Type

Code

number

A

B

C

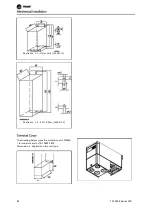

TR1 2803-2815 200-240 V, TR1 2805-2815 380-480 V

195N2118

47

80

170

TR 2811ET 200-240 V, TR 2811ET 380-480 V

195N2119

47

95

170

TR 2822 200-240 V, TR2822-2840 380-480 V

195N2119

47

95

170

TR1 2840 200-240 V, TR1 2855-2875 380-480 V

195N2120

47

145

170

TR1

2880-2882

380-480

V

195N2126

47

205

245

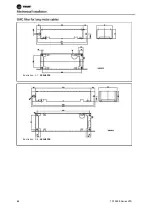

Table 5. 1: Dimensions

TR1

2800

Series

VFD

85

IP 21 Solution

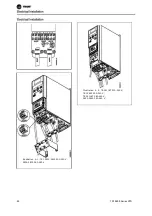

Mechanical Installation

Summary of Contents for VarioTrane TR1 2800 Series

Page 2: ...T TR R1 1 2 28 80 00 0 S Se er ri ie es s V VF FD D 1 1...

Page 3: ...2 2 T TR R1 1 2 28 80 00 0 S Se er ri ie es s V VF FD D...

Page 4: ...TR1 2800 Series VFD 3...

Page 7: ...6 TR1 2800 Series VFD...

Page 87: ...Illustration 5 7 192H4719 Illustration 5 8 192H4720 86 TR1 2800 Series VFD...

Page 95: ...Branch Circuit Protection Short circuit protection 94 TR1 2800 Series VFD...

Page 107: ...All about TR1 2800 Series VFD 106 TR1 2800 Series VFD...