32

18-CE07D1-1C-EN

Return Air Filters

TYPICAL AIR FILTER INSTALLATIONS

Filters are not factory supplied for furnaces. Filter size needed will be

dependent on type of filter and CFM requirement. Filters must be

installed externally to the unit.

Important:

It is recommended to transition return ducting to the

same size as the opening. It is acceptable for return duct

or filter frame to extend forward of the opening but

plastic plugs MUST be installed in any opening that the

duct or filter frame may cover.

Return Air Filters

Furnace Width

Bottom Return Filter

Qty and Size

17–1/2”

1 — 16” x 25” x 1”

Note:

For upflow airflow furnaces where the airflow requirement

exceeds 1600 CFM - Furnaces will require return air

openings and filters on: (1) both sides, or (2) one side and

the bottom, or (3) just on the bottom.

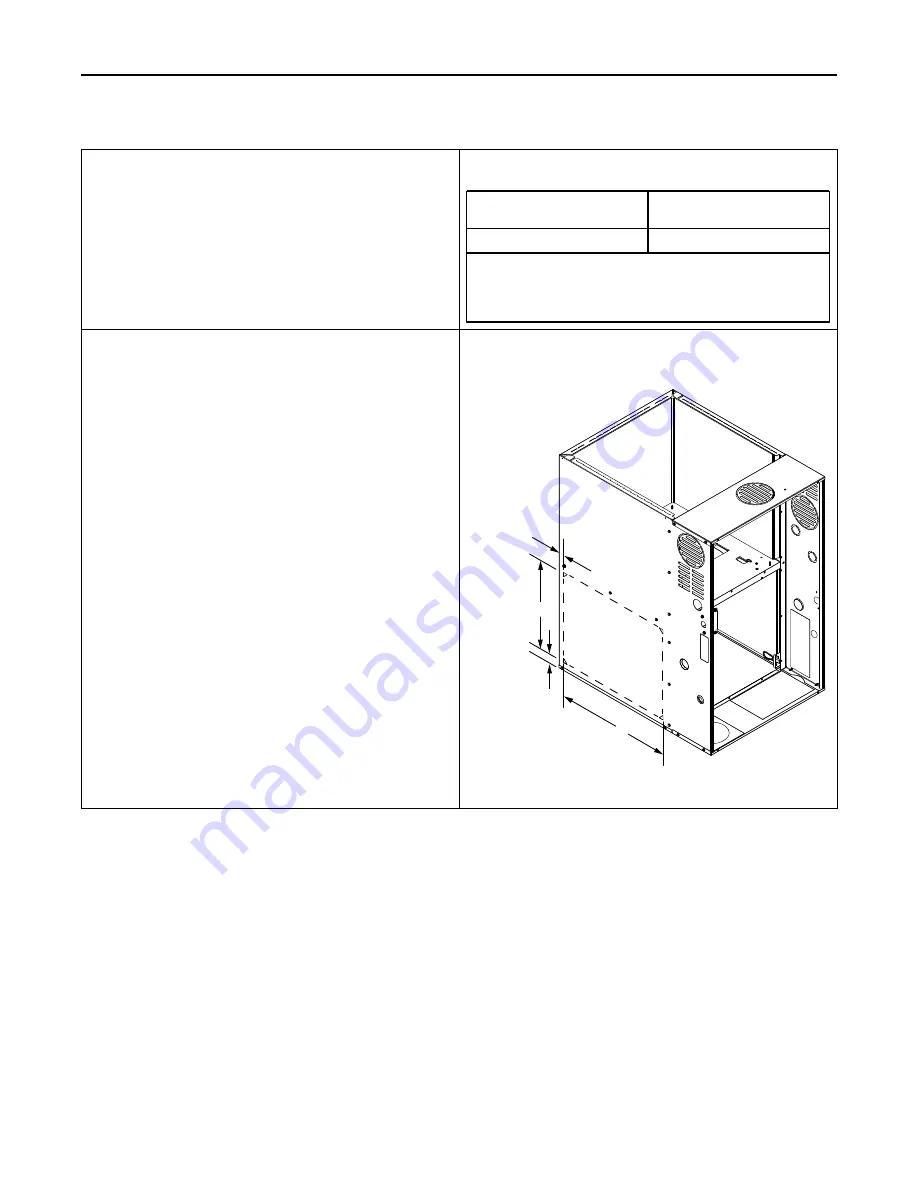

Preparation for Upflow Bottom and Side Return Air Filter

Installations

All return air duct systems should provide for installation of return air

filters.

1.

Determine the appropriate position to set the furnace in order to

connect to existing supply and return ductwork.

2.

For upflow side return installations, remove the insulation around

the opening in the blower compartment

3.

The side panels of the upflow furnace include locating notches

that are used as guides for cutting an opening for return air, refer

to the figure and the upflow furnace outline drawing for duct

connection dimensions for various furnaces.

4.

If a 3/4" flange is to be used for attaching the air inlet duct, add to

cut where indicated by dotted lines. Cut corners diagonally and

bend outward to form flange.

5.

If flanges are not required, and a filter frame is installed, cut

between locating notches as in illustration.

6.

The bottom panel of the upflow furnace must be removed for

bottom return air.

*

*

*

*

UPFLOW FURNACES ONLY

LOCATING

NOTCHES

PROVIDED

FOR SIDE

RETURN

CUTOUT

* SEE OUTLINE DRAWING

FRONT OF

FURNACE