Carefully unpack the unit and inspect the contents for damage. If

any damage is found at the time of delivery, proper notification and

claims should be made with the carrier.

Check the rating plate to assure model number and voltage.

Furthermore, check that kits match with what was ordered. The

manufacturer should be notified within 5 days of any discrepancy or

parts shortage.

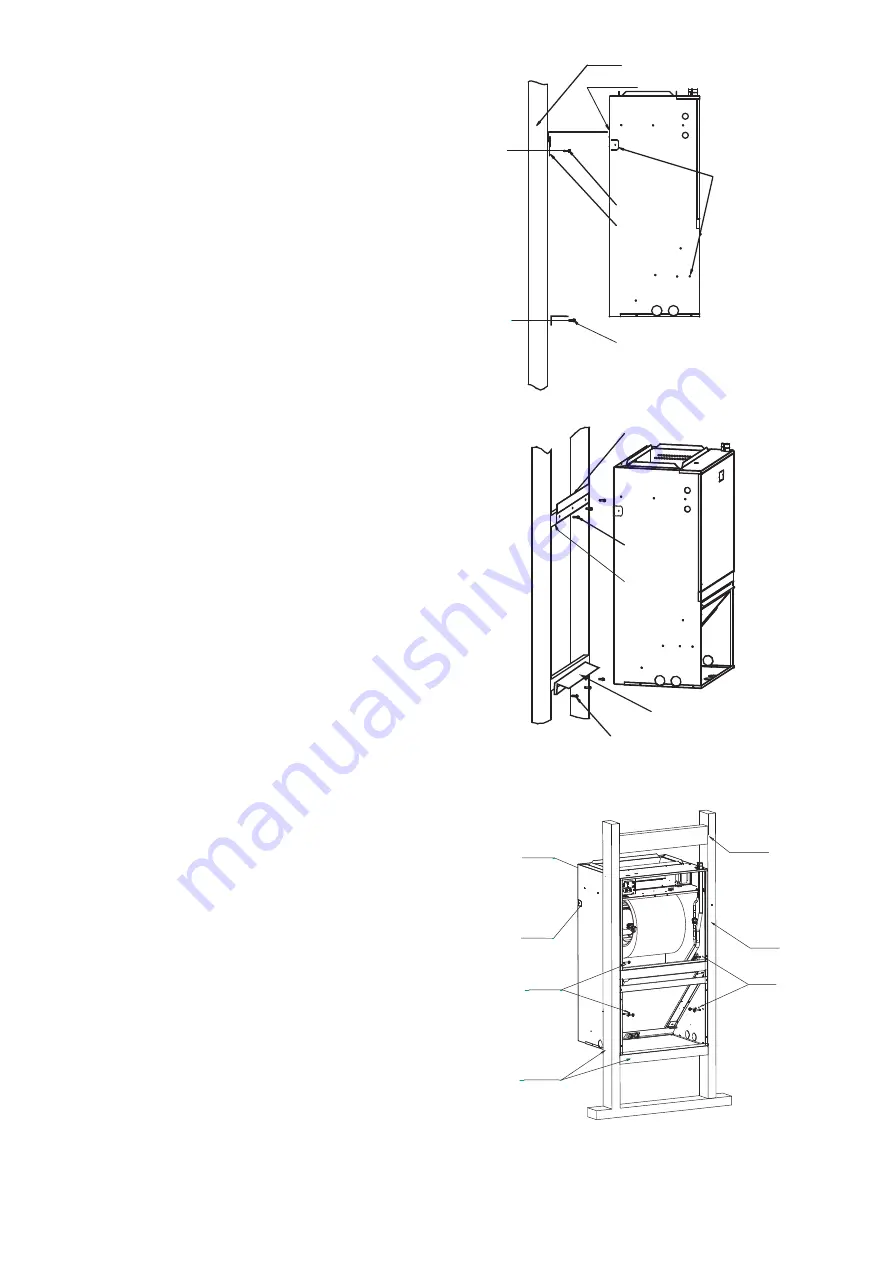

The small air handler should be centrally located and may be

installed in a closet, alcove, utility room, or basement. Minimum

clearances must be met.

The air handler comes standard with two different options for

mounting, wall mount or frame mount. Both mounting options require

the unit to be level from side to side and from front to back in order to

allow condensate to properly drain from the unit. Failure to do this will

result in condensate leaking out from the unit, potentially causing

structural damage to the surrounding support structures, dry wall,

carpet, etc. Also, both mounting structures require the ability to

accommodate a minimum of 150 lb load. Failure to do this will cause

damage to the support structure and potentially damage the unit.

The

air

handler

comes

standard

with

an

upper

and lower wall mount

bracket. Reference Figure 3-1 for more detail.

1.

Remove

lower

wall

mounting

bracket

from

the

back

of

the

unit

by

removing

one

screw

which

attaches

the

bracket

to

the

air

handler.

Note:

Discard the screw after you have removed the wall mounting

bracket.

2.

Install

bracket

on

the

wall

by

using

3

wood

screws

(not

provided).

Make

sure

the

bracket

is

level

in

order

to

provided

proper

drainage

from

the

unit.

Note:

Do

not

attach

the

wall

mounting

bracket

into

unsupported

dry

wall.

Make

sure

that

the

wood

screws

are going into

a structure that can suppport a minimum load of 150 lb.

3.

Lift

the

air

handler

above

the

wall

mounting

bracket and attach the

unit to the installed bracket. Reference Figure 3-1.

4.

Install

the

additional

bottom plate for extra support for this type

mounting (see figure 3-1).

Note:

The

additional

plate

is shipped in the bottom of the shipping

carton (only for 30/36k unit).

3.2.1 WALL MOUNT

Fig. 3-2 FRAME MOUNT

The

air

handler

comes

with

8

clearance

holes

(4

on

each

side).

These

holes

are

used

to

mount

the

air

handler

inside

of

a

frame

structure

(see

Figure

3-2).

When

mounting

in

this

fashion,

make

sure

that

the

wood

screws

are

mounted

from

within

the

air

handler

and

not

outside

of

the

unit.

Install

the

screws

from

outside

the

unit,

and

avoid

damaging

the

coil.

If

the

frame

does

not

provide

support

in

the

front

of

the

unit

and

additional

support

is

needed,

open

up

the

tabs

and

fix

the

unit

to

the

frame

or

other

support

structure

with

screws

(only

for

30K/36K).

Select

a

solid

and

level

site

to

ensure

proper

installation

of

the

frame

mount.

Verify

that

there

is

sufficient space for installation

and maintenance.(See Figure. 3-3)

3.2.2 FRAME MOUNT

Fig. 3-1 WALL MOUNT

Section 3. Installation Instructions

3.1 Unpacking

3.2 Location

WALL STRUTURE

WOOD SCREWS

WOOD SCREWS

PROVIDED WALL

MOUNT BRACKET

NOTE: MOUNTING WALL AND SUPPORTING

STRUCTURE MUST BE ABLE TO SUPPORT A

MINIMUM OF 150 LBS.

PROVIDED AIR HANDLER

MOUNTING BRACKET

NOTE:

IN ORDER TO PREVENT

AIR LEAKAGE,THE TABS

AND SCREW HOLES

NEED TO BE SEALED

UP WHEN THEY ARE

NOT TO BE USED

PROVIDED WALL

MOUNT BRACKET

WOOD SCREWS

SUPPORTING 2

"

X4

"

STRUCTURE

WOOD SCREWS

WALLMOUNT BRACKET

(ONLY FOR 30K/36K)

WALL STRUCTURE

SUPPORTING

2˝X4˝ STRUCTURE

WOOD SCREWS

SUPPORTING

2˝X4˝ STRUCTURE

STUD ATTACHMENT

HOLES

THE TABS

BRACKET PLACEMENT FOR

HANGING IN A CLOSET

damage. See Figure 3-2 for frame mount installation.

studs. If they are not used, the unit may fall down or cause other

on a wood frame, the screws should be used to fix the unit to the

wood screws are recommended. When the unit is installed

˝

#12 x 1 ½

The (8) wood screws are not provided with the unit.

IMPORTANT:

4