41

RTAA-IOM-3

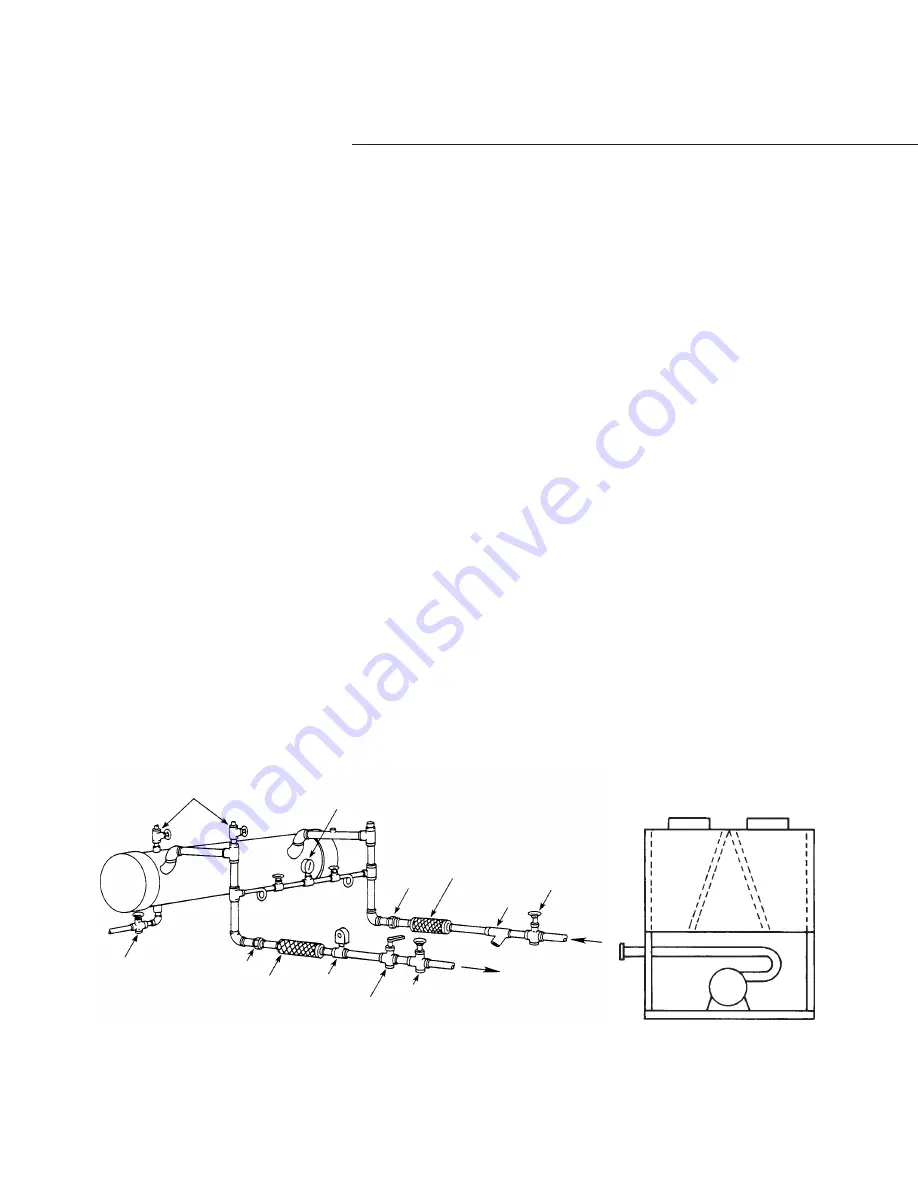

Evaporator Piping

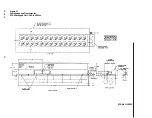

Figure 22 illustrates typical evaporator

piping components. Components and

layout will vary slightly, depending on

the location of connections and the

water source.

Caution: The chilled water

connections to the evaporator are

to be “victaulic” type connections.

Do not attempt to weld these

connections, as the heat generated

from welding can cause internal

damage to the evaporator.

The chilled water connections are on

the left side of the unit. If it is necessary

for the chilled water piping to enter the

unit from the right side, elbows can be

used to route the piping 1800 over the

top of the evaporator, as shown in

Figure 22, for RTAA 130-200 units only.

A vent is provided on the top of the

evaporator at the return end. Be sure to

provide additional vents at high points

in the piping to bleed air from the

chilled water system. Install necessary

pressure gauges to monitor the

entering and leaving chilled water

pressures.

Caution: To prevent damage to

chilled water components, do not

allow evaporator pressure

(maximum working pressure) to

exceed 215 psig.

Provide shutoff valves in lines to the

gauges to isolate them from the

system when they are not in use. Use

rubber vibration eliminators to prevent

vibration transmission through the

water lines.

If desired, install thermometers in the

lines to monitor entering and leaving

water temperatures. Install a balancing

valve in the leaving water line to

control water flow balance. Install

shutoff valves on both the entering and

leaving water lines so that the

evaporator can be isolated for service.

A pipe strainer should be installed in

the entering water line to prevent

waterborne debris from entering the

evaporator.

Figure 22

Suggested Piping for

Typical RTAA Evaporator

Vents

Valved

Pressure

Gauge

Drain

Union

Vibration

Eliminator

Flow

Switch

(Optional) Balancing Valve

Gate Valve

Union

Water

Strainer

Vibration

Eliminator

Gate Valve

RTAA 130-200

with Opposite-Side Connections

(View from end opposite control panel)

Summary of Contents for RTAA-130

Page 2: ... American Standard Inc 1991 ...

Page 8: ...8 RTAA IOM 3 ...

Page 24: ...24 RTAA IOM 3 ...

Page 50: ...50 RTAA IOM 3 Figure 30 Refrigerant Circuit Identification ...

Page 52: ...52 RTAA IOM 3 Figure 31 Remote Evaporator Piping Example ...

Page 59: ...59 RTAA IOM 3 Continued from Previous Page See Notes on Next Page ...

Page 63: ...63 RTAA IOM 3 Continued from Previous Page See Notes on Page 61 ...

Page 65: ...65 RTAA IOM 3 Continued from Previous Page See Notes on Page 61 ...

Page 76: ...76 RTAA IOM 3 ...

Page 92: ...92 RTAA IOM 3 Figure 51 Operator Interface Controls ...

Page 120: ...120 RTAA IOM 3 ...

Page 127: ...127 RTAA IOM 3 Continued from Previous Page 2307 1566C ...

Page 128: ...128 RTAA IOM 3 Figure 57 Unit Sequence of Operation RTAA 130 to 200 Tons 2306 9122A ...

Page 132: ...132 RTAA IOM 3 Figure 58 Operator s Log ...

Page 138: ...138 RTAA IOM 3 ...