130

RTAA-IOM-3

System Restart After

Extended Shutdown.

Follow the procedures below to restart

the unit after extended shutdown:

1. Verify that the liquid line service

valves, oil line, compressor

discharge service valves and suction

service valves (if installed) are open

(backseated).

Caution: To prevent damage to the

compressor, be sure that all

refrigerant valves are open before

starting the unit.

2. Close the main disconnect and unit

mounted disconnect (if installed) to

energize the compressor sump

heaters. If the optional control

transformer is not installed, it will be

necessary to close the disconnect for

115 VAC power to 1TB3-1 and

1TB3-2.

Caution: The compressor sump

heaters must be energized for a

minimum of 24 hours prior to unit

operation, to prevent compressor

damage caused by liquid

refrigerant in the compressor at

start-up.

3. Maintain power to the evaporator

heat tape connections.

4. Check the oil separator oil level. See

“Oil Separator Level Check”.

5. Fill the evaporator chilled water

circuit. Refer to Table I for evaporator

liquid capacities. Vent the system

while it is being filled. Open the vent

on the top of the evaporator during

filling and close when filling is

completed.

Caution: Do not use untreated or

improperly treated water.

Equipment damage may occur.

6. Close the fused-disconnect switch

that provides power to the chilled

water pump.

7. Start the chilled water pump and,

while chilled water is circulating,

inspect all piping for leakage. Make

any necessary repairs before starting

the unit.

8. While the chilled water is circulating,

adjust the chilled water flow and

check the chilled water pressure drop

through the evaporator. Refer to

“Water System Flow Rates” and

“Water System Pressure Drop”.

9. Adjust the flow switch on the

evaporator piping (if installed) for

proper operation.

10. Stop the chilled water pump. The

unit is now ready for start-up as

described in “Start-Up Procedures”.

Summary of Contents for RTAA-130

Page 2: ... American Standard Inc 1991 ...

Page 8: ...8 RTAA IOM 3 ...

Page 24: ...24 RTAA IOM 3 ...

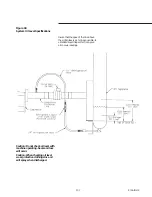

Page 50: ...50 RTAA IOM 3 Figure 30 Refrigerant Circuit Identification ...

Page 52: ...52 RTAA IOM 3 Figure 31 Remote Evaporator Piping Example ...

Page 59: ...59 RTAA IOM 3 Continued from Previous Page See Notes on Next Page ...

Page 63: ...63 RTAA IOM 3 Continued from Previous Page See Notes on Page 61 ...

Page 65: ...65 RTAA IOM 3 Continued from Previous Page See Notes on Page 61 ...

Page 76: ...76 RTAA IOM 3 ...

Page 92: ...92 RTAA IOM 3 Figure 51 Operator Interface Controls ...

Page 120: ...120 RTAA IOM 3 ...

Page 127: ...127 RTAA IOM 3 Continued from Previous Page 2307 1566C ...

Page 128: ...128 RTAA IOM 3 Figure 57 Unit Sequence of Operation RTAA 130 to 200 Tons 2306 9122A ...

Page 132: ...132 RTAA IOM 3 Figure 58 Operator s Log ...

Page 138: ...138 RTAA IOM 3 ...