69

RTAA-IOM-3

Interconnecting Wiring

Chilled Water Pump Interlock

and External Auto/Stop for

Model RTAA Air-Cooled

Series R CenTraVac

Caution: The following must be

adhered to or equipment damage

may occur.

The Model RTAA Series R chiller

requires a minimum of two field-

supplied control inputs:

•

Chilled water pump interlock (TB3-1, -

2 on the 1U1 board).

•

External Auto/Stop (T133-3, -4 on the

1U1 board)

When there is a command to shut

down the chilled water system, the

chilled water pump is required to

operate for a minimum of one minute

after the External AUTO/STOP gives

the shutdown command.

Normally, when the compressors are

terminating a cycle (via chiller Stop/

Reset switch, loss of load, Low

Ambient Run Inhibit or External Auto/

Stop), the controller will initiate the

“Run:Unload” mode. This operating

mode energizes the unload solenoid

for 20 seconds, to unload the

compressor so that it will be unloaded

for the next start-up. Then the master

oil solenoid is de-energized and closure

of the master oil solenoid is verified.

The entire process may take up to 40

seconds.

If the chilled water pump interlock is

used without the external Auto/Stop

input, the chiller will shut down

immediately upon the command for

shut down, without initiating the

“Run:Unload” mode. This is

considered a “non-friendly” shut down

and a “Machine Auto Reset” diagnostic

will be displayed on the LICK

Caution: The method in the

previous paragraph is not to be

used as a normal means of cycling

the chiller off, e.g. time clock,

building automation system, etc.

The proper method for cycling the

chiller off is to open a set of contact

between TB3-3, -4 on the 1U1 board

(External Auto/Stop). Then, following a

one minute delay, the chilled water

pump is cycled off. Chilled water flow

indication should be provided between

TB3-1, -2 on the 1U1 board, e.g. water

pump motor starter auxiliaries and/or

flow switch.

The wiring for this recommendation is

shown in the furnished electrical

schematics and connection diagrams.

Relay 5DL1 is a normally-open,

instantaneous close, timed open (1

min.) time delay relay. An alternative

solution is to provide proper

programming in a building automation

system.

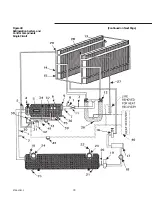

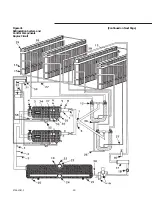

Chilled Water Pump Interlock

The installer must provide leads 520

and 521 from the chilled water pump

(5B1) starter auxiliary (5K1) to the

proper terminals of terminal strip 1U1

TB3 on the UCM, as shown in Figures

34 thru 36. Circuit requirement is 115

VAC, with minimum contact rating @

115 VAC of 6.9 VA inrush, 1.3 VA sealed.

Refer to the field diagrams which are

shipped with the unit.

The auxiliary contact of the chilled

water pump may be wired in series

with an optional flow switch, as shown.

The standard UCM provides internal

protection for the unit against loss of

chilled water flow. Also refer to

“Evaporator Flow Switch.”

External Auto/Stop Wiring

If the unit requires the Auto/Stop

function, the installer must provide

leads 522 and 523 from the remote

contacts (5K5, 5K21) to the proper

terminals of the terminal strip 1U1 TB3

on the UCM, as shown in Figures 34

thru 36.

The chiller will run normally when the

contacts are closed. When either

contact opens, the compressor(s), if

operating, will go to the RUN:UNLOAD

operating mode and cycle off. Unit

operation will be inhibited. Re-closure

of the contacts will permit the unit to

automatically return to normal

operation.

Circuit requirements are 2-wire, 115

VAC, with minimum contact rating @

115 VAC of 6.9 VA inrush, 1.3 VA sealed.

Refer to the field diagrams which are

shipped with the unit.

Summary of Contents for RTAA-130

Page 2: ... American Standard Inc 1991 ...

Page 8: ...8 RTAA IOM 3 ...

Page 24: ...24 RTAA IOM 3 ...

Page 50: ...50 RTAA IOM 3 Figure 30 Refrigerant Circuit Identification ...

Page 52: ...52 RTAA IOM 3 Figure 31 Remote Evaporator Piping Example ...

Page 59: ...59 RTAA IOM 3 Continued from Previous Page See Notes on Next Page ...

Page 63: ...63 RTAA IOM 3 Continued from Previous Page See Notes on Page 61 ...

Page 65: ...65 RTAA IOM 3 Continued from Previous Page See Notes on Page 61 ...

Page 76: ...76 RTAA IOM 3 ...

Page 92: ...92 RTAA IOM 3 Figure 51 Operator Interface Controls ...

Page 120: ...120 RTAA IOM 3 ...

Page 127: ...127 RTAA IOM 3 Continued from Previous Page 2307 1566C ...

Page 128: ...128 RTAA IOM 3 Figure 57 Unit Sequence of Operation RTAA 130 to 200 Tons 2306 9122A ...

Page 132: ...132 RTAA IOM 3 Figure 58 Operator s Log ...

Page 138: ...138 RTAA IOM 3 ...