ARTC-SVX002A-EN

49

Maintenance Procedures

Maintenance Strategy

The primary goal of preventive maintenance is to avoid

the consequences of failure of equipment. This may be by

preventing the failure before it actually occurs which

preventive maintenance helps to achieve. It is designed to

preserve and restore equipment reliability by replacing

worn components before they actually fail. In addition,

operators can record equipment operating conditions,

temperatures, and pressures so they know to replace or

repair worn parts before they cause chiller failure. The

ideal maintenance program predicts and prevents

unnecessary and costly repairs and chiller down time.

Trane chillers are designed for ease of access with a

premium placed on locating key components to facilitate

visual inspection and hands-on verification.

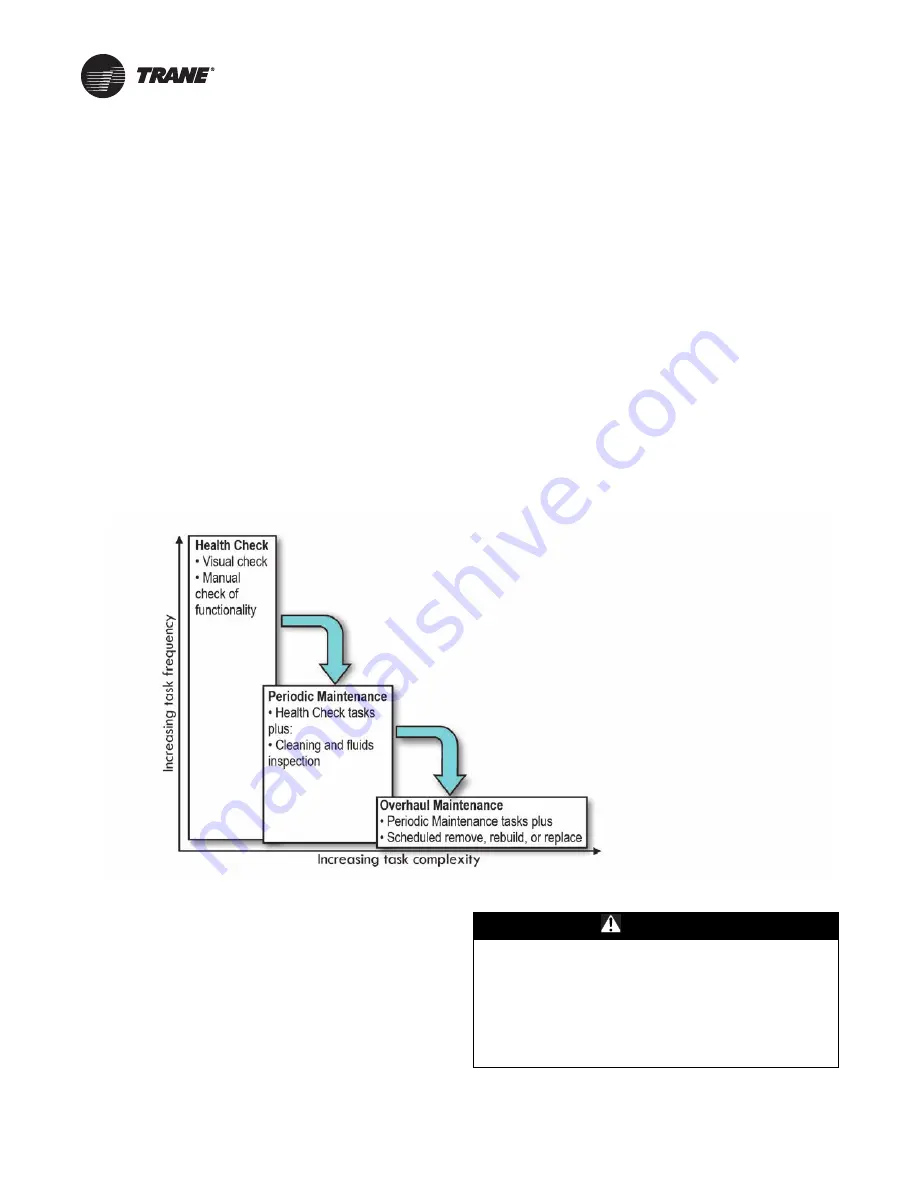

One approach to chiller maintenance envisions three

levels of maintenance effort reflecting frequent, periodic,

and scheduled maintenance tasks, with each level building

on the previous level. A daily or weekly “health check”

involves habitual visual and manual inspections of the

components of the chiller so that anomalies become

evident when they occur. Weekly or monthly periodic

maintenance involves cleaning specific components and

inspecting glycol and lubrication fluids. Finally, since all

components will eventually wear out, a prudent

maintenance strategy will anticipate and schedule

replacement or rebuilding of critical components before

they fail and require emergency response to keep chillers

operational. See below figure.

Maintenance for HVAC equipment and facilities can

include a “preventive maintenance checklist” which

includes small checks which can significantly extend

service life. Other considerations such as weather and

equipment age are taken into account; maintenance and

equipment replacement is often performed before the

hottest time of the year.

Power Disconnect Switch

Some Manhattan™ Gen II Chiller units are optionally

equipped with a panel-mounted disconnect switch

installed on the outside of the power distribution panel (or

on each module’s electrical and control panel if the chiller

has power supplied to each individual module). The

disconnect switch must be turned to the OFF position

before the panel can be opened for service. When the

panel door is open, power can be reconnected by turning

the handle located on the inside of the panel to the ON

position.

Figure 24.

An approach to chiller maintenance

WARNING

PPE for Arc/Flash Required!

Failure to wear appropriate PPE could result in death or

serious injury.

To avoid being injured, technicians MUST put on all

necessary Personal Protective Equipment (PPE), in

accordance with NFPA70E for arc/flash protection,

PRIOR to entering the panel.