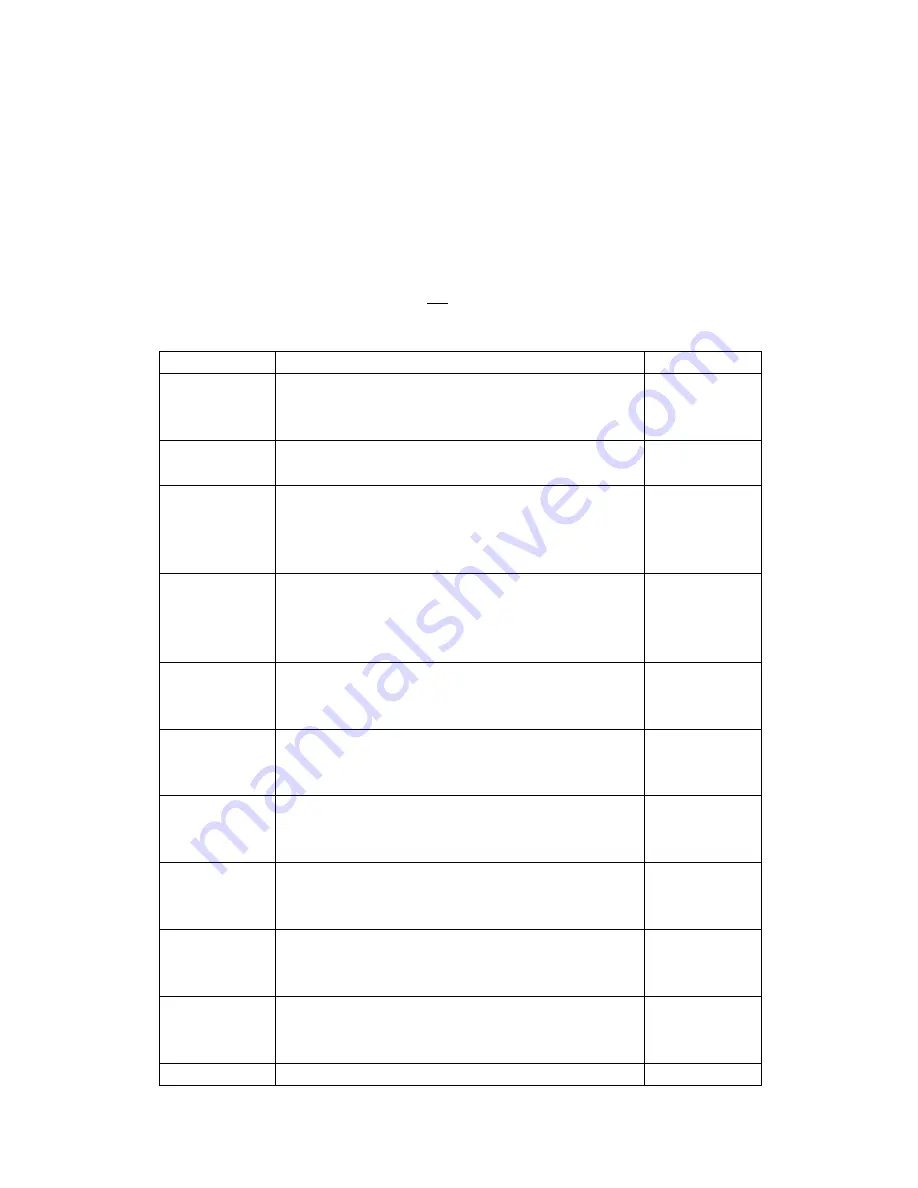

Setup Menu Descriptions

This section provides more detailed descriptions of the selections found in the Setup

Menu Chart.

Factory-set defaults are shown in bold with a checkmark (√ ).

Table 4-1 shows the selections that are not allowed for “Legal-for-Trade” applications.

Name / Code

Description

Code / Value

F1

Graduations

Specifies number of full-scale graduations. Value

should be consistent with legal requirements and

environmental limits on the useful system resolution.

1-100000

F2

AD Frequent

10Hz, 80Hz

F3

Zero Track

Band

Selects the range within which the scale will

automatically zero. Note that the scale must be in

standstill to automatically zero. Selections are in

Display Divisions.

0d, 0.5d√, 1d,

3d, 5d

F5

Motion Band

Sets the level at which motion is detected by

comparing the present display update with the

previous one. Maximum value varies depending on

local regulations.

1d√, 3d,

5d,10d

F6

Digital Filter

Averages weight readings to produce higher stability.

The higher the filter setting, the greater the stability

but the slower the indicator’s response time.

FAST--fast

NNEd--middle

SLO—slow

F8

Calib. Unit

Selects the primary base unit to be used in the

calibration process.

“1”= primary unit is kN “2”= primary unit is mV/V

1√, 2

F9

Display

Divisions

Determines the desired weight increments. Value

should be consistent with legal requirements.

1√, 2, 5, 10,

20, 50

F10

Decimal Pt.

Determines location of the decimal point.

0√, 0.0, 0.00,

0.000, 0.0000,

0.00000

F16

Zero

Calibration

Places indicator in the zero calibration routine. The

default unit is kN.

F17

Span

Calibration

Places indicator in the span calibration routine. The

default unit is kN.

F18

Actuates the function that allows you to view both the