Operating Procedures

40

ARTC-SVX002A-EN

A 10% to 50% solution of glycol should be added to

prevent pipe corrosion regardless of the fluid temperature.

Propylene glycol has corrosion inhibitors that protect

piping and components from corrosion and buildup of rust

and other deposits. Trane recommends against using

water/glycol solution in excess of 50% regardless of the

ambient temperature conditions.

Note:

If glycol-free solutions are mandated at the chiller

site, special inhibitors are available for rust

prevention, mineral deposit inhibition, and

biological suppression. Adding these inhibitors to

the water solution is strongly recommended.

Heaters, heat tracing cable, and closed cell insulation can

be installed on any exposed “wet” chiller components and

tank and pump modules for protection against freezing in

low ambient temperature and low refrigerant pressure

conditions. However, the best freeze prevention is using

the appropriate concentration of glycol. Trane does not

warranty any component that fails due to freezing.

Prevent Freezing

Many liquids expand in volume upon cooling. This

expansion may cause pipes and other enclosed systems

containing a liquid to rupture or burst when exposed to

low temperature conditions. Burst protection is needed to

protect piping and other enclosed systems when they are

inactive as they could rupture due to expansion during

cold weather or low refrigerant pressure.

Freeze points and burst points of glycol-water solutions

are shown in

In order to maintain a high quality glycol solution, the

water used in the glycol mixture must have very few

impurities. Impurities in the water can increase metal

corrosion, aggravate pitting of cast iron and steel, reduce

the effectiveness of the corrosion inhibitors, and increase

the depletion rate of the inhibitor package.

To assure inhibitor effectiveness, the levels of chlorides

and sulfates in the water should not exceed 25 ppm each.

The total hardness in terms of calcium carbonate should

be less than 100 ppm. For best long-term results, de-

ionized or distilled water is recommended. Trane can

provide concentrated solutions of Dowfrost, propylene

glycol, or premixed solutions for use with the chiller.

Propylene Glycol

Glycol-based fluids provide such burst protection in water

solutions due to their low freezing points. As a glycol-

based fluid cools below the solution’s freezing point, ice

crystals begin to form, and the remaining solution

becomes more concentrated in glycol. This ice/water/

glycol mixture results in a flowable slush, and remains

fluid, even as the temperature continues to cool.

The fluid volume increases as this slush forms and the

temperature cools, flowing into available expansion

volume in the chiller. If the concentration of glycol is

sufficient, no damage to the chiller from fluid expansion

should occur within the temperature range indicated in

. When liquids are cooled they eventually

either crystallize like ice or become increasingly viscous

until they fail to flow and set up like glass. The first type of

behavior represents true freezing. The second is known as

super-cooling. Glycols do not have sharp freezing points.

Under normal conditions, propylene glycol sets to a glass-

like solid, rather than freezing.

The addition of glycol to water yields a solution with a

freezing point below that of water. This has led to the

extensive use of glycol-water solutions as cooling media

at temperatures appreciably below the freezing point of

water. Instead of having sharp freezing points, glycol-

Table 7.

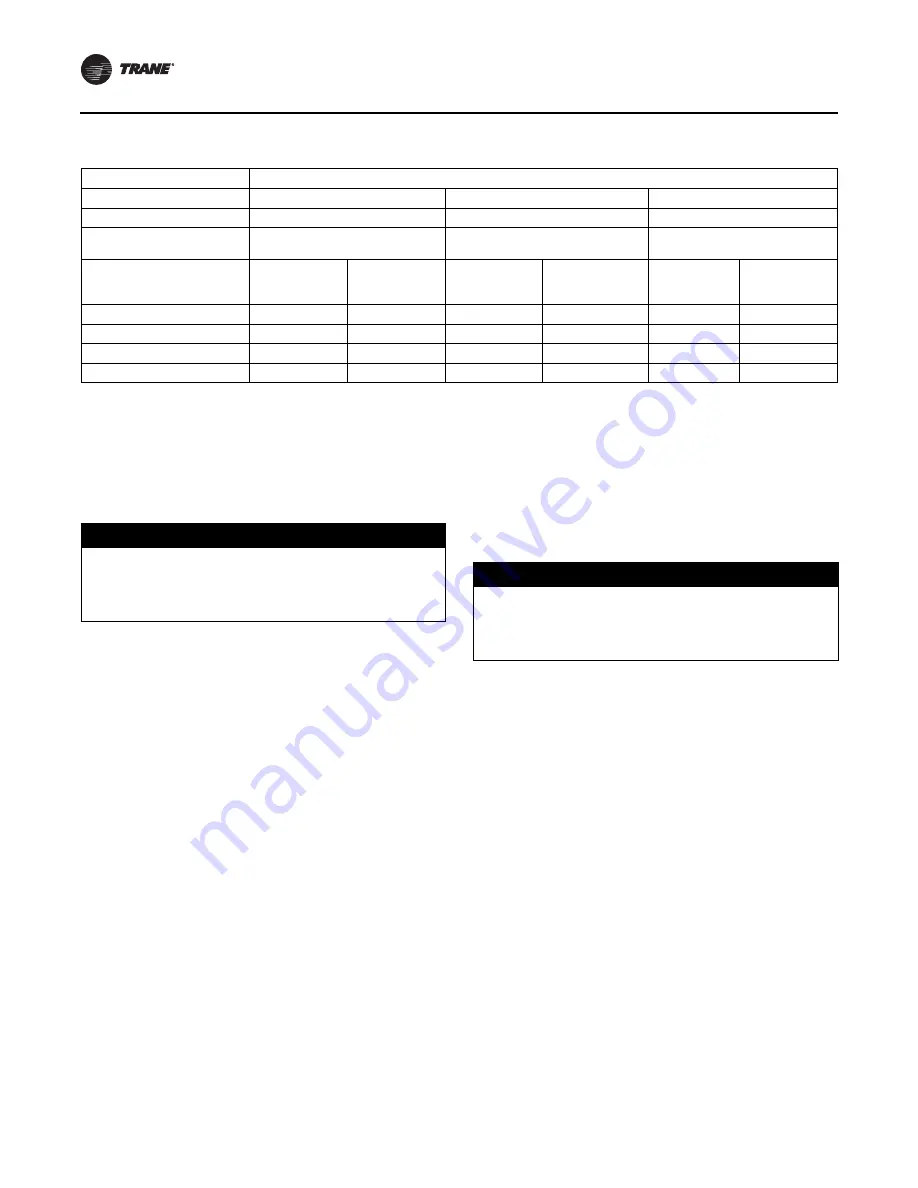

Glycol performance impact factors

Range Factor

Glycol Concentration Percentages and Performance Impact

Propylene Glycol Concentration

30%

40%

50%

Lowest Ambient Temperature

10 °F (-12 °C)

-4 °F (-10 °C)

-20 °F (-29 °C)

Recommended Minimum

Leaving Fluid Temperature

25 °F (-4 °C)

10 °F (-12 °C)

-10 °F (-23 °C)

Leaving Temperature

Capacity

Reduction

Factor

Pressure Drop

Factor

Capacity

Reduction

Factor

Pressure Drop

Factor

Capacity

Reduction

Factor

Pressure Drop

Factor

70 °F (21 °C)

0.96

1.27

0.93

1.43

0.91

1.63

60 °F (15.6 °C)

0.95

1.31

0.92

1.47

0.90

1.68

55 °F (13 °C)

0.95

1.31

0.92

1.50

0.89

1.73

50 °F (10 °C)

0.94

1.33

0.91

1.51

0.88

1.75

NOTICE

Equipment Damage!

Failure to follow instructions below could result in

permanent damage to pump and internal cooling

surfaces. Do not use automotive antifreeze.

NOTICE

Equipment Damage!

Failure to follow instructions below could result in

permanent damage to pump and internal cooling

surfaces. Do not use automotive antifreeze.