87

RTAA-IOM-3

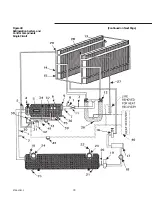

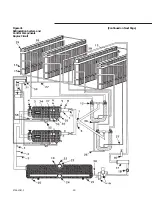

Operating Principles –

Adaptive Control

™

Microprocessor Logic

General

The exclusive Trane Adaptive Control

logic is comprised of a system of

individual modules called the Unit

Control Module (UCM), located in the

Control Panel. The system consists of

four types of microprocessor-based

components and the operator interface,

as shown in Figures 47 thru 51. The

processors are:

Chiller Module (Base or Deluxe) - 1U1

Communication and Setpoint Reset

Option Module - 1U2

Expansion Valve Module - 1U3

Compressor Module (one per

compressor) - 1U4, 1U5, 1U6, 1U7

Slave Expansion Valve Module

(240 -400 ton units) - 1U8

The Adaptive Control Chiller Module is

available in two versions, a base model

and a deluxe model. The deluxe model

offers the additional features of:

1. Under/Over Voltage Protection

(Includes U/O voltage sense

transformer).

2. Display of Compressor Starts and

Hours

3. Display of % Line Volts

4. Alarm/Running/Max Capacity

Contacts

Local operator interface with the

system is accomplished using the four

display buttons on the LICK Data

readouts are shown on the seven-digit,

digital display. The three-position

switch is used to set chiller operation.

Digital Display

The digital display shows:

•

both operating and diagnostic codes

•

compressor status indicators

•

settings of a local setpoints and

adjustments

•

actual controlling setpoints

•

specified temperatures

•

specified pressures

•

enable/disable status of features and

options

•

selection status of Sl units or English

units for display of temperatures and

pressures

All display segments and any used

decimal points will be briefly turned on

to provide a visual test of their

operation , following a Power-On-

Reset. The chiller operating codes (“A”

prefix) will then be displayed. The data

to be shown on the digital display is

selected by using the Display Up and

Display Down keys. Changing of the

display and menus is discussed below.

The digital display will light an indicator

at the bottom of the display, above the

“A”, “B”, “C” or “D” and circuit 1 or

circuit 2. In Menu 0, these indicators

show which compressor/circuit is

running. In Menu 2, these indicators

show which compressor/circuit is

related to the displayed parameter.

A “Circuit Lockout” indicator will be lit

if either circuit is enabled (E) in Menu 1

A (Circuit Lockout) or either circuit is

“OFF” on its external Circuit Lockout

contacts and Menu 3B, (External Circuit

Lockout) is enabled (E).

Summary of Contents for RTAA-130

Page 2: ... American Standard Inc 1991 ...

Page 8: ...8 RTAA IOM 3 ...

Page 24: ...24 RTAA IOM 3 ...

Page 50: ...50 RTAA IOM 3 Figure 30 Refrigerant Circuit Identification ...

Page 52: ...52 RTAA IOM 3 Figure 31 Remote Evaporator Piping Example ...

Page 59: ...59 RTAA IOM 3 Continued from Previous Page See Notes on Next Page ...

Page 63: ...63 RTAA IOM 3 Continued from Previous Page See Notes on Page 61 ...

Page 65: ...65 RTAA IOM 3 Continued from Previous Page See Notes on Page 61 ...

Page 76: ...76 RTAA IOM 3 ...

Page 92: ...92 RTAA IOM 3 Figure 51 Operator Interface Controls ...

Page 120: ...120 RTAA IOM 3 ...

Page 127: ...127 RTAA IOM 3 Continued from Previous Page 2307 1566C ...

Page 128: ...128 RTAA IOM 3 Figure 57 Unit Sequence of Operation RTAA 130 to 200 Tons 2306 9122A ...

Page 132: ...132 RTAA IOM 3 Figure 58 Operator s Log ...

Page 138: ...138 RTAA IOM 3 ...