28

200

220

240

260

280

300

320

340

360

380

400

420

440

460

480

500

520

540

560

580

600

75

80

85

90

95

100

105

110

115

120

125

130

135

Liquid Pressure (psig)

Liquid Temperature (F)

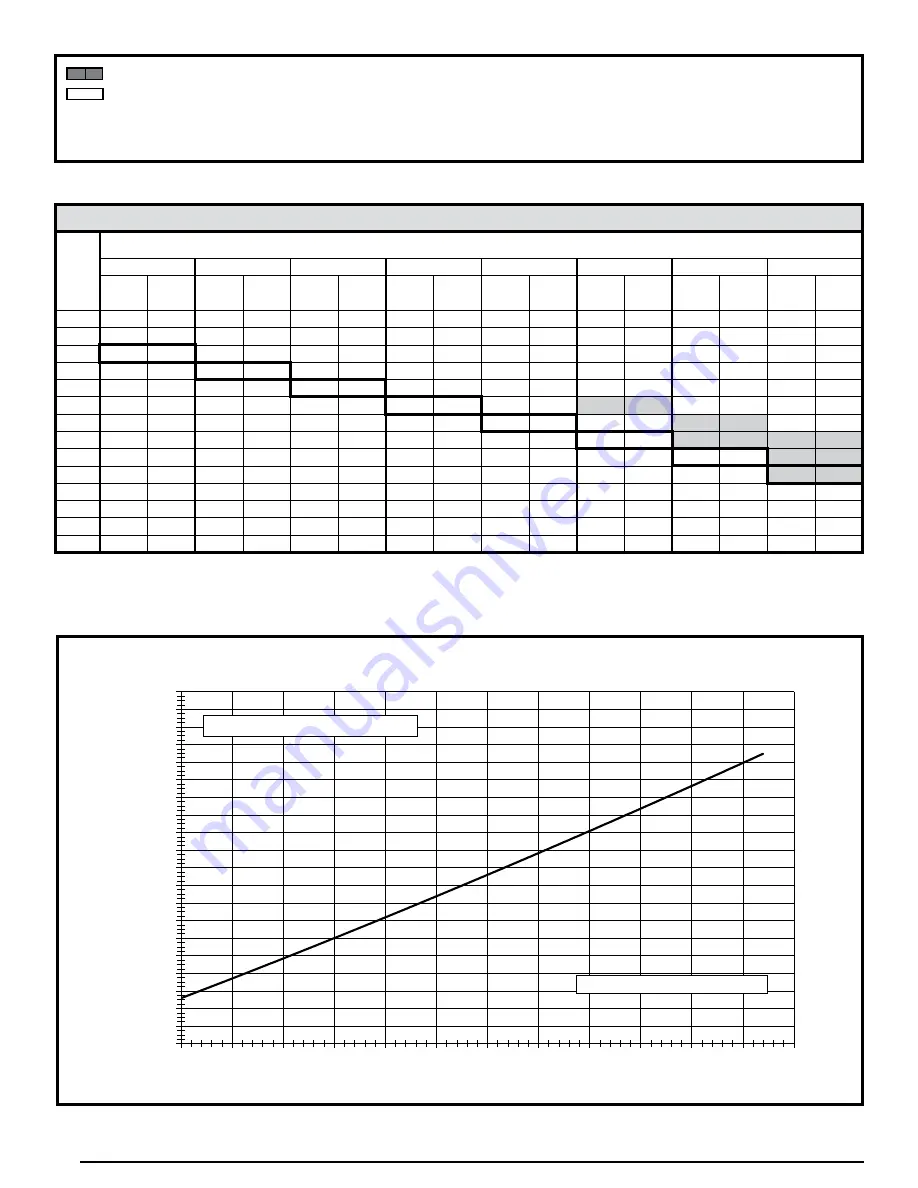

5 Ton Charging Chart - Cooling

Add refrigerant when below curve

Remove refrigerant when above curve

Figure 13. Charging Chart for 5 Ton Models

048K SERIES

SUCT.

PRESS.

OUTDOOR TEMPERATURE (°F)

70

75

80

85

90

95

100

105

LIQ.

PRESS.

DIS.

TEMP.

LIQ.

PRESS.

DIS.

TEMP.

LIQ.

PRESS.

DIS.

TEMP.

LIQ.

PRESS.

DIS.

TEMP.

LIQ.

PRESS.

DIS.

TEMP.

LIQ.

PRESS.

DIS.

TEMP.

LIQ.

PRESS.

DIS.

TEMP.

LIQ.

PRESS.

DIS.

TEMP.

127

248

130

129

250

135

273

134

131

252

140

275

139

298

139

133

257

141

277

144

300

144

323

144

135

260

143

282

146

303

148

326

148

349

148

137

285

149

307

151

328

153

351

153

374

153

139

310

155

332

156

353

157

376

157

399

158

141

335

160

356

161

378

162

401

162

424

163

143

338

163

360

165

381

166

403

166

426

167

145

363

169

385

170

406

170

428

170

147

388

174

410

174

431

175

149

413

179

435

179

151

438

184

153

Table 14. Charging Table for 4 Ton Models

Shaded boxes indicate flooded conditions.

Rated design values. The suction pressure will be lower than design value if indoor air flow, entering dry bulb, or

entering wet bulb temperatures are lower than design.

1. All pressures are listed in psig and all temperatures in ° F

2. Discharge temperatures greater than charted values indicate an undercharged system.