Installation

RT-SVX35H-EN

35

Note:

Gas pressure in excess of 14" w.c. or 0.5 psig will

damage the gas train.

Failure to use a pressure regulating device will result in

incorrect gas pressure. This can cause erratic operation

due to gas pressure fluctuations as well as damage the gas

valve. Over sizing the regulator will cause irregular

pulsating flame patterns, burner rumble, potential flame

outages, and possible gas valve damage.

If a single pressure regulator serves more than one rooftop

unit, it must be sized to ensure that the inlet gas pressure

does not fall below 7" w.c. with all the furnaces operating

at full capacity. The gas pressure must not exceed 14" w.c.

when the furnaces are off.

7. Provide adequate support for all field installed gas

piping to avoid stressing the gas train and controls.

8. Leak test the gas supply line using a soap-and-water

solution or equivalent before connecting it to the gas

train.

9. Check the supply pressure before connecting it to the

unit to prevent possible gas valve damage and the

unsafe operating conditions that will result.

Note:

Do not rely on the gas train shutoff valves to isolate

the unit while conducting gas pressure/leak test.

These valves are not designed to withstand

pressures in excess of 14" w.c. or 0.5 psig.

WARNING

Hazard of Explosion!

Never use an open flame to detect gas leaks. It could

result in an explosion. Use a leak test solution for leak

testing. Failure to follow recommended safe leak test

procedures could result in death or serious injury or

equipment or property-only-damage.

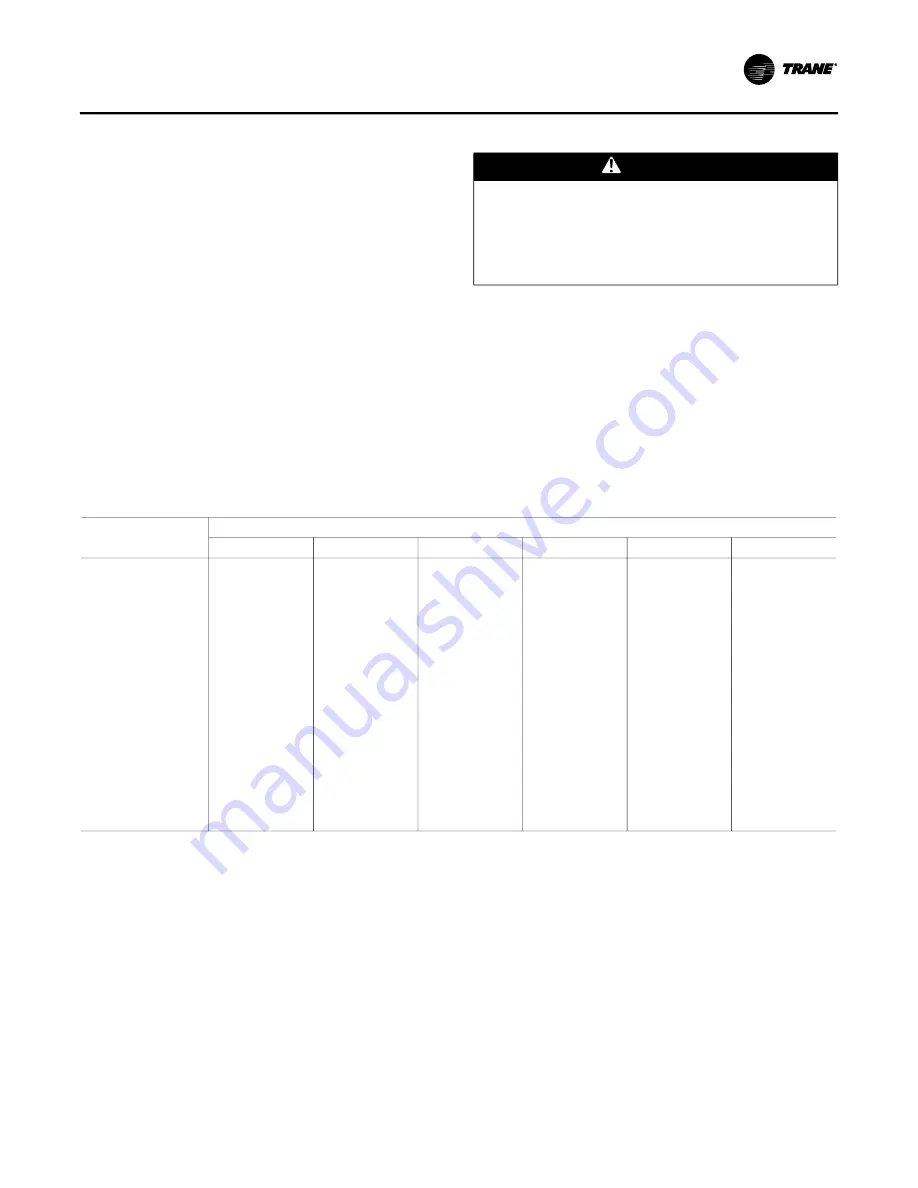

Table 6.

Sizing natural gas pipe mains & branches

Gas Supply Pipe

Run (ft)

Gas Input (Cubic Feet/Hour)

(a)

1-1/4” Pipe

1-1/2” Pipe

2” Pipe

2-1/2” Pipe

3” Pipe

4” Pipe

10

1050

1600

3050

4800

8500

17500

20

730

1100

2100

3300

5900

12000

30

590

890

1650

2700

4700

9700

40

500

760

1450

2300

4100

8300

50

440

670

1270

2000

3600

7400

60

400

610

1150

1850

3250

6800

70

370

560

1050

1700

3000

6200

80

350

530

990

1600

2800

5800

90

320

490

930

1500

2600

5400

100

305

460

870

1400

2500

5100

125

275

410

780

1250

2200

4500

150

250

380

710

1130

2000

4100

175

225

350

650

1050

1850

3800

200

210

320

610

980

1700

3500

Notes:

1.

If more than one unit is served by the same main gas supply, consider the total gas input (cubic feet/hr.) and the total length when determining the

appropriate gas pipe size.

2.

Obtain the Specific Gravity and BTU/Cu.Ft. from the gas company.

3.

The following example demonstrates the considerations necessary when determining the actual pipe size.

Example: A 40' pipe run is needed to connect a unit with a 500 MBH furnace to a natural gas supply having a rating of 1,000

BTU/Cu.Ft. and a specific gravity of 0.60

Cu.Ft/Hour = Furnace MBH Input

Gas BTU/Cu.Ft. X Multiplier (

Table 6, p. 30

)

Cu.Ft/Hour = 500

Table 6, p. 30

indicates that a 1-1/4" pipe is required.

(a) Table is based on a specific gravity of 0.60. Use Table 3-1 for the specific gravity of the local gas supply.

Summary of Contents for IntelliPak WEHE Series

Page 15: ...General Information RT SVX35H EN 15 Figure 1 Unit component layout and ship with locations...

Page 17: ...Installation RT SVX35H EN 17 Figure 2 Typical control module location...

Page 44: ...Installation 44 RT SVX35H EN Figure 27 Typical field power wiring for W_HE casings 2 through 6...

Page 56: ...Installation 56 RT SVX35H EN Figure 32 Wiring notes for CV controls...

Page 60: ...Installation 60 RT SVX35H EN Figure 35 Wiring notes VAV...

Page 68: ...System Start up 68 RT SVX35H EN Figure 38 Typical fenwall ignition control system...

Page 69: ...System Start up RT SVX35H EN 69 Figure 39 Typical Fenwall ignition control system...