Page 33

STARTING UP

All the compressors mounted on Trane units are factory charged with oil whose chemical characteristic of stability are very

good, so it is not necessary to change frequently the lubricant oil.

The scroll compressors are equipped with an oil sight glass from which you can control the level. In tandem or trio

performances, pay particular attention to oil level. Not perfectly leveled sight glasses between compressors in parallel, but

falling in the upper and lower limits, are considered normal.

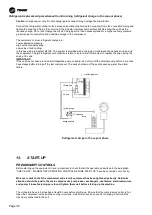

Next to the lamp there is a connection on every compressor for draining the oil and a connection for refilling.

To refill oil, there is a ¼” Schrader connection.

To refill oil, it is necessary to discharge the refrigerant in the unit, recovering it in adequate cylinders. Then vacuum until you

reach a pressure of about 6 Pa to remove any trace of humidity from the circuit. Then load the unit with a small amount of

refrigerant and fill oil from the proper connection for refilling.

Add oil until the oil sight glass is flat within the upper and lower limits indicated by the corresponding notches.

At this point refill the previously discharged amount of refrigerant as in the indications above. Restart the compressor.

Run for 20 minutes at full load and check the oil level. The units use POE oil.

In case of burns for the electrical motor or fault of the compressor, it is necessary to make a test to check the acidity of the

lubricant oil and, eventually, clean the circuit to reduce the acidity to correct values, mounting for instance an antiacid filter

and changing the oil in the circuit.

WARM UP OF THE PLANT

In order to keep all components in good condition and to optimise their use, during the warm up it is necessary to bring the

circuit to the right temperature before releasing cooling energy to the utilities.

The following steps must be followed for this to be carried out:

- start up the machine

- wait for the water in temperature to reach the running temperature

- start up the user side (i.e. terminal units)

Follow the above-mentioned procedure every time the plant is stopped long enough for the water temperature contained in it

to vary considerably.

START UP PROCEDURE

•

With the switch closed, open the electrical panel and exclude compressor (refer to the wiring diagram on the

unit). Close the panel, set switch to “ON” (to give power to the unit).

•

Wait for the start of the microprocessor and control. Make sure that the temperature of the oil is hot enough.

Oil fill

connection and

gauge port

Oil sight

glass

Oil drain

connection

Summary of Contents for FLEX HP HT

Page 2: ...Page 2 ...

Page 3: ......