Installation

CVRF-SVN005C-EN

19

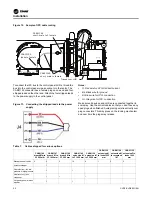

1. Installing Symbio™ stepper actuator.

a. Determine the inlet guide vane stroke by manually

closing and opening the vanes and accurately

measuring the length of travel.

b. Record this value as it will be used when performing the

post conversion checkout.

2. Remove the existing IGV actuator and existing conduit and

wire.

3. Install the new IGV actuator on the chiller.

a. Use the connecting hardware retained when the old

actuator was removed.

b. Use the existing actuator mounting plate, piston yoke

and mounting hardware to install the new electric

actuator.

The motor can be rotated 180 degrees to accommodate

existing hardware. The actuator rod may be connected to

the mounting plate at the compressor housing or to the

vane linkage.

NOTICE

Equipment Damage!

Failure to ensure that the 0 degree vane position

corresponds with the actuator fully closed when

mounting the actuator could result in severe damage to

the machine.

Figure 11. Installed stepper IGV actuator

4. The IGV ships in a mid-position. The first time the IGV is

powered up, it will drive closed. This may mean travel as

much as 1 inch. Disconnect the IGV actuator from the IGV

linkage until fully retracted.

Running the IPC Bus

There are several ways to string the IPC communication bus

on the chiller. The Symbio™ retrofit kit includes a general wire

kit that has several different types of wires. An example of a

wiring layout can be seen in

. Each application

will vary depending on the options. You may have extra cables,

or may be short needed cables. Extra cables can be ordered

through your local Trane Parts Center. Refer to PART-SVB16*-

EN for identification of individual cables.

WARNING

Hazardous Voltage w/Capacitors!

Failure to disconnect power and discharge capacitors

before servicing could result in death or serious injury.

Disconnect all electric power, including remote

disconnects and discharge all motor start/run

capacitors before servicing. Follow proper lockout/

tagout procedures to ensure the power cannot be

inadvertently energized. For variable frequency drives

or other energy storing components provided by Trane

or others, refer to the appropriate manufacturer’s

literature for allowable waiting periods for discharge of

capacitors. Verify with a CAT III or IV voltmeter rated per

NFPA 70E that all capacitors have discharged.

WARNING

PPE for Arc/Flash Required!

Failure to wear appropriate PPE could result in death or

serious injury.

On this unit, if the handle shield is cracked the circuit

breaker could arc/flash when reset. To avoid being

injured, technicians MUST put on all necessary

Personal Protective Equipment (PPE), in accordance

with NFPA70E for arc/flash protection, PRIOR to

entering the starter panel cabinet.