TRANE

R

Installation

7

Foundation

When selecting and preparing the unit

site, follow these guidelines:

1. Ensure that the site can support the

total weight of the unit. Unit weight

figures only provide total gross

weights and do not include the

additional weight for water in any

coils.

2. Confirm that the foundation of the

mounting platform is large enough

to include the unit dimensions plus

service plus service access.

3. The floor or foundation must be

level for correct coil drainage and

condensate flow.

4. Provide adequate lighting for

maintenance personnel to perform

maintenance duties.

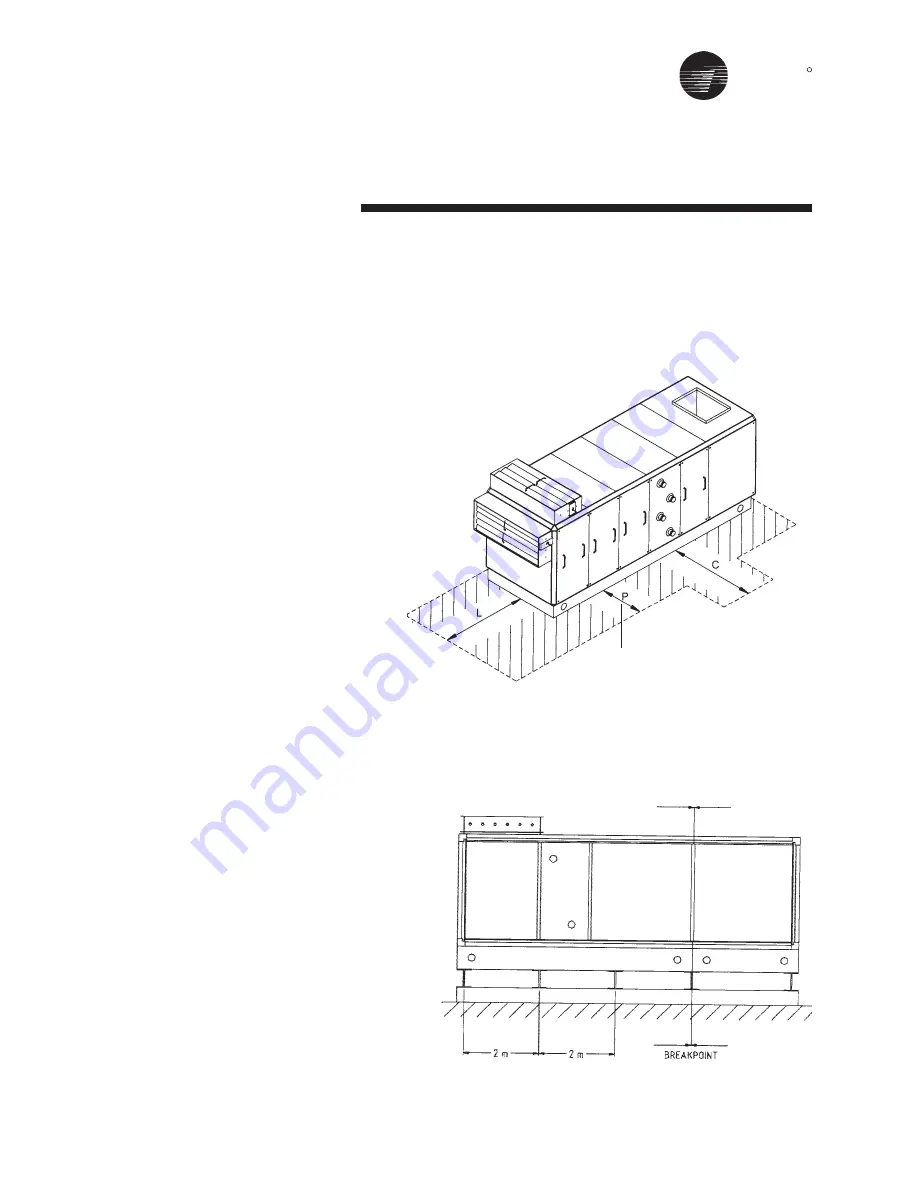

5. When the unit is positioned on site,

there must be sufficient space

around the unit to ensure that correct

operation and effective main-

tenance can be carried out. Figure

6 gives recommended space

allowances.

•

On the designated access side of

the unit, working areas must have

minimum 1 mtr, space (P).

•

Allowance for coil connections,

dimension “C” must be dimension

200mm + unit width.

•

A clear unobstructed area before

and after an air intake or discharge

is required to ensure correct air

movement. The width of the area

must be >= the width of the unit, and

the depth (dimension “L”) must be

>= 0.5 x the overall unit height.

Complete reinforced concrete

foundations are suitable or strip

foundations may also be used (see

Figure 7).

In the case of strip foundations,

concrete or steel supports are

premissible, but support is required

under breakpoints and every 2 m along

the unit base.

Figure 7 - Air Handling Unit Steels Foundation

Figure 6

P = 1 MTR min

Summary of Contents for TRANE Quantum CLCPEuro

Page 2: ...TRANE R...

Page 6: ...TRANE R 2 CLCPXP Model Nomenclature...

Page 7: ...TRANE R CLCPEURO Model Nomenclature 3...

Page 13: ...TRANE R Assembly Installation CLCPEuro CLCPXP External connection 9...

Page 14: ...TRANE R Assembly Installation CLCPEuro Break Point 25mm Frame to Frame 10...

Page 15: ...TRANE R 11 Assembly Installation CLCPEuro Break Point 25mm Panel to Frame...

Page 16: ...TRANE R 12 Assembly Installation CLCPEuro Break Point 2 50mm Frame to Frame...

Page 17: ...TRANE R Assembly Installation CLCPEuro Break Point 2 50mm Panel to Frame 13...

Page 18: ...TRANE R Assembly Installation CLCPEuro Paneling 14...

Page 19: ...TRANE R Assembly Installation CLCP XP Break Point 15...

Page 20: ...TRANE R Assembly Installation CLCP XP Break Point 16...

Page 21: ...TRANE R 17 Assembly Installation CLCP...

Page 22: ...TRANE R Assembly Installation CLCP 18...

Page 36: ...TRANE R Maintenance 32 Figure 18 Belt Tension Measurement...

Page 39: ...TRANE R 35 Trouble Analysis Pulley and Belt...

Page 45: ...TRANE R Appendix B HDT Unit Weight CLCPXP 41...

Page 46: ...TRANE R Appendix B HDT Unit Weight CLCPXP 42...

Page 47: ...TRANE R Appendix B HDT Unit Weight CLCPXP 43...

Page 48: ...TRANE R Appendix B VDT Unit Weight CLCPXP 44...

Page 53: ...TRANE R Appendix D Filter and Quantity 49 Filter Dimension and Arrangement Final Filter HEPA...

Page 57: ...TRANE R Typical Wiring Diagram Starter Star Delta 380 420V 3Phase 4Wires ELCB Standard 53...

Page 58: ...TRANE R 54 Typical Wiring Diagram Starter Dol 380 420V 3Phase 4Wires ELCB Standard...

Page 59: ...TRANE R 55 Typical Wiring Diagram Starter Dol 380 420V 3Phase 4Wires Standard...

Page 62: ...TRANE R 58 Typical Wiring Diagram Starter Dol 380 420V 3Phase 4Wires Standard...

Page 65: ...TRANE R 61 Typical Wiring Diagram Starter Star Delta 380 420V 3Phase 4Wires Standard...

Page 68: ...TRANE R 64...

Page 70: ...TRANE R 66...

Page 71: ...TRANE R...