Installation

RT-SVX35H-EN

41

Chilled Water Units

Chilled water coils are factory installed inside the cooling

section of the unit. Once the unit is set into place, the

chilled water piping and the appropriate modulating valve

(factory provided, field installed) must be installed. Two

access holes are provided in the unit base as shown in

. Chilled Water coil inlet and

outlet connections are 2 1/2 inch male NPT.

Support all field-installed piping independently from the

chilled water coil.

Important:

The valve actuators are not waterproof.

Failure to protect the valve from moisture

may result in the loss of cooling control.

When applying air handlers with a chiller water coil and an

economizer, the coil should be completely drained for

winter operation. If the coil can not be completely drained,

the coil should be filled with a glycol mixture that will

protect the solution from freezing to design winter

ambient temperatures.

Disconnect Switch External Handle

(Factory Mounted Option)

Units ordered with the factory mounted disconnect switch

comes equipped with an externally mounted handle. This

allows the operator to disconnect power from the unit

without having to open the control panel door. The handle

locations and its three positions are shown below;

"ON" - Indicates that the disconnect switch is closed,

allowing the main power supply to be applied at the unit.

"OFF" - Indicates that the disconnect switch is open,

interrupting the main power supply to the unit controls.

"OPEN COVER/RESET" - Turning the handle to this position

releases the handle form the disconnect switch, allowing

the control panel door to be opened.

Once the door has been opened, it can be closed with the

handle in any one of the three positions outlined above,

provided it matches the disconnect switch position.

The handle can be locked in the "OFF" position. While

holding the handle in the "OFF" position, push the spring

loaded thumb key, attached to the handle, into the base

slot. Place the lock shackle between the handle and the

thumb key. This will prevent it from springing out of

position.

An overall layout of the field required power wiring is

illustrated in

. To insure that the unit's

supply power wiring is properly sized and installed, follow

the guidelines outlined below.

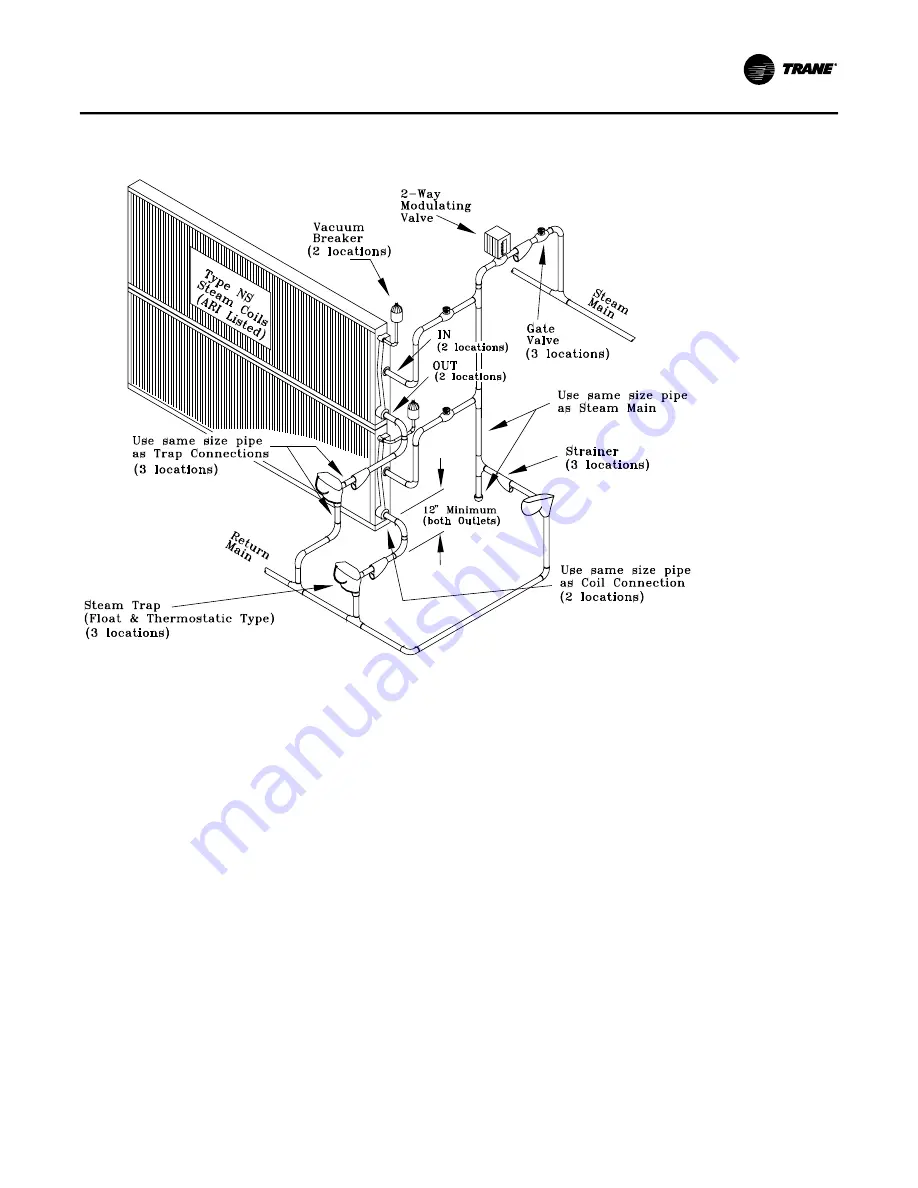

Figure 25. Steam coil piping configuration for W_HE casings 4, 5, 6 and 9

Summary of Contents for IntelliPak WEHE Series

Page 15: ...General Information RT SVX35H EN 15 Figure 1 Unit component layout and ship with locations...

Page 17: ...Installation RT SVX35H EN 17 Figure 2 Typical control module location...

Page 44: ...Installation 44 RT SVX35H EN Figure 27 Typical field power wiring for W_HE casings 2 through 6...

Page 56: ...Installation 56 RT SVX35H EN Figure 32 Wiring notes for CV controls...

Page 60: ...Installation 60 RT SVX35H EN Figure 35 Wiring notes VAV...

Page 68: ...System Start up 68 RT SVX35H EN Figure 38 Typical fenwall ignition control system...

Page 69: ...System Start up RT SVX35H EN 69 Figure 39 Typical Fenwall ignition control system...