-3-

III. c - INSTALLING LEGS OR CASTERS (cont

’

d):

Please note that Traulsen units are not designed to be

moved while on legs. If the unit requires moving, a

pallet jack or forklift should be used to prevent damage.

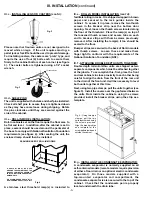

For installing casters, the casters are

“

plate

”

type, and

require the use of four (4) bolts each to secure them

firmly to the cabinet bottom at each corner (see figure

3). The caster bolts are tightened using a 1/2” socket

wrench.

III. d - SHELF PINS:

The unit is supplied with shelves and shelf pins installed.

Check all shelf pins to assure they are tightened down

as they may have come loose during shipping. Rotate

the pins clockwise until they are secured against the

side of the cabinet.

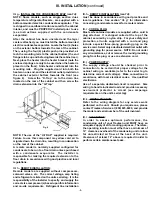

III. e - ROLL-IN MODEL INSTALLATION:

Roll-In cabinets set on the floor require the floor area to

be flat and level. In addition, after the cabinet is set in

place, sealant should be used around the perimeter of

the base to comply with National Sanitation Foundation

requirements (see figure 4). After sealing the unit, the

enclosed ramp should then be installed.

A stainless steel threshold ramp(s) is included to

III. INSTALLATION

(continued)

Fig. 4

SEALING BASE OF ROLL-IN MODELS

A SEALANT MUST BE USED

AROUND THE PERIMETER OF THE

BASE OF CABINET AS SHOWN TO

FULLY COMPLY WITH SANITARY RE-

QUIREMENTS.

A RECOMMENDED SEALANT IS

DOW CORNING SILASTIC RTV #732

Fig. 3

Threaded Holes

Caster

Fig. 2

III. e - ROLL-IN MODEL INSTALLATION (cont

’

d):

facilitate rolling in racks. It is shipped wrapped in brown

paper and secured to the rack guides inside the

cabinet. To secure it in place, remove the two thumb

screws in the breaker strip near the bottom door

opening. Next, loosen the thumb screws located along

the floor at the threshold. Place the ramp(s) on top of

the loosened thumb screws and secure tabs on each

end to breaker strips with thumb screws previously

removed. After installing the ramp(s), it too should be

sealed to the floor.

Bumper strips are secured to the back of Roll-In models

with thumb screws. Loosen these and make them

finger tight to conform with the requirements of the

National Sanitation Foundation (NSF).

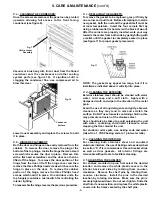

III. f - ATTACHING DOUBLE DEPTH UNITS TOGETHER:

Double depth roll-in/roll-thru units are shipped as two

separate components which must be attached together

at the jobsite. To accomplish this, first, place the front

and rear cabinets in close proximity to each other being

careful to align the drain from the front of the rear unit

to the drain of the front unit. It will be necessary to level

both units together at this time.

Next, using two pipe clamps, pull the units together (see

figure 5). Install the covers over the gap formed between

the units From inside the cabinets, using the screws

provided, install the breaker strips using the strip as a

template.

III. g - INSTALLING THE CONDENSATE EVAPORATOR:

A condensate evaporator is normally supplied on all

self-contained models (remote models require provision

of either a floor drain or an optional electric condensate

evaporator). On those models supplied with a

top-mounted evaporator coil compartment, the

condensate evaporator is also secured to the top of the

cabinet. Check that the condensate pan is properly

located underneath the drain tube.

Fig. 5 - Using two pipe

clamps, pull the two

units together and using

the screws provided.

Align the breaker strips

as a template for the

screw pattern inside and

outside the cabinet.