Page 23

9. ELECTRICAL PANEL AND ELECTRICAL DATA

When reviewing this manual keep in mind.

• All field-installed wiring must be in accordance with local regulations, CE directives and guidelines. Be sure to

satisfy proper equipment grounding requirements.

• The standardized values - Maximum Amps –Maximum kWatts are displayed on unit nameplate.

• All field-installed wiring must be checked for proper terminations, and for possible shorts or grounds.

Ensure total protection against the possible penetration of water into the connection point.

All the cables and the terminals are univocally numbered according to the electrical scheme to avoid possible

misinterpretation. The identification system of the cables connected to the components allow also an easy and

intuitive recognition of the component. Each component of the electrical panel is provided with an identification

plate according to what is shown on the electrical scheme. All the connections to the electrical panel are made

from the bottom and are equipped with cover preventing from break. The electrical panel supply is 400V/3ph/50Hz

so, no additional power supply is necessary. The entrance for the power cables is provided on the bottom of the

box where a dismountable flange suitable for the purpose is provided.

The control circuit is powered with 24 VDC. Each unit is provided with auxiliary transformer control circuit

230/27VAC. It requires no additional power cable for the control equipment.

The unit has an antifreeze heater installed directly into the evaporator. The circuit also has an electric resistance

installed in the compressor to keep the oil warm and avoid the transmigration of the refrigerant in its interior.

Obviously, the operation of the electrical resistors is ensured as long as the unit is power supplied.

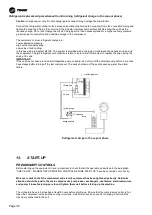

The unit is equipped with an alarm relay, which changes state every time an alarm occurs in one of the cooling

circuits. Connect the terminals as per the wiring diagram on the unit - terminal “X” - a visual or audible alarm or

any external supervision system.

BMS to monitor its operation is allowed. See the wiring diagram of the unit for wiring.

WARNING

To avoid corrosion, overheating or general damage, at terminal connections, unit is designed for copper

conductors only. In case of aluminum conductors an intermediate connection box must be added. In case of aluminum

cable bi material connecting device is mandatory. Cable routing inside control panel should be made

case by case by installer.

WARNING

Hazardous Voltage with Capacitor! Disconnect all electric power, including remote disconnects and

discharge all motor start/run and capacitors before servicing. Follow proper lock out/tag out procedures to ensure

the power cannot be inadvertently energized.

For variable frequency drives or other energy storing components provided by Trane or others, refer to the

appropriate manufacturer’s literature for allowable waiting periods for discharges capacitors. Verify with an

appropriate voltmeter that all capacitors have discharged.

After disconnecting input power, wait five (5) minutes for units which are equipped with variable frequency drive

(0V DC) before touching any internal components. Failure to follow these instructions could result in death or

serious injury.

IMPORTANT

if the unit is powered by a TT power supply system a differential protection should be suited for industrial

machinery with current leak than can be higher than 500 mA (several motors and frequency drives)

VERY IMPORTANT

due to the fact that the unit doesn’t mount a refrigerant high pressure safety valve and therefore the

safety device for a high pressure event is the high pressure switch, shunt trip coils are installed on compressors automatic

circuit breakers in order to ensure the compressors stop in case a high pressure event should occur and in the same

moment the electronic control shouldn’t work properly.

This implies that if a high pressure event should occur a manual

reset of the compressors automatic circuit breakers is needed.

Summary of Contents for FLEX HP HT

Page 2: ...Page 2 ...

Page 3: ......