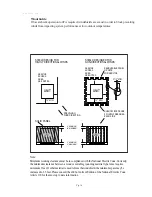

Section III - Minimum Operating Clearances

This section discusses installating the XR style condensing unit / heat pump where spacing is limited.

When installing Trane outdoor units in a location where clearance to other units, walls, fences, etc. is

limited, the concerns listed below must be addressed:

1. System Operation - Adequate airflow must be provided to and away from the condensing unit / heat

pump in order to enable appropriate heat transfer. If this is accomplished, head pressure will remain

within an effective operating range.

2. System Servicability - Sufficient working space must be allowed for the HVAC service technician to

properly maintain the condensing unit / heat pump. Furthermore, space must be allowed for major

component change out in the event of a failure. Working space is determined by the Local, State and

National Codes. (See National Electric Code Table 110.26 for explanation.)

3. Space Maintenance - Appropriate area must be allowed in order to maintain the ground area where

the units are positioned to prohibit debris from collecting on the panels, thus further providing

unobstructed airflow to the condensing unit.

3. State, Local Codes, and National Codes shall prevail. Check with the local jurisdiction before

installation to assure compliance.

Numerous projects require minimum clearances between outdoor units and adjacent walls, fences and other

units. The obstruction in question is usually one of the following:

1. One or more walls of an adjacent building.

2. Fences or barriers provided to reduce sound transmission or visually screen the equipment.

3. Other outdoor units in a multi-unit installation.

4. A combination of the above.

5. Overhangs

The prime considerations involved in establishing minimum clearances are:

1. Adequate airflow to the outdoor coil with minimum recirculation.

2. Service access to the equipment.

3. Compliance with the National Electric Code and other applicable codes.

4. Design temperature - Design temperatures greater than 105F require additional consideration.

I. In order to assure that adequate airflow reaches the condensing unit, size free air passages at 300

Feet Per Minute maximum velocity. See condensing unit airflow performance on page 23 of this

document.

II. The importance of providing proper service access to equipment cannot be overemphasized. The HVAC

service technician’s job may be performed with greater ease and lower cost if adequate service space is

allowed.

III. Knowledge of the National Electric Code and other applicable codes for the job sight location is a

necessity in order to satisfy local inspectors. These codes are in place for service as well as safety.

IV. Be sure to read all provisions and footnotes contained in this document. When ambient temperatures

exceed 105F, more space may be required for minimum operating clearances.

Pg. 9