Figure 5.

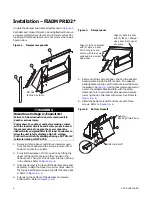

Reinstall end panel

Installation – FIADMPR103*

10

ACC-SVN231A-EN

Factory Installed Damper (Field

Set-Up)

Downflow Configuration

To position damper for downflow operation, complete the

following steps:

WARNING

Hazardous Voltage!

Failure to disconnect power before servicing could

result in death or serious injury.

Disconnect all electric power, including remote

disconnects before servicing. Follow proper lockout/

tagout procedures to ensure the power can not be

inadvertently energized. Verify that no power is

present with a voltmeter.

1. Remove filter access panel.

2. Remove the lower screws in the end panel. See

. Lay blockoff angle aside for later

installation.

Figure 6.

Remove lower screws

3. Do not remove the screws in the upper row of the end

panel.

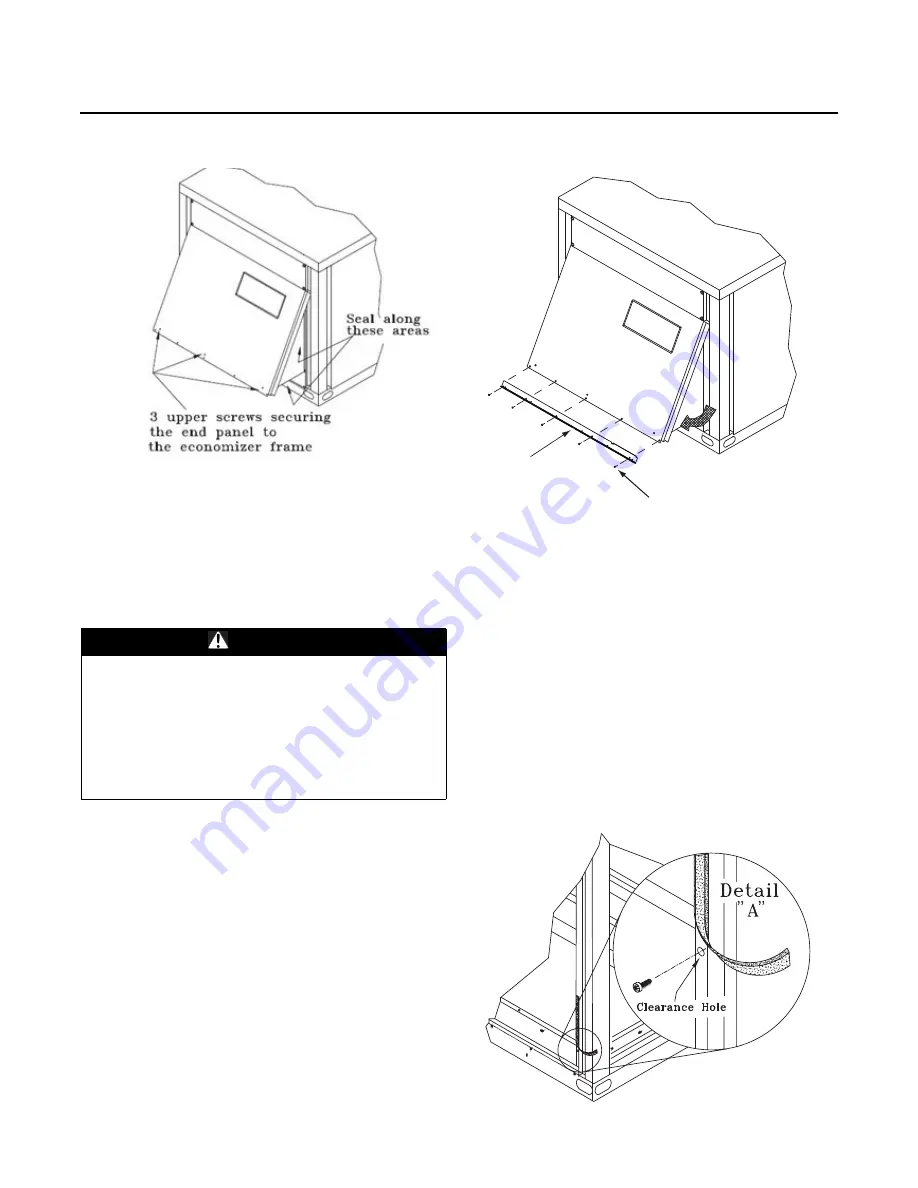

4. Grasp the bottom of the end panel and pull the

economizer assembly outward into the operating

position. See

.

5. Remove approximately 3-inches of gasket material

from the bottom of each corner post to expose the

holes used to attach the economizer assembly to the

unit. See

.

6. With the screws provided, secure each side of the

economizer assembly by inserting a screw through the

clearance hole in the bottom of the corner post and into

the engagement hole in the economizer assembly.

Refer to

.

Figure 7.

Remove gasket material

Remove screws and lay blockoff

angle aside. Do not discard.

Blockoff Angle

Summary of Contents for Precedent FIADMPR102 Series

Page 14: ...Notes 14 ACC SVN231A EN...

Page 15: ...Notes ACC SVN231A EN 15...