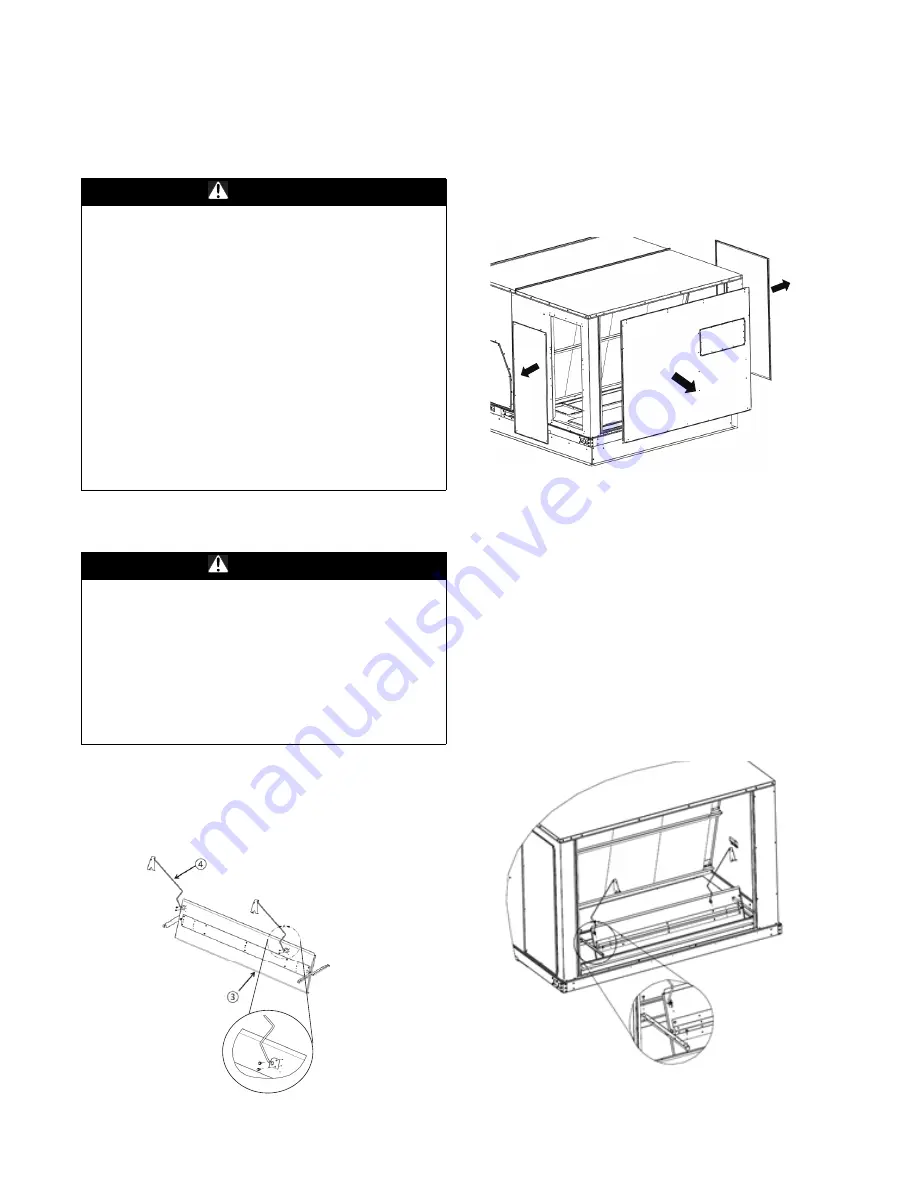

1. Assemble connecting rods 4 to return air damper 3 by

aligning holes 1 and 2, and attach rods using two

screws as shown below.

2. Remove the filter/fan compartment access panel and

the unit end panel (evaporator end).

a. Place the return air damper assembly into the

return air opening as illustrated in

. Confirm

damper is positioned with the sheet metal lip in the

upward position.

b. Attach the pivotal brackets to the unit using two

screws per bracket.

c. Raise the damper and rods into the vertical

position. Position the connecting rods against the

filter rack to prevent them from interfering with the

economizer. See

d. Confirm damper is positioned with sheet metal lip

in the upward position as illustrated in following

figure.

WARNING

Hazardous Service Procedures!

Failure to follow all precautions in this manual and on

the tags, stickers, and labels could result in death or

serious injury.

Technicians, in order to protect themselves from

potential electrical, mechanical, and chemical hazards,

MUST follow precautions in this manual and on the

tags, stickers, and labels, as well as the following

instructions: Unless specified otherwise, disconnect all

electrical power including remote disconnect and

discharge all energy storing devices such as capacitors

before servicing. Follow proper lockout/tagout

procedures to ensure the power can not be

inadvertently energized.When necessary to work with

live electrical components, have a qualified licensed

electrician or other individual who has been trained in

handling live electrical components perform these

tasks.

WARNING

Hazardous Voltage w/Capacitors!

Failure to disconnect power and discharge capacitors

before servicing could result in death or serious injury.

Disconnect all electric power, including remote

disconnects and discharge all motor start/run

capacitors before servicing. Follow proper lockout/

tagout procedures to ensure the power cannot be

inadvertently energized. Verify with a CAT III or IV

voltmeter rated per NFPA 70E that all capacitors have

discharged.

Figure 2.

Assemble connecting rods

1

2

Figure 3.

Remove panels

Figure 4.

Install return air damper assembly

Summary of Contents for FIAECON003 Series

Page 11: ...Notes ACC SVN232A EN 11...