84

RTAA-IOM-3

Slide Valve Movement

Movement of the slide valve piston

determines slide valve position which,

in turn, regulates compressor capacity.

Oil flow into and out of the cylinder

governs piston movement, and is

controlled by the normally-closed, load

and unload solenoid valves.

The solenoid valves receive

momentary pulsating “load” and

“Unload” voltage signals from the

UCM based on system cooling

requirements. To load the compressor,

the UCM opens the load solenoid valve

while keeping the unload solenoid

valve closed. The pressurized oil flow

then enters the cylinder and forces the

slide valve to move over the rotors.

The compressor is unloaded when the

load solenoid valve is kept closed and

the unload solenoid valve is opened.

Oil “trapped” within the cylinder is

drawn out into the lower-pressure

suction area of the compressor. As the

pressurized oil leaves the cylinder, the

slide valve gradually moves away from

the rotors.

When both solenoid valves are closed,

the present level of compressor loading

is maintained.

Just prior to a normal compressor

shutdown, the unload solenoid valve is

energized and the slide valve moves to

the fully-unloaded position, so the unit

always starts fully unloaded.

Oil Filter

Each refrigerant circuit is equipped with

replaceable-element oil filters. The

filter(s) remove any impurities that

could foul the solenoid valve orifices

and compressor internal oil supply

galleries. This also prevents excessive

wear of compressor rotor and bearing

surfaces. Refer to the maintenance

portion of this manual for

recommended filter element

replacement intervals.

Condenser Fans

The RTAA Series offers either the 15 F

or 0 F ambient fan configuration. On

the 0 F ambient option, the lead fan(s)

on each circuit is a half-airflow (half-

pitch blade) fan(s). Half pitch fans have

a blade pitch of 150 and full pitch fans

have a blade pitch of 27°.

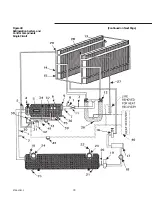

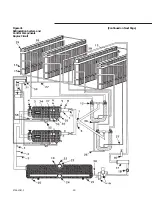

Figures 45 and 46 show the number of

fans installed on each model, the

designation of fan contactors and the

staging of fans as the UCM calls for

more condenser cooling. Fan staging is

a function of the difference between

the saturated condenser refrigerant

temperature and the saturated

evaporator refrigerant temperature,

which in turn is a function of the load

and ambient temperature. Any number

of fans can be operating at a given

time, depending on these variables.

Summary of Contents for RTAA-130

Page 2: ... American Standard Inc 1991 ...

Page 8: ...8 RTAA IOM 3 ...

Page 24: ...24 RTAA IOM 3 ...

Page 50: ...50 RTAA IOM 3 Figure 30 Refrigerant Circuit Identification ...

Page 52: ...52 RTAA IOM 3 Figure 31 Remote Evaporator Piping Example ...

Page 59: ...59 RTAA IOM 3 Continued from Previous Page See Notes on Next Page ...

Page 63: ...63 RTAA IOM 3 Continued from Previous Page See Notes on Page 61 ...

Page 65: ...65 RTAA IOM 3 Continued from Previous Page See Notes on Page 61 ...

Page 76: ...76 RTAA IOM 3 ...

Page 92: ...92 RTAA IOM 3 Figure 51 Operator Interface Controls ...

Page 120: ...120 RTAA IOM 3 ...

Page 127: ...127 RTAA IOM 3 Continued from Previous Page 2307 1566C ...

Page 128: ...128 RTAA IOM 3 Figure 57 Unit Sequence of Operation RTAA 130 to 200 Tons 2306 9122A ...

Page 132: ...132 RTAA IOM 3 Figure 58 Operator s Log ...

Page 138: ...138 RTAA IOM 3 ...