-12-

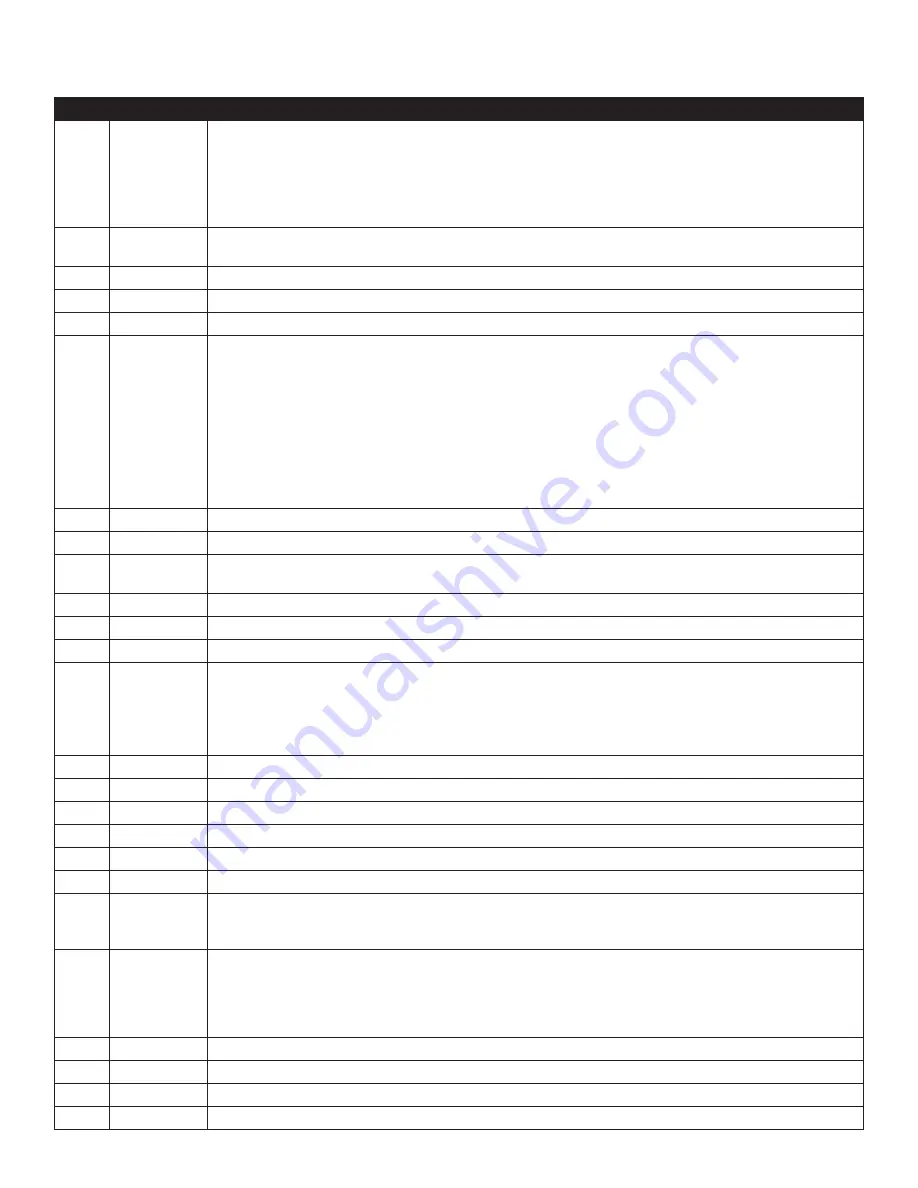

PAR

RANGE

DESCRIPTION

DDM

RT;

LT;

SP;

DEF

Defrost display mode. During defrost the display will show:

RT

: the real temperature;

LT

: the last temperature before defrost;

SP

: the current setpoint value;

DEF

: “dEF”.

DDY

0...60min

Display delay. The display shows the information selected with parameter DDM during defrost

and for DDY minutes after defrost termination.

FID

NO/YES

Fans active during defrost.

FDD

-58...180°

Evaporator fan re-start temperature after defrost.

FTO

0...120min Maximum evaporator fan stop after defrost.

FCM

NON;

TMP;

TIM

Fan mode during thermostatic control.

NON

: The fans remain ON all the time;

TMP

: Temperature-based control. The fans are ON when the compressor is ON. When the

compressor is turned OFF, the fans remain ON as long as the temperature difference Te-Ta

is greater than FDT. The fans are turned ON again with FDH differential. (Te = Evaporator

temperature, Ta = Air temperature);

TIM

: Timed-based control. The fans are ON when the compressor is ON. When the compressor

is OFF, the fans switch ON and OFF according to parameters FT1, FT2,FT3

FDT

-12...0°

Evaporator-Air temperature difference for the fans to turn OFF after the compressor has stopped.

FDH

1...12°

Temperature differential for fan re-start.

Example: FDT = -1, FDH=3. In this case, after the compressor has stopped, the fans are OFF when

Te > Ta - 1 (FDT), whereas the fans are ON when Te < Ta - 4 (FDT-FDH).

FT1

0...180sec

Fan stop delay after compressor/heater stop. See Fig. 2

FT2

0...180

Timed fan stop in x10 seconds. With FT2=0 the fans remain on all the time.

FT3

0...180

Timed fan run in x10 seconds. With FT3=0, and FT2 > 0, the fans remain off all the time.

ATM

NON;

ABS;

REL

Alarm threshold management.

NON

: all temperature alarms are inhibited (the following parameter will be ACC).

ABS

: the values programmed in ALA and AHA represent the real alarm thresholds.

REL

: the alarm threshold is obtained by the sum of setpoint, thermostat differential and ALR/

AHR.

ALA

-58... 180°

Low temperature alarm threshold.

AHA

-58... 180°

High temperature alarm threshold.

ALR

-12... 0°

Low temperature alarm differential. With ALR=0 the low temperature alarm is excluded.

AHR

0... 12°

High temperature alarm differential. With AHR=0 the high temperature alarm is excluded.

ATI

T1; T2; T3

Probe used for temperature alarm detection.

ATD

0... 120 min Delay before alarm temperature warning.

ACC

0...52 weeks Condenser periodic cleaning. When the compressor operation time, expressed in weeks, matches

the ACC value programmed, “CL” flashes in the display. With ACC=0 the condenser cleaning warning

is disabled and CND disappears from Info Menu.

IISM

NON;

MAN;

ECO;

DI

Switchover mode to second parameter set

NON

: inhibition to use the second parameter group (the following parameter will be SB).

MAN

: button switches the two parameter groups over.

ECO

: automatic switchover to the second parameter group, when ECO conditions are detected.

DI

: switchover to the second parameter group when DIx input is on.

IISL

-58... IISH

Minimum limit for IISP setting.

IISH

IISL... 180° Maximum limit for IISP setting.

IISP

IISL... IISH Setpoint in mode 2.

IIH0

1... 10°

Thermostat OFF->ON differential in mode 2.

VI. CONTROL BASICS (continued)