82

RTAA-IOM-3

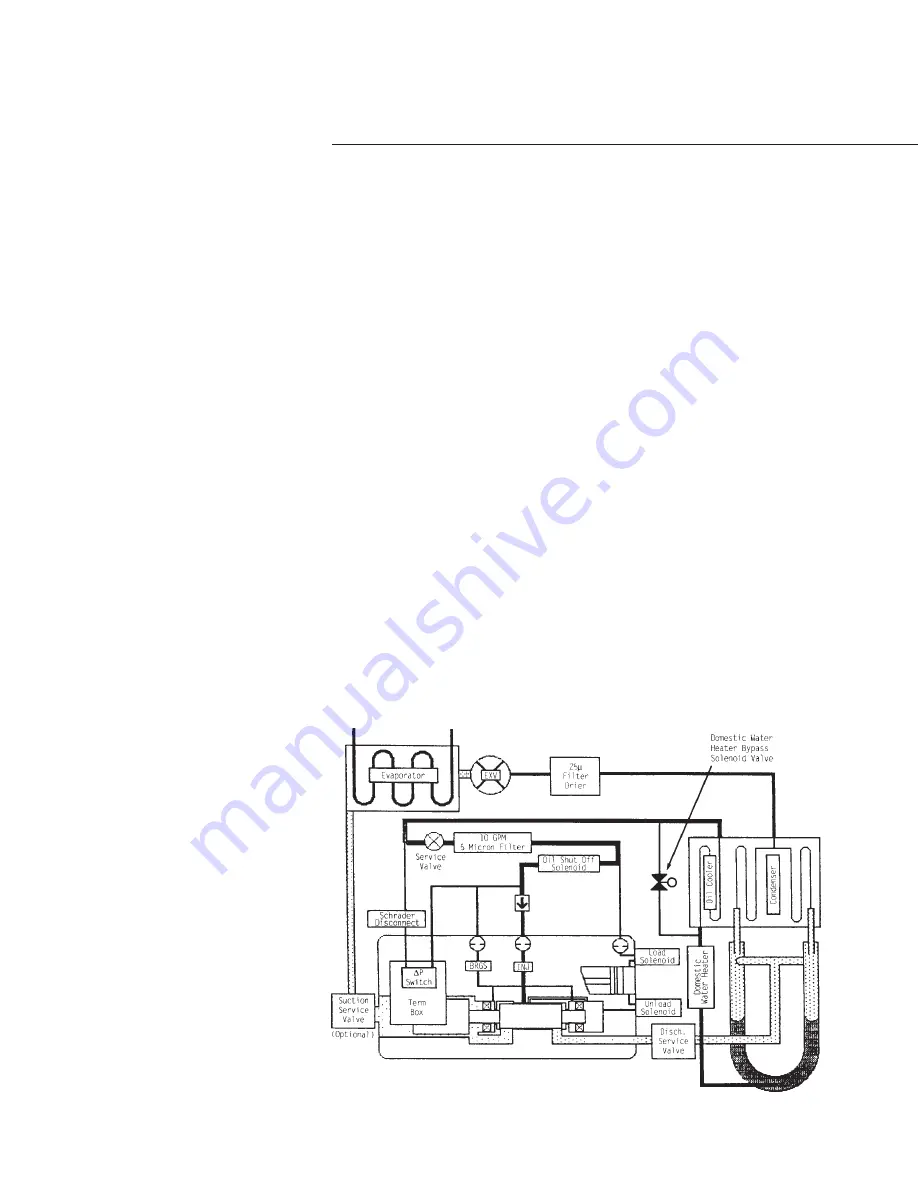

Figure 43

RTAA Compressor Oil System

Schematic

Oil System Operation

Overview

Oil that collects in the bottom of the oil

separator is at condensing pressure

during compressor operation;

therefore, oil is constantly moving to

lower pressure areas. Refer to

Figure 43.

As the oil leaves the separator, it passes

through the air-cooled oil cooler at the

top of the condensing coils. It then

goes through the service valve and

filter. At this point, some of the oil is

used to control the slide valve

movement in the compressor, via the

load/unload solenoids. The remaining

oil passes through the oil master

solenoid valve and performs the

functions of compressor bearing

lubrication and compressor oil

injection. If the compressor stops for

any reason, the master solenoid valve

closes, isolating the oil charge in the

separator and oil cooler during “off”

periods.

To ensure proper lubrication and

minimize refrigerant condensation in

the compressor, a heater is mounted

on the bottom of the compressor

housing. A signal from the UCM

energizes this heater during the

compressor “Off” cycle to keep

refrigerant from condensing in the

compressor. The heater element is

continuously energized.

Domestic Water Heater

The Domestic Water Heater option

utilizes available waste heat from the

compressor oil circuit, to heat domestic

or process water. Normally, the excess

heat is dissipated to the atmosphere by

fans moving air over the oil cooler.

The high temperature oil that leaves

the oil separator enters the domestic

water heater. Heat is transferred from

the oil to the cool water that enters the

heater. The oil then passes either

through the unit’s air-cooled oil cooler,

where additional heat is removed, if

required, or through the air-cooled oil

cooler bypass solenoid, that is

operated by a thermostat on the oil

supply line.

Water that is heated in the domestic

water heater exits the heater and flows

to the system.

Summary of Contents for RTAA-130

Page 2: ... American Standard Inc 1991 ...

Page 8: ...8 RTAA IOM 3 ...

Page 24: ...24 RTAA IOM 3 ...

Page 50: ...50 RTAA IOM 3 Figure 30 Refrigerant Circuit Identification ...

Page 52: ...52 RTAA IOM 3 Figure 31 Remote Evaporator Piping Example ...

Page 59: ...59 RTAA IOM 3 Continued from Previous Page See Notes on Next Page ...

Page 63: ...63 RTAA IOM 3 Continued from Previous Page See Notes on Page 61 ...

Page 65: ...65 RTAA IOM 3 Continued from Previous Page See Notes on Page 61 ...

Page 76: ...76 RTAA IOM 3 ...

Page 92: ...92 RTAA IOM 3 Figure 51 Operator Interface Controls ...

Page 120: ...120 RTAA IOM 3 ...

Page 127: ...127 RTAA IOM 3 Continued from Previous Page 2307 1566C ...

Page 128: ...128 RTAA IOM 3 Figure 57 Unit Sequence of Operation RTAA 130 to 200 Tons 2306 9122A ...

Page 132: ...132 RTAA IOM 3 Figure 58 Operator s Log ...

Page 138: ...138 RTAA IOM 3 ...