135

RTAA-IOM-3

Maintenance

General

This section describes specific

maintenance procedures which must

be performed as a part of the normal

maintenance program for this unit. Be

certain that electrical power to the unit

is disconnected before performing

these procedures.

WARNING: Position all electrical

disconnects in the “OPEN”

position and lock them, to

prevent injury or death due to

electrical shock.

Coil Cleaning

Clean the condenser coils at least once

each year, or more frequently if the unit

is located in a “dirty” environment.

This will maintain proper unit operating

efficiencies. Follow the detergent

manufacturer’s instructions as closely

as possible to avoid damage to the

coils.

To clean the coils, use a soft brush and

a sprayer, either the garden, pump-up

type or a high-pressure type. A high-

quality detergent, such as “Trane Coil

Cleaner, CHM-0002” is recommended

for both standard and “Blue-Fin” coils.

Note:

If the detergent mixture is

strongly alkaline (pH value greater than

8.5), an inhibitor must be added.

Chemically Cleaning

The Evaporator

The chilled water system is a closed-

loop and therefore should not

accumulate scale or sludge. If the

chiller becomes fouled, first attempt to

dislodge the material by backflushing

the system. If unsuccessful after several

attempts, chemically clean the

evaporator.

Caution: Do not use an acid type

cleaning agent that will damage

steel, galvanized steel,

polypropylene, or internal copper

components.

With this information, water treatment

firms will be able to recommend a

suitable chemical for use in this

system.

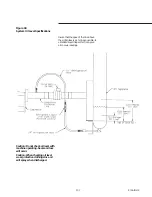

A typical configuration for chemical

cleaning is shown in Figure 59. The

supplier of the cleaning chemicals must

provide or approve:

All of the materials used in this

configuration

The amount of chemicals used

The length of time the chemicals are

used

Any safety precautions and

handling instructions

Domestic Water

Heater – Tube Cleaning

The water tubes may be mechanically

cleaned with a wire brush. This can be

done by isolating the water supply to

the Domestic Water Heater, relieving

the water pressure, and removing the

access plugs at the rear of the unit.

Once the tubes have been brushed and

scale has been loosened, flush the

water tubes with fresh water, reinstall

the access plugs and return to service.

The circulator should be shut off during

this operation and all air must be bled

from the water circuit when returning

the unit to operation. Be certain to use

an approved pipe sealant on the

threaded access plugs when

reinstalling to prevent water leaks.

Figure 59

Chemical Cleaning Configuration

Summary of Contents for RTAA-130

Page 2: ... American Standard Inc 1991 ...

Page 8: ...8 RTAA IOM 3 ...

Page 24: ...24 RTAA IOM 3 ...

Page 50: ...50 RTAA IOM 3 Figure 30 Refrigerant Circuit Identification ...

Page 52: ...52 RTAA IOM 3 Figure 31 Remote Evaporator Piping Example ...

Page 59: ...59 RTAA IOM 3 Continued from Previous Page See Notes on Next Page ...

Page 63: ...63 RTAA IOM 3 Continued from Previous Page See Notes on Page 61 ...

Page 65: ...65 RTAA IOM 3 Continued from Previous Page See Notes on Page 61 ...

Page 76: ...76 RTAA IOM 3 ...

Page 92: ...92 RTAA IOM 3 Figure 51 Operator Interface Controls ...

Page 120: ...120 RTAA IOM 3 ...

Page 127: ...127 RTAA IOM 3 Continued from Previous Page 2307 1566C ...

Page 128: ...128 RTAA IOM 3 Figure 57 Unit Sequence of Operation RTAA 130 to 200 Tons 2306 9122A ...

Page 132: ...132 RTAA IOM 3 Figure 58 Operator s Log ...

Page 138: ...138 RTAA IOM 3 ...