134

RTAA-IOM-3

[ ] If operating pressures and sight

glass conditions seem to indicate

refrigerant shortage, measure the

system superheat and system

subcooling. Refer to “System

Superheat” and “System

Subcooling”.

[ ] If operating conditions indicate a

refrigerant overcharge, remove

refrigerant at the liquid line service

valve. Allow refrigerant to escape

slowly, to minimize oil loss. Do not

discharge refrigerant into the

atmosphere.

WARNING: Do not allow

refrigerant to directly contact

skin or injury from frostbite may

result.

[ ] Inspect the entire system for

unusual conditions and inspect the

condenser coils for dirt and debris. If

the coils are dirty, refer to “Coil

Cleaning”.

Monthly Maintenance

[ ] Perform all weekly maintenance

procedures.

[ ] Measure and record the system

superheat. Refer to “System

Superheat”.

[ ] Measure and record the system

subcooling. Refer to “System

Subcooling”.

[ ] Manually rotate condenser fans to

insure proper clearance on the fan

openings.

WARNING: Position all electrical

disconnects in the “OPEN”

position and lock them, to

prevent injury or death due to

electrical shock.

Annual Maintenance

[ ] Perform all weekly and monthly

maintenance procedures.

[ ] Check the oil level and refrigerant

charge. Refer to “Maintenance

Procedures”.

[ ] Have a qualified laboratory perform

a compressor oil analysis to

determine system moisture content

and acid level. This analysis is a

valuable diagnostic tool.

[ ] Contact a qualified service

organization to leak test the chiller,

to check operating and safety

controls, and to inspect electrical

components for deficiencies.

[ ] Inspect all piping components for

leakage and damage. Clean out any

inline strainers.

[ ] Clean and repaint any areas that

show signs of corrosion.

[ ] Clean the condenser coils. Refer to

“Coil Cleaning”.

[ ] Clean the Domestic Water Heater.

Refer to Domestic Water Heater tube

cleaning procedure.

WARNING: Position all electrical

disconnects in the “OPEN”

position and lock them, to

prevent injury or death due to

electrical shock.

[ ] Clean the condenser fans. Check the

fan assemblies for proper clearance

in the fan openings and for motor

shaft misalignment, abnormal

endplay, vibration and noise.

WARNING: Position all electrical

disconnects in the “OPEN”

position and lock them, to

prevent injury or death due to

electrical shock.

Summary of Contents for RTAA-130

Page 2: ... American Standard Inc 1991 ...

Page 8: ...8 RTAA IOM 3 ...

Page 24: ...24 RTAA IOM 3 ...

Page 50: ...50 RTAA IOM 3 Figure 30 Refrigerant Circuit Identification ...

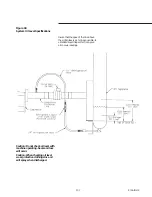

Page 52: ...52 RTAA IOM 3 Figure 31 Remote Evaporator Piping Example ...

Page 59: ...59 RTAA IOM 3 Continued from Previous Page See Notes on Next Page ...

Page 63: ...63 RTAA IOM 3 Continued from Previous Page See Notes on Page 61 ...

Page 65: ...65 RTAA IOM 3 Continued from Previous Page See Notes on Page 61 ...

Page 76: ...76 RTAA IOM 3 ...

Page 92: ...92 RTAA IOM 3 Figure 51 Operator Interface Controls ...

Page 120: ...120 RTAA IOM 3 ...

Page 127: ...127 RTAA IOM 3 Continued from Previous Page 2307 1566C ...

Page 128: ...128 RTAA IOM 3 Figure 57 Unit Sequence of Operation RTAA 130 to 200 Tons 2306 9122A ...

Page 132: ...132 RTAA IOM 3 Figure 58 Operator s Log ...

Page 138: ...138 RTAA IOM 3 ...