-2-

II. RECEIPT INSPECTION

All Traulsen products are factory tested for performance

and are free from defects when shipped. The utmost care

has been taken in crating this product to protect against

damage in transit.

You should carefully inspect your unit for damage during

delivery. If damage is detected, you should save all the

crating materials and make note on the carrier’s Bill Of

Lading describing the damage. A freight claim should be

filed immediately. If damage is subsequently noted during

or immediately after installation, contact our customer care

team to file a freight claim. There is a fifteen (15) day limit

to file freight damage with the carrier. Under no condition

may a damaged unit be returned to Traulsen without first

obtaining written permission (return authorization).

You

may contact Hobart/Traulsen customer care at 800-

333-7447 to request a return or file a claim.

III. a-LOCATION:

Select a proper location for your unit, away from extreme

heat or cold. Allow enough clearance between the unit

and the side wall in order to make use of the door stay

open feature at 120

0

(self-closing feature operates up to

90

0

). The door must be able to open a minimum of 90

0

in

order to make use of the maximum clear door width. Al-

low a minimum of 12 inches (high) above the cabinet for

proper air circulation.

III. b-PACKAGING:

Your Traulsen unit is shipped from the factory bolted to a

sturdy wooden pallet in stretch wrapped material.

Most exterior stainless steel surfaces have a protective

vinyl covering to prevent scratching during manufactur-

ing, shipping and installation. After the unit is installed in

place of application peel, remove and discard the covering

from all surfaces.

To remove the wooden pallet, first if at all possible, we

suggest that the cabinet remain bolted to the pallet dur-

ing all transportation to the point of final installation. The

bolts can then be removed with a 1/2” socket wrench.

Avoid laying the unit on its front, side or back for removal

of the pallet.

NOTE:

Traulsen does not recommend laying the unit on

its front, side or back. If you must, please allow the unit to

remain in an upright position for 24 hours before plugging it

in so that the compressor oils and refrigerant may settle.

III. INSTALLATION

III. INSTALLATION (cont’d)

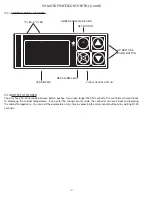

III. c-INSTALLING/ADJUSTING LEGS OR

CASTERS:

To install legs or casters, slide leg or caster into the caster chan-

nel from the side of the unit without the refrigeration system.

To adjust the legs or casters, loosen the two bolts and move

leg or caster to desired location, spacing between leg or caster

not to exceed 39 inches. Leg or caster on each end of the unit

can not exceed 8 inches from the end of the cabinet.

NOTE:

Traulsen recommends to position legs or casters under

the mullion when possible.

III. d-CORD & PLUG:

All self-contained models are shipped standard with a NEMA

5-15P plug and 9 foot cord . Select only a dedicated electrical

outlet for power source.

Do not cut or remove the round grounding

prong from the plug. Do not use an extension cord.

III. e-POWER SUPPLY:

The supply voltage should be checked prior to connection to

be certain that proper voltage for the cabinet wiring is available

(refer to the serial tag to determine correct unit voltage, see

page 1). Make connections in accordance with local electrical

codes. Use qualified electricians.

Use of a separate, dedicated circuit is required. Size wiring

to handle indicated load and provide necessary over current

protector in circuit (see amperage requirements on the unit’s

serial tag).

BOLT

CASTER CHANNEL

CASTER PLATE

Summary of Contents for TU048QC

Page 22: ...NOTES ...

Page 23: ...NOTES ...