CHAPTER 1: INTRODUCTION TO THE Neptune 4500 SERIES DIGITAL INDICATORS

The Neptune 4500 Series Digital Indicator is a general purpose, industrial grade weight indicator.

All models operate identically, can readout up to 50,000 display divisions and can supply enough

current for up to 4-350

Ω

load cells. All setup parameters may be entered via the front panel keys,

including calibration.

If your Neptune Model 4500 Series Digital Indicator is part of a complete floor scale or has been

installed for you, you may skip to Chapter 7 for operating instructions. Prior to using the indicator,

please read this chapter carefully and completely. Store the manual in a safe and convenient

place so it will be available if you have questions concerning the operation of the scale.

If you are an installer, the indicator's installation and wiring instructions are found in Chapter 2.

The indicator contains two main setup menus: The Setup (“F”) menu, which configures the

indicator to your weigh platform and the User (“A”) menu, which configures the serial

communication port and enables some user options. Chapter 3 gives an overview and explains

how to use the two front panel keys to maneuver and save settings in both menus. Chapters 4

and 5 explain the Setup and User Menu options, respectively. Chapter 6 covers system

calibration. Prior to installing the indicator, please read this manual carefully and completely.

Store the manual in a safe and convenient place so it will be available if you have questions

concerning the setup and operation of the scale.

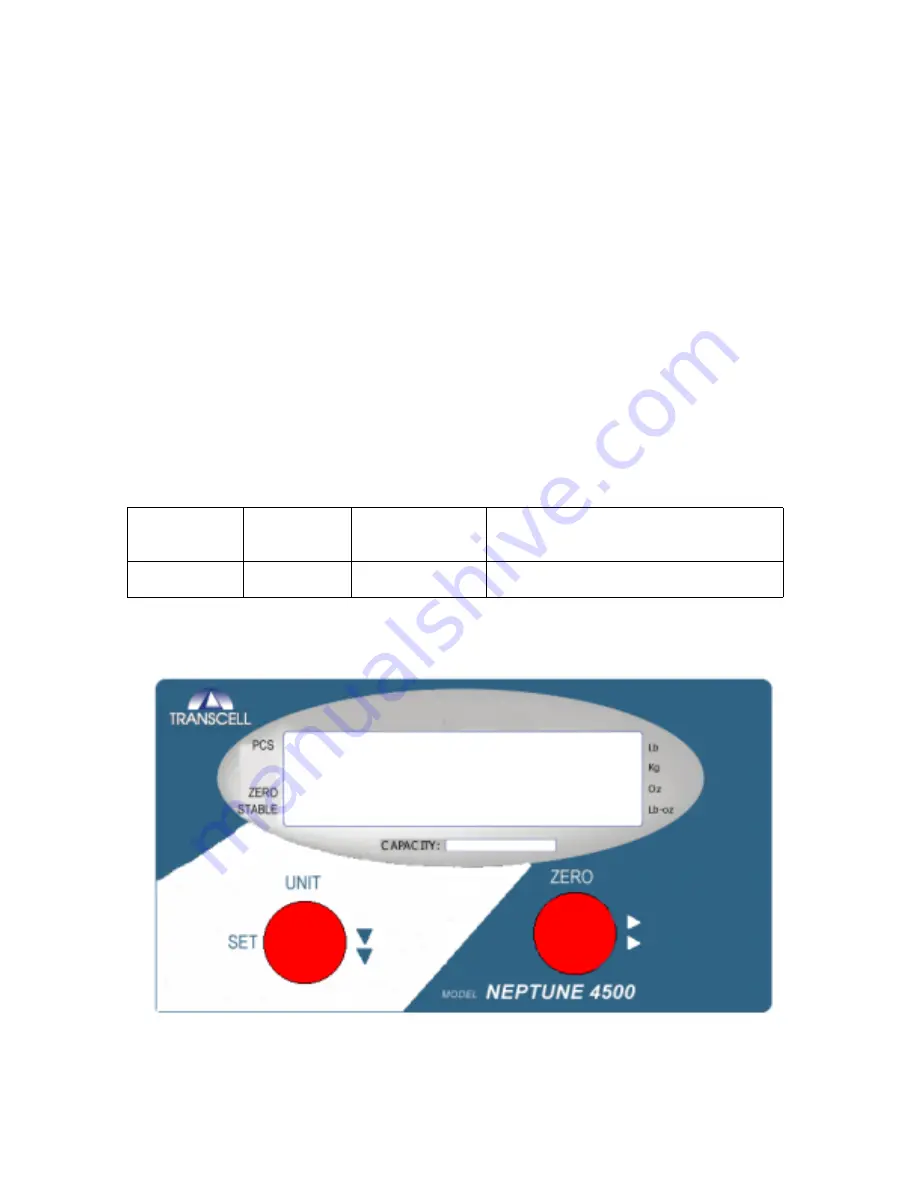

MODEL DISPLAY

TYPE

ENCLOSURE

TYPE

POWER SOURCE

Neptune 4500

LED

Stainless Steel

110/220 VAC, 50/60 Hz

TABLE 1-1: Neptune Series Product Matrix

FIGURE 1-1: Neptune 4500 Front Panel

Neptune 4500 Page 1-1