CTV-SVX009D-GB

39

11

UNT-PRC002-GB

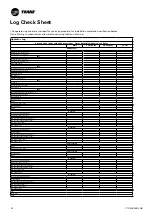

Sound power levels

Discharge

Measurement conditions:

Measurements taken in a room adjacent to the room containing the FWD, at the outlet of the rectangular duct (1.5 m

long) fixed to its discharge opening.

Fan

Power level in dB(A), per Hz frequency band

Overall power

Unit

speed

125

250

500

1000

2000

4000

8000

dB(A)

1

55

50

42

37

37

31

30

46

FWD 08

2

57

54

47

40

30

38

40

50

3

58

57

50

42

32

40

43

53

1

57

51

45

42

34

33

28

48

FWD 10

2

58

54

48

45

38

39

35

51

3

60

58

50

48

40

42

39

54

1

57

51

45

42

34

33

28

48

FWD 12

2

58

54

48

45

38

39

35

51

3

60

58

50

48

40

42

39

54

1

56

62

50

48

39

38

36

56

FWD 14

2

61

66

55

53

47

46

45

60

3

63

69

58

56

50

50

49

63

1

57

63

51

49

40

39

37

57

FWD 20

2

61

66

55

53

47

46

45

60

3

63

69

58

56

50

50

49

63

Intake

Measurement conditions:

Measurements taken at the horizontal air intake.

Fan

Power level in dB(A), per Hz frequency band

Overall power

Unit

speed

125

250

500

1000

2000

4000

8000

dB(A)

1

56

55

55

53

46

45

42

57

FWD 08

2

63

62

60

60

53

53

53

64

3

66

65

63

62

56

55

57

67

1

62

58

55

58

51

48

44

61

FWD 10

2

66

63

60

62

56

55

52

66

3

70

67

63

65

59

59

57

69

1

62

58

55

58

51

48

44

61

FWD 12

2

66

63

60

62

56

55

52

66

3

70

67

63

65

59

59

57

69

1

66

65

65

65

57

50

46

68

FWD 14

2

73

72

69

71

64

59

57

74

3

78

76

73

75

69

64

63

78

1

68

72

64

64

56

52

50

69

FWD 20

2

76

76

68

71

65

61

61

75

3

78

79

71

74

69

66

66

78

Installer-Supplied Components

Customer wiring interface connections are shown in

the electrical schematics and connection diagrams that

are shipped with the unit. The installer must provide the

following components if not ordered with the unit:

• Power supply wiring (in conduit) for all field-wired

connections

• All control (interconnecting) wiring (in conduit) for field

supplied devices

• Fused-disconnect switches

Power Supply Wiring

All power supply wiring must be sized and selected

accordingly by the project engineer in accordance with

standard IEC 60364. All wiring must comply with local codes.

The installing (or electrical) contractor must provide and

install the system interconnecting wiring, as well as-the

power supply wiring. It must be properly sized and equipped

with the appropriate fuse-disconnect switches. The type and

installation location(s) of the fused-disconnect switches must

comply with all applicable codes.

Cut holes into the sides of the control panel for the

appropriately-sized power wiring conduits. The wiring

is passed through these conduits and connected to the

terminal blocks.

To provide proper phasing of 3 phase input, make

connections as shown in field wiring diagrams and as stated

on the yellow WARNING label in the starter panel. Proper

equipment grounds must be provided to each ground

connection in the panel

CAUTION!

Customer wiring interface connections are shown

in the electrical schematics and connection diagrams that

are shipped with the unit. The installer must provide the

following components if not ordered with the unit.

WARNING!

To prevent injury or death, disconnect all

electrical power sources before completing wiring

connections to the unit.

CAUTION!

The use of copper mono-conductors is the

preferred solution to avoid corrosion and overheating

at terminal connections.

Control Power Supply

Chiller is provided with control power transformer, it is not

necessary to provide additional control power voltage to the

unit.

Heater Power Supply

The evaporator shell is insulated from ambient air and

protected from freezing for temperature down to -20°C

by two thermostatically-controlled immersion heaters

combined with evaporator pumps activation through Tracer

UC800. Whenever the ambient temperature drops below 0°C

the thermostat energizes the heaters and the Tracer UC800

activates the pumps. If ambient temperatures below -20°C

are expected, contact your Trane local office.

CAUTION!

The control panel main processor does not

check for loss of power to the heat tape nor does it verify

thermostat operation. A qualified technician must frequently

verify power to the heat tape and confirm operation of the

heat tape thermostat, to avoid catastrophic damage to the

evaporator.

CAUTION!

With factory-fitted disconnect switch, trace

heating is taken from the live side of the isolator so power

remains on. Supply voltage to the heating tapes is 400V.

In case of winter water drainage for freeze protection, it is

compulsory to disconnect the evaporator heaters to protect

them from burning due to overheat.

Water Pump Power Supply

Provide power-supply wiring with fused disconnect

switch(es) for the chilled water pump(s).

Interconnecting Wiring

Chilled-Water Flow (Pump) Interlock

GVAF requires a field-supplied, control-voltage contact

input through a flow proving switch (6S51) and an auxiliary

contact (6K51). Connect the proving switch and auxiliary

contact to terminal 2 connector J2 cards (1A14). Refer to the

field wiring diagram for details.

Chilled-Water Pump Control

An evaporator water-pump output relay closes when

the chiller is given a signal to go into the AUTO mode of

operation from any source. The contact is opened to turn off

the pump in the event of most machine-level diagnostics, to

prevent the buildup of pump heat.

CAUTION!

The evaporator water pump output relay must be

used to control the chilled water pump and to benefit from

the water pump timer function at startup and shutdown of

the chiller. This is required when the chiller is in operation

under freezing conditions, especially if the chilled water loop

does not contain glycol.

CAUTION!

Refer to Freeze Protection section for information

about the evaporator circulating pump.