-4-

III. g - INSTALLING THE CONDENSATE EVAP (cont

’

d):

NOTE: Some models, such as single section dual-

temperature refrigerator/freezers, are supplied with a

bottom-mounted electric condensate evaporator. This

is shipped in a cardboard carton secured to the cabinet

interior, and must be PROPERLY installed prior to use

(see instructions supplied with the condensate

evaporator).

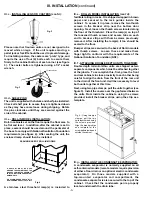

After the cabinet has been uncrated and the legs/

casters attached, you must install the bottom-mounted

electric condensate evaporator. Locate the four (4) holes

on the exterior bottom towards the rear of the cabinet.

Then, using the four (4) plastic push pins provided, at-

tach the mounting rails to the cabinet bottom (the end

flange is to be up and be facing towards the cabinet rear).

Next, place the heater into the heater bracket (note the

enclosed springs are only to be used when the heater is

placed on the floor). Slide heater and bracket into the

mounting rails. Plug the supplied cord into both the

heater on one end, and the electrical outlet provided on

the cabinet exterior bottom towards the front (see

figure 6). Screw the

“

U-Trap

”

on to the drain line

located on the rear of the cabinet and then screw the

drain extension into the

“

U-Trap.

”

NOTE: The use of the

“

U-TRAP

”

supplied is required.

Failure to use this component may allow cold air to

migrate down the drain line, resulting in condensation

on the rear of the cabinet.

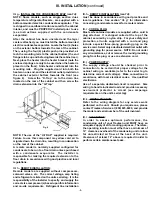

A remote model is normally supplied configured for

condensate to be run to a floor drain unless purchased

with a condensate evaporator. The installer is

responsible for making the required extension to the

floor drain in accordance with good practice and local

regulations.

III. h - REMOTE INSTALLATION:

Remote models are supplied without compressors,

solenoid valves, etc. The correct voltage, amp listing

and refrigerant are listed on the units serial tag. It is the

responsibility of the installer to specify and supply the

correct size compressor(s) based upon this information

and on-site requirements. Refrigerant line installation

III. INSTALLATION

(continued)

III. h - REMOTE INSTALLATION (cont

’

d):

must be done in accordance with good practice and

local regulations. See section

“

III. g

”

for information

concerning condensate removal for remote models.

III. i - CORD & PLUG:

Most self-contained models are supplied with a cord &

plug attached. It is shipped coiled at the top of the

cabinet, secured by a nylon strip. For your safety and

protection, all units supplied with a cord and plug

include a special three-prong grounding plug on the

service cord. Select only a dedicated electrical outlet with

grounding plug for power source. NOTE: Do not under

any circumstances, cut or remove the round grounding

prong from the plug, or use an extension cord.

III. j - POWER SUPPLY:

The supply voltage should be checked prior to

connection to be certain that proper voltage for the

cabinet wiring is available (refer to the serial tag to

determine correct unit voltage). Make connections in

accordance with local electrical codes. Use qualified

electricians.

Use of a separate, dedicated circuit is required. Size

wiring to handle indicated load and provide necessary

overcurrent protector in circuit (see amperage

requirements on the unit’s serial tag).

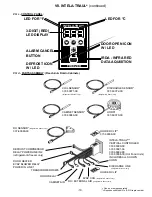

III. k - WIRING DIAGRAM:

Refer to the wiring diagram for any service work

performed on the unit. Should you require one, please

contact Traulsen Service at (800) 825-8220, and provide

the model and serial number of the unit involved.

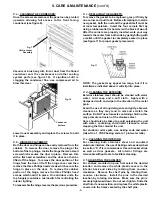

III. l - CLEARANCE:

In order to assure optimum performance, the

condensing unit of your Traulsen unit MUST have an

adequate supply of air for cooling purposes. Therefore,

the operating location must either have a minimum of

12

”

clearance overhead of the condensing unit or allow

for unrestricted air flow at the back of the unit.

Clearance of at least 12

”

above is required in order to

perform certain maintenance tasks.

Fig. 6