4

IV. SMART CHILL CONTROL

IV.a

–

SEQUENCE OF OPERATION:

a.1

–

Control Revision Numbers

There are multiple versions of the Smart Chill Control

V1.08 - V2.11. Largely troubleshooting on all versions

will be the same.

a.2

–

System Idle:

The Smart Chill control is meant to maintain a median

operating temperature of 37F - 40F when in idle (no

active batches). During this time only

the

“Maintenance” or holding system is active

with the

exception of the RBC200 which runs the Blast system

ever other cycle. Anytime the display shows to be at

the “Main Menu” the system is in idle.

a.3

–

Chill Cycle:

When a standard chill cycle or batch is started the unit

will maintain a median temperature of 10F-14F until all

product is chilled to 37F, if using food probes, or until

preset time is complete. During this time both the

“Maintenance” and “Blast” systems will be active.

a.4

–

Holding:

Once all product reach 37F or below, or the preset time

is completed, the unit will begin what is called a

“Holding” mode. During “Holding”

the unit will again

maintain 37F - 40F but both systems continue to

operate because of the known product load. Once the

operator removes the product and acknowledges the

removal of product via the control the system returns

to idle or the “Main Menu”.

a.5

–

Defrost:

Models RBC100, RBC200, and RBC200RT have electric

defrost. Models RBC50 have hot gas defrost. On all

units defrost is scheduled to occur every 3 hrs and

terminates at a 50F coil temperature. RBC100, RBC200

and RBC200RT have a max defrost duration 40 minutes

while the RBC50 has a max defrost duration of 15

minutes. Once a defrost is initiated it cannot be

overridden or terminated by any method other than

meeting control parameters (time or temperature). The

Smart Chill control WILL NOT initiate a defrost cycle

during a chill cycle. Rather it will flash DEF REQD in

the top left portion of the display screen when a defrost

is required during a chill cycle. Once the chill cycle

completes the unit will then initiate a defrost. The

Smart Chill control WILL initiate a defrost during a Hold

mode.

For more information regarding additional operating

modes and conditions please reference the Owner’s

Manual.

IV.b

–

Manual Defrost:

To initiate a manual defrost the system must be in

idle and at the main menu. Once a defrost is

initiated it cannot be overridden and terminated by

IV.b

–

MANUAL DEFROST (CONT):

any method other than meeting control parameters

(time or temperature).

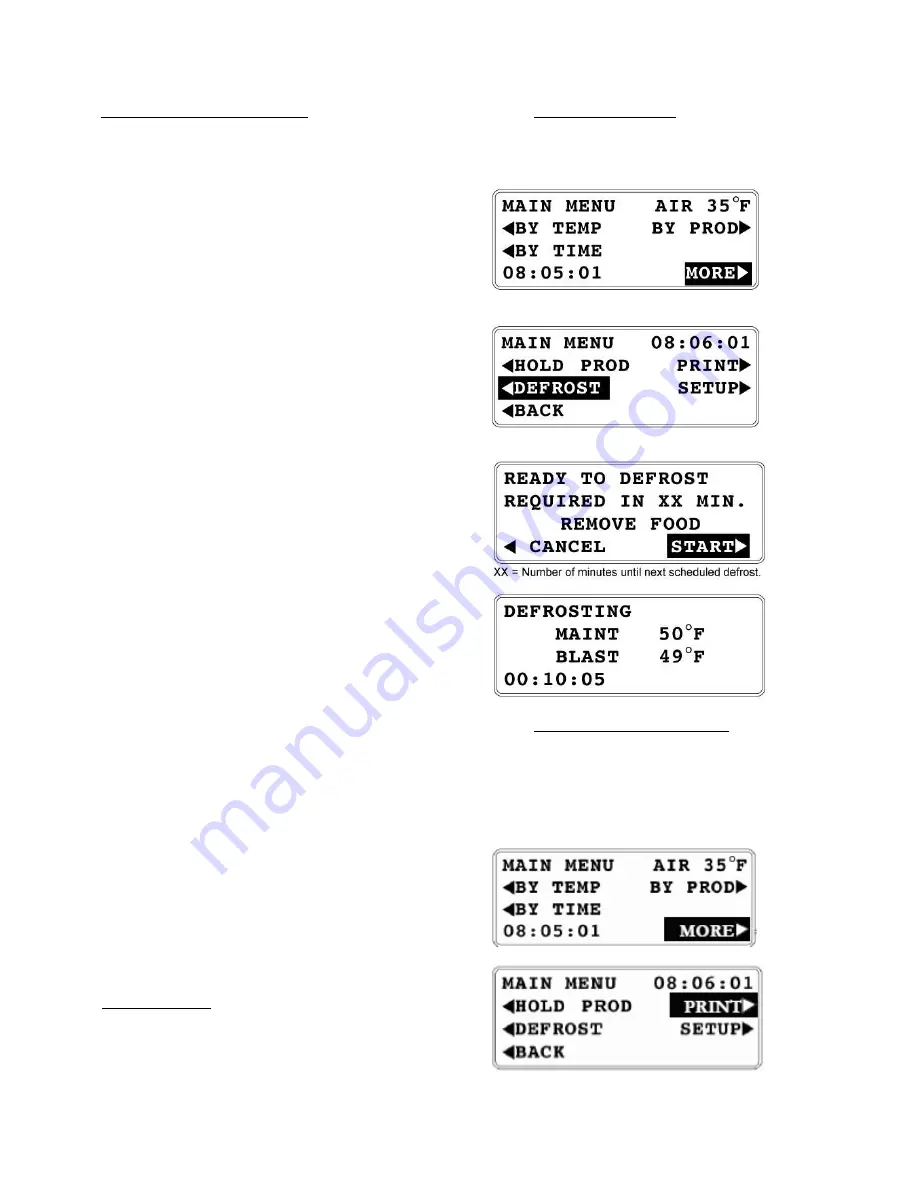

1. From the “MAIN MENU” select “MORE”

2

. Select “DEFROST”

3

. Select “START” th

e unit should now be in a defrost.

IV.c

–

PRINTING CONTROL DATA:

c.1

–

Cycle/Batch Data:

All batches run “BY TEMP” or using “EASY START”

will be stored in memory. At any time we can access

this data and reprint Cycle/Batch data using the

following instructions.

1. From the “MAIN MENU” select “MORE””

2

. Select “Print”

(Continued on next page)