Installation

CVRF-SVN005C-EN

21

Purge Control Installation

Important:

Be sure to retain all existing purge safety

controls!

The purge power line connections for the power to the unit

should be wired per the purge wiring diagram. In general the

115 Vac power for the purge originates from the unit control

panel. In the new control panel a circuit breaker 1Q2 is

provided to power the purge. A neutral connection can be

found on the 1X1 terminal strip.

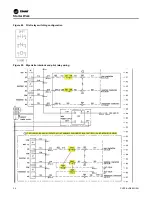

PRGC Purifier Purge

The PRGC Purifier™ purge uses UCP2-based

communications and does not communicate with Tracer®

AdaptiView™ controls. To convert the purge to a standalone

purge, order KIT02586 from a Trane Parts Center and install it,

making sure to install a jumper between terminals J1-5 and J1-

6 on the 3UI module when doing the conversion. A PRGC

requires a compressor running signal connected to J26, 1 and

2 on 3U1 in the purge to operate in the auto or adaptive modes.

Use the Compressor Running contact closure from the quad

relay LLID - 1A8, connected to 115 Vac purge source.

PRGD, PRGG and PRGF EarthWise Purge

If a stand-alone EarthWise purge (CH530 control) exists on the

chiller, it will need some hardware changes to work with the

Symbio™ retrofit controls. If the purge is a new installation with

the Symbio™, then skip to

.

1. The compressor running LLID (3A6) will not be needed,

disconnect and remove.

2. The condenser saturated refrigerant temperature LLID

(purge liquid temperature) will not be needed, disconnect

and remove.

3. The existing 120-27 Vac transformer and DC power supply

in the purge is undersized and should be removed. The

purge control will be powered by the Symbio™ panel

power supply.

4. Remove and save purge power supply LLID.

5. Remove IPC bus cable from power supply LLID. (Ensure

remaining LLIDs are still connected to IPC bus).

6. It is optional to remove and discard the wires (303A, 304A,

and 318A) from control power transformer to this power

supply LLID (3A5).

7. Disconnect the cable from the DynaView to the power

supply LLID.

8. Remove the tilt bracket from the purge base. DynaView

can remain attached to the tilt bracket panel.

9. Connect the IPC bus from the control panel to the IPC bus

for the purge using an IPC bus cable.

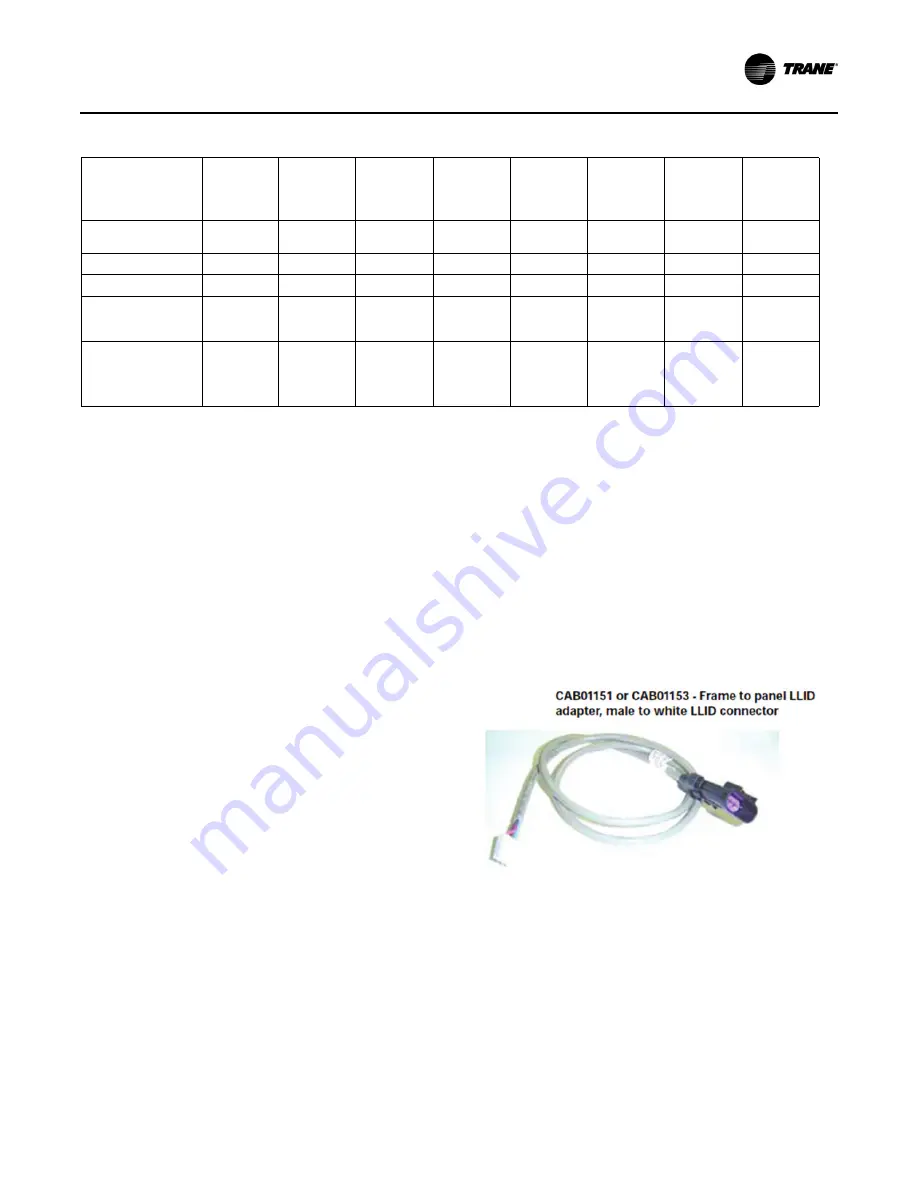

Figure 14. CABO1151 or CABO1153

Hot gas bypass—pulse

actuator

1

1

Cold water reset

1

8

Enhanced protection

1

2

1

3

Chilled/tower water flow

display, standard

accuracy

2

Heat recovery / aux

condenser water flow

display, standard

accuracy

1

(a) The letters M and F represent male and female connectors.

Table 7.

Cables shipped for various options (continued)

CAB01146

branch M

(a)

to

2F 500 mm

CAB01147

branch M to

2F 1000 mm

CAB01148

branch M to

3F 500 mm

CAB01149

extension M

to F 1000 mm

CAB01150

extension M

to F 2000 mm

CAB01152

extension M

to leads 1000

mm

CAB01154

extension M

to receptacle

1M

CAB01155

extension F to

leads 1000

mm