ENGLISH

54

www.trapp.com.br

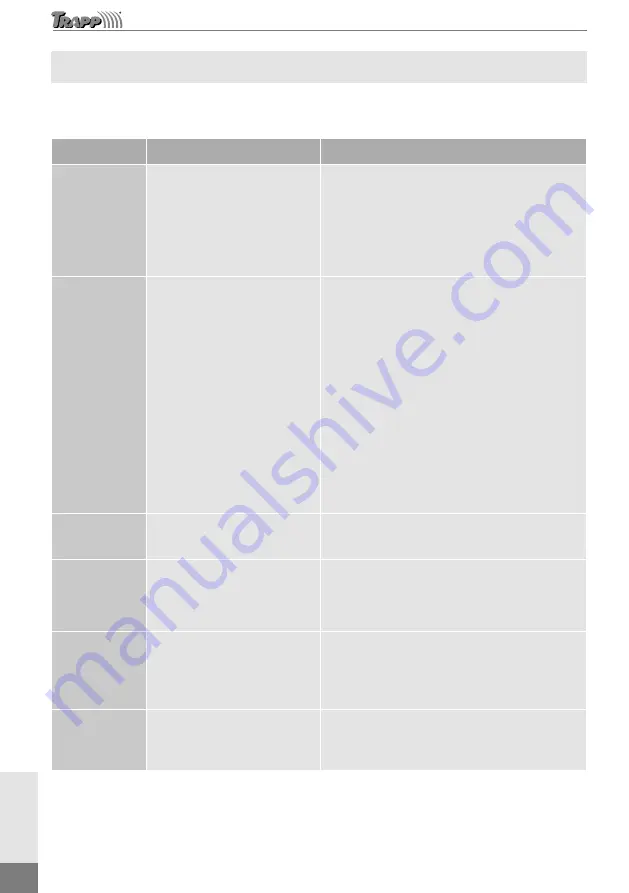

Useful Suggestions

Throghout the use of the shredder situations and or problems may occur, for which we present some

suggestions:

Trouble

Probable Cause

Solution

Equipment

jammed

Excess feeding or overload. Due

to this motor cannot achieve

required rotation, and the material

accumulates in the shredder

(continuous use under this

condition, can cause motor burn-

out due to overload).

Turn OFF shredder immediately and wait for motor

to stop. Open hatch and remove the excess material

inside shredder, close hatch. Once shredder is ready

to operate, turn ON the motor, and wait until rotation

reaches its full speed, only then resume work. Maintain

a steady and regulated amount of input, so as not to

overload motor.

Low production

1.

Insufficient feeding of the

shredder.

2. Motor rotation lower than

specified.

3. Moist or green produce.

4. Adjustment on shredder is not

consistent with the material in

use.

1. Maintain a continuous feeding flow, yet not over-

feeding which may cause the shredder to jam.

2. Verify if purchased motor to be installed on

shredder (shredder sold without motor) is

compatible accoding to specifications (see

sticker on shredder). If motor rotation is below

specification, the hammers will be delayed

causing low production.

3. When using funnel only grind dry grains and/

or dry produce. Grinding moist or green grains/

produce will clog and obstruct strainer.

4. Select different strainer for your choice application

(coarse or fine).

Irregular chopping

1. Unsharpened cutting blades.

2. Worn or unbalanced.

1. Sharpen cutting blades (page 50).

2. Follow procedure indicated (page 50).

Difficulty

grinding dry

grains

1. Worn or damaged hammers.

2. Hammers are jammed.

1. Revert position or substitute hammers (page 51).

2. Always clean shredder after usage, especially after

chopping green crop.

Difficulty

starting motor

1. Excess or overload of produce.

2. Drop of high tension or power

source.

1. Stop feeding shredder, and keep motor running

until clear.

2. Consult electrician to check power source.

Excessive

vibrating

1. Attachment screws loose on

the rack structure (as per the

model on page 33) or loose or

unbalanced disc.

1. Check the assembly instructions on page 40 and

41 and tighten the screws. Check the disc and

attachment screws. If the problem persists, seek

out an TRAPP-approved Technical Assistant.

Summary of Contents for TRF 300

Page 58: ...Notas Notes...

Page 59: ......