83

RTAA-IOM-3

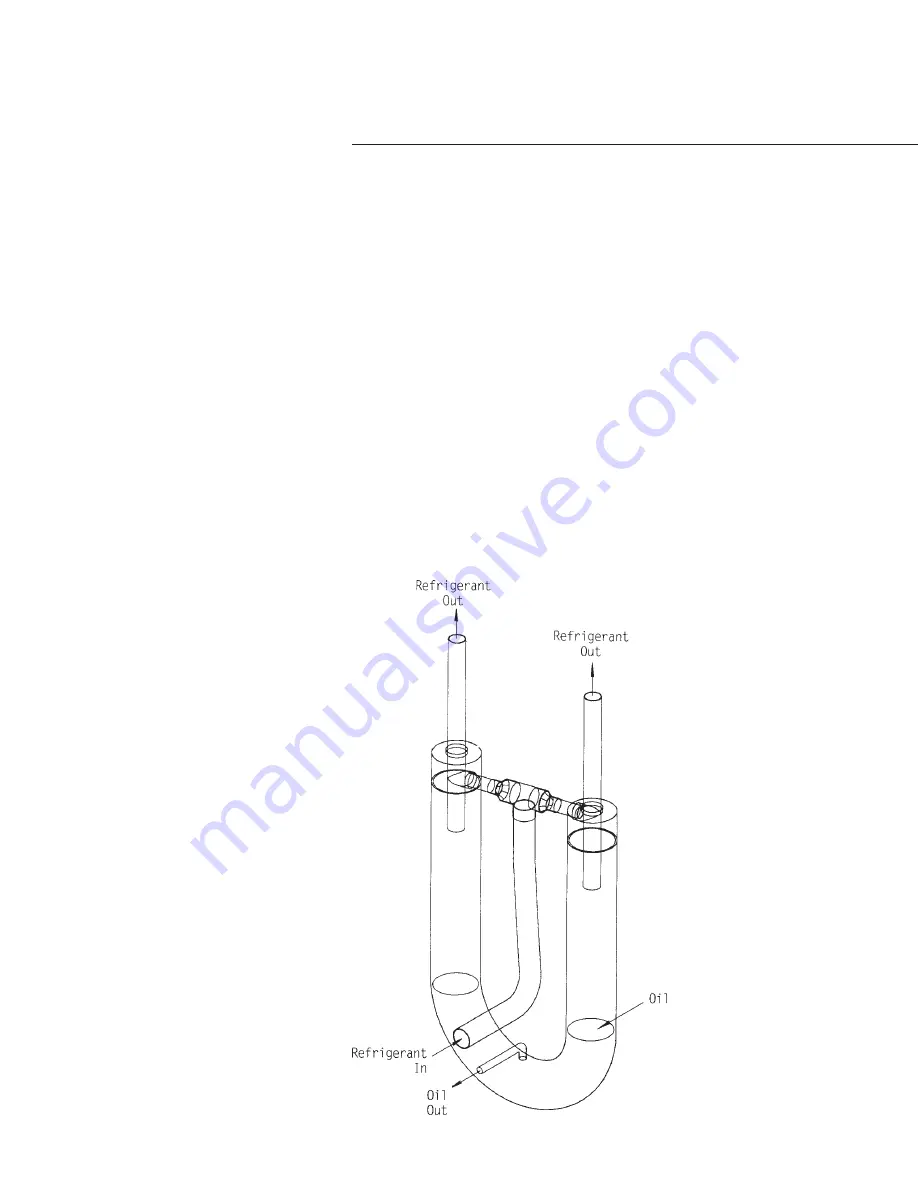

Oil Separator

The oil separator consists of a U-

shaped tube, joined at the top by the

refrigerant discharge line from the

compressor. As shown in Figure 44, the

discharge line is essentially tangential

to the U-tubes. This causes the

refrigerant to swirl in the tubes and

throws the oil to the outside, where it

collects on the walls and flows to the

bottom. The compressed refrigerant

vapor, stripped of oil droplets, exits out

the top of the oil separator and is

discharged into the condensing coils.

Compressor Bearing Oil Supply

Oil is injected into the bearing housings

located at each end of both the male

and female rotors. Each bearing

housing is vented to compressor

suction, so that oil leaving the bearings

returns through the compressor rotors

to the oil separator.

Compressor Rotor Oil Supply

Oil flows through this circuit directly

from the master solenoid valve

through the oil filter to the top of the

compressor rotor housing. There it is

injected along the top of the rotors to

seal clearance spaces between the

rotors and the compressor housing

and to lubricate the rotors.

Figure 44

Oil Separator

Summary of Contents for RTAA-130

Page 2: ... American Standard Inc 1991 ...

Page 8: ...8 RTAA IOM 3 ...

Page 24: ...24 RTAA IOM 3 ...

Page 50: ...50 RTAA IOM 3 Figure 30 Refrigerant Circuit Identification ...

Page 52: ...52 RTAA IOM 3 Figure 31 Remote Evaporator Piping Example ...

Page 59: ...59 RTAA IOM 3 Continued from Previous Page See Notes on Next Page ...

Page 63: ...63 RTAA IOM 3 Continued from Previous Page See Notes on Page 61 ...

Page 65: ...65 RTAA IOM 3 Continued from Previous Page See Notes on Page 61 ...

Page 76: ...76 RTAA IOM 3 ...

Page 92: ...92 RTAA IOM 3 Figure 51 Operator Interface Controls ...

Page 120: ...120 RTAA IOM 3 ...

Page 127: ...127 RTAA IOM 3 Continued from Previous Page 2307 1566C ...

Page 128: ...128 RTAA IOM 3 Figure 57 Unit Sequence of Operation RTAA 130 to 200 Tons 2306 9122A ...

Page 132: ...132 RTAA IOM 3 Figure 58 Operator s Log ...

Page 138: ...138 RTAA IOM 3 ...