28

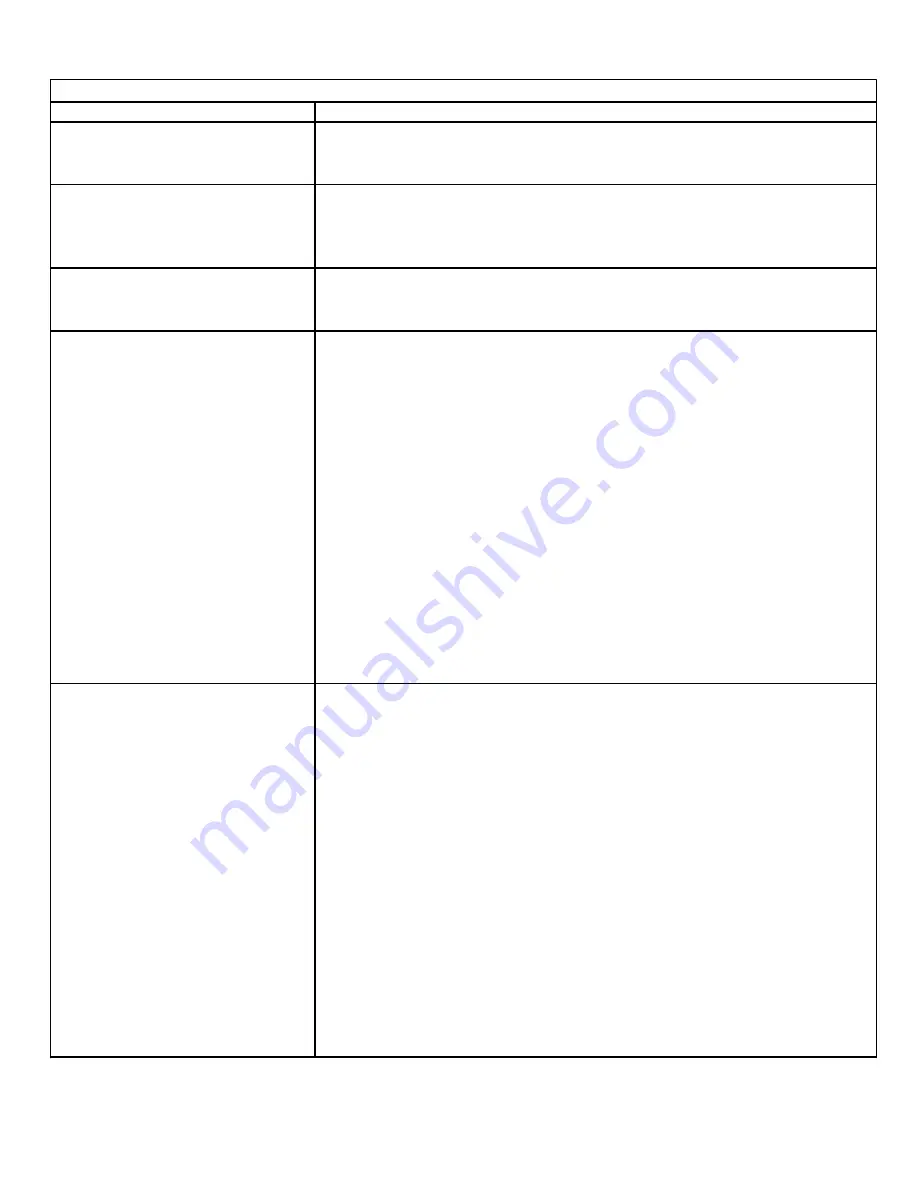

XIII. TROUBLE SHOOTING ( Continued)

CONDITIONS

POSSIBLE SOLUTIONS

CORROSION OCCURING ON

1.

Use a “Food Grade” Silicone and with all power off to the unit,

CONTROL BOARD

spread a light coating of the silicone on all exposed connections.

2.

Look for high humid conditions

UNIT TRIPS A GROUND

1.

Go to the relay box and with the power off to the unit pull all of

FAULT BREAKER

the wires off of terminal #1,and reinstall them one at a time. Once

you force the breaker to trip this will tell you which component

has failed

RBC200 NOT HOLDING

1.

The temperature must be equal from top to bottom in cabinet.

TEMP IN “IDLE” MODE

2.

The remote condenser will come on every other cycle on Control

Versions 1.12 and later.

RBC50 FOOD PROBE

1.

Should the “Food Probes” fail to read any temperature you will

HARNESS

need to check them for breaks in the wires or separation of the

insulation.

2.

Look at the “Sockets” in the ceiling of the box were the Food

Probes plug into for any broken pieces.

3.

Pull the Socket Plate down to inspect the top of the sockets for

broken wires or corrosion.

4.

Should the Harness be bad it will have to be replaced.

5.

To replace the Harness you will have to replace to complete top

due to the harness being foamed into the top at the time of

manufacture.

6.

You will have to pull the Control Panel and disconnect the Food

Probe Harness in the back ductwork.

7.

Remove the Stainless Steel Work top.

8.

Remove the top that contains the Food Probe Harness and install

the new one in its place.

9.

Reinstall all of the parts to normal working positions.

RBC50 SMART CHILL

1.

On the RBC50 it has been found that the ”Defrost Time” setting

CONTROL

can possibly be set to 40 min.

2.

Should this be true of the unit you are working on, you will need to

go into program “85” and navigate thru the settings to press the

“Reset” button in the first screen and then go thru until you get to

the “Security” screen.

3.

Press the “Reset” button again.

4.

All settings will default to original settings (RBC100). Use the

button to the right of “Machine Size” to change from the 100 to

the 50 and then press “Exit”.

5.

In the next screen press the “Yes” button t

o save your changes.

6.

Proceed to the Main Menu.

7.

Go back into the “85” program and press the rest button for the

second time. Then go to the screen that shows the defrost time.

8.

Use the down arrow to change the defrost button to 15 min.

9.

Press the “Back button to go back to the first screen in program

“85” to enter the correct serial number this allows usage of the

Blast Chill Communication software.