Installation

38

RT-SVX35H-EN

Hot Water Heat Units (WLHE)

Hot water heating coils are factory installed inside the

heater section of the unit. Once the unit is set into place,

the hot water piping and the three way modulating valve

(factory provided, field installed) must be installed. The

valve can be installed inside the heat section or near the

unit. If the valve is installed in a remote location, use field

supplied wiring to extend the control wires from the heater

section to the valve. Two access holes are provided in the

unit base as shown in

.

Following the guidelines listed below will enhance both

the installation and operation of the "wet heat" system.

illustrates the recommended piping

configurations for the hot water coil.

the coil connection sizes.

Note:

The valve actuators are not waterproof. Failure to

protect the valve from moisture may result in the

loss of heating control.

1. Support all field-installed piping independently from

the heating coil.

2. Use swing joints or flexible connectors adjacent to the

heating coil. (These devices will absorb the strains of

expansion and contraction.)

3. All return lines and fittings must be equal to the

diameter of the "outlet" connection on the hot water

coil.

4. Install a "Gate" type valve in the supply branch line as

close as possible to the hot water main and upstream

of any other device or takeoff.

5. Install a "Gate" type valve in the return branch lineas

close as possible to the return main and down stream

of any other device.

6. Install a strainer in the hot water supply branch as

shown in

7. Install the 3-way valve in an upright position, piped for

valve seating against the flow. Ensure that the valve’s

location lends itself to serviceability.

8. The Type "W" hot water coil used in WLHE units is self-

venting only when the tube water velocity exceeds 1.5

feet per second (fps). If the tube velocity is less than 1.5

feet per second, either:

a. Install an automatic air vent at the top of the return

header, using the tapped pipe connection;

or,

b. Vent the coil from the top of the return header down

to the return piping. At the vent connection, size the

return piping to provide sufficient water velocity.

9. Install a "Globe" type valve in the Bypass line as shown

Steam Heat Units (WSHE)

Steam heating coils are factory installed inside the heater

section of the unit. The coils are pitched, within the units,

to provide the proper condensate flow from the coil.

Important:

To maintain the designed degree of pitch for

the coil, the unit must be installed

absolutely level.

Once the unit is set into place, the steam piping and the

two way modulating valve (factory provided, field

installed) must be installed. The valve can be installed

inside the heater section or near the unit. If the valve is

installed in a remote location, use field supplied wiring to

extend the control wires from the heater section to the

valve. Two access holes are provided in the unit base as

shown in

Following the guidelines listed below will enhance both

the installation and operation of the "wet heat" system.

illustrates the recommended piping

configurations for the steam coil.

list the

coil connection sizes.

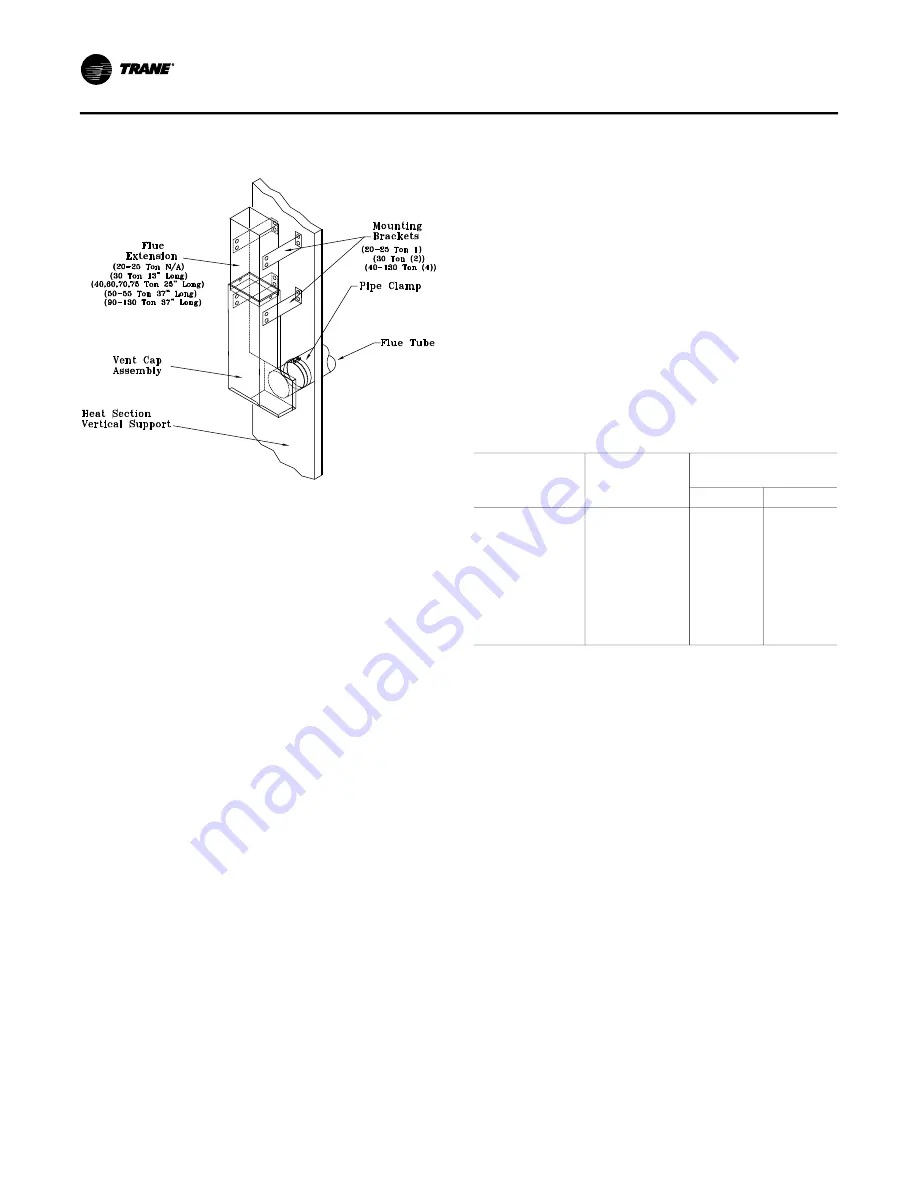

Figure 21. Flu assembly

Table 10. Connection sizes for hot water & steam coil

(a)

(a) Type W coils—with center offset headers—are used in WLHE units; Type

NS coils are used in WSHE units.

Unit Model and

Size

Heat Section

Capacity

(b)

“Model Number Descriptions,” p. 5

heating capacity.

Coil Connections

(diameter in inches)

Supply

Return

WLHE (20 - 130)

Casing 2 - 9

High or Low Heat

2-1/2”

2-1/2”

WSHE (20 - 30)

Casings 2 & 3

High or Low Heat

3”

1-1/4”

WSHE (90-130)

Casing 9

Low Heat

1-1/2”

1”

WSHE (40 - 75)

Casings 4, 5 & 6

(c)

(c) WSHE - 40 thru 130 Ton units have multiple headers

High Heat

3”

1-1/2”

Low Heat

1-1/2”

1”

Summary of Contents for IntelliPak WEHE Series

Page 15: ...General Information RT SVX35H EN 15 Figure 1 Unit component layout and ship with locations...

Page 17: ...Installation RT SVX35H EN 17 Figure 2 Typical control module location...

Page 44: ...Installation 44 RT SVX35H EN Figure 27 Typical field power wiring for W_HE casings 2 through 6...

Page 56: ...Installation 56 RT SVX35H EN Figure 32 Wiring notes for CV controls...

Page 60: ...Installation 60 RT SVX35H EN Figure 35 Wiring notes VAV...

Page 68: ...System Start up 68 RT SVX35H EN Figure 38 Typical fenwall ignition control system...

Page 69: ...System Start up RT SVX35H EN 69 Figure 39 Typical Fenwall ignition control system...