Appendix 4 - Wiring Diagrams, Electrical Spec's

Page 47

Printed 3/18/98

Travis Industries Pellet Stove Troubleshooting Guide (

1994)

A

UGER

T

IMING

B

LOCK

OFF

ON

10

5

7.5

2.5

1

8

9

1

4

2

5

3

TYPE

TGKAD1010/010AD1S2

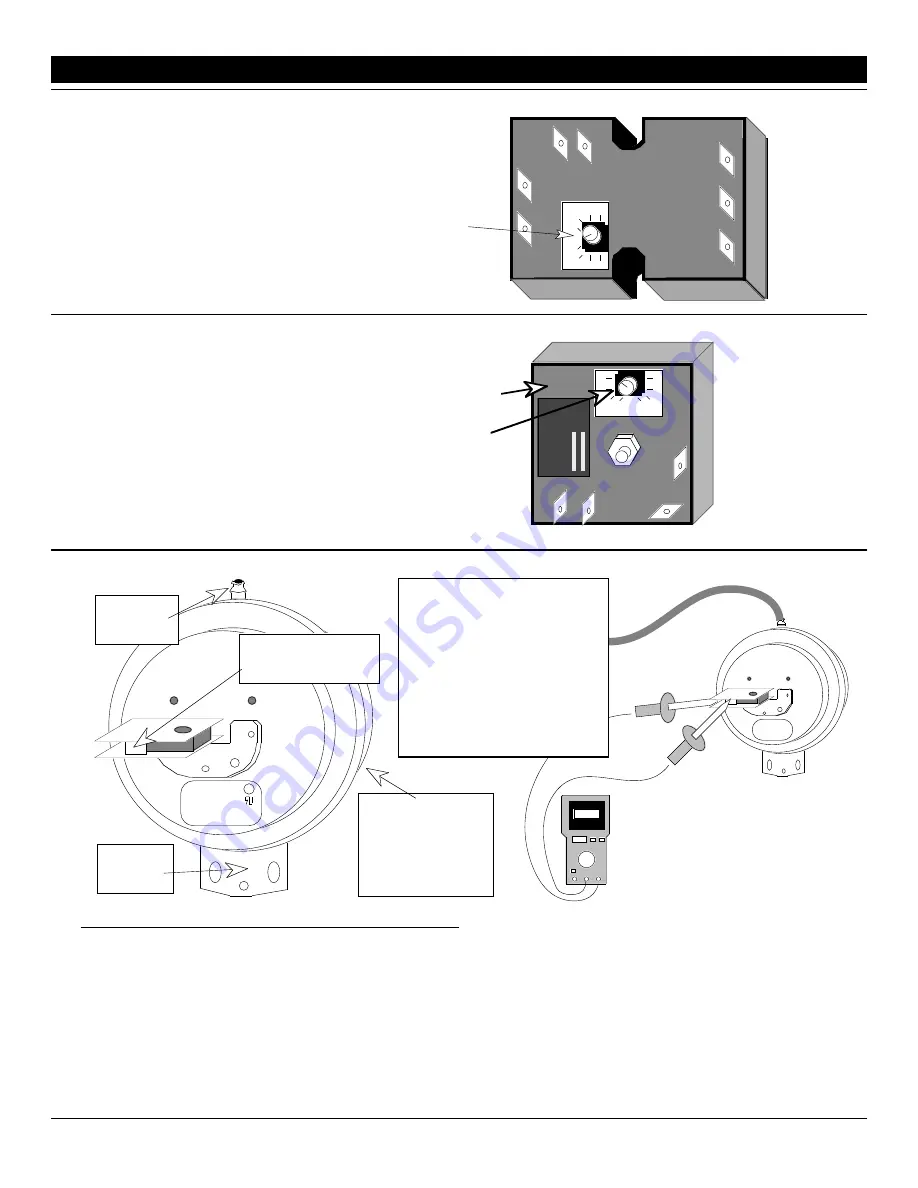

The auger timing block has a pot to adjust the off

time. On HIGH the auger should be on for 3

seconds, and off for a split second. On LOW the

auger should be on for 3 seconds, and off for

approximately 10 seconds.

S

TARTUP

T

IMING

B

LOCK

ZETTLER

AZZ8-1CH-48DE

TYPE TGLB1900A2S

1

2

3

5

15

7.5

10

5

1

The Start-Up timing block provides power

to the exhaust, igniter and auger circuits

for the first 15 minutes. If the start-up

time is too short, make sure this pot is

turned all the way clockwise (15 minutes)

START-UP TIMING BLOCK

F

LOW

S

WITCH

TRIDELTA IND. INC.

MENTOR, OH 44060

FS6669-1300

011617 / 4592

MOUNT (MONER) DIAPHRAGM

(MEMBRANE) VERTICAL

Nipple for

Tubing

Electrical

Connections (Two)

Mounting

Bracket

Adjustment

Screw (On Back

side in the center

- must be sealed

after adjusting)

To check this component,

perform a continuity check

between the two electrical

connections. With the flow

switch idle, there should be no

continuity. While providing

suction on the tubing you should

have continuity. The flow switch

should be replaced if it does not

react in this manner.

Altitude Considerations for the Flow Switch

The flow switch monitors the pressure in the exhaust system. The pressure in the firebox on our pellet heaters

is approximately .9" to 1" (water column static pressure) hot at sea level, .7" to .8" hot at 5,000 to 9,000 feet,

1.3" to 1.5" cold at sea level, and 1" to 1.2" cold at 5,000 to 9,000 feet. The flow switch shuts off the auger

circuit when the pressure drops below .5" (approximate). When the stove is hot at high altitudes the flow

switch is closest to switching off. Small blockages or long pellet vent runs may trigger the flow switch in this

situation. If the flow switch shuts off the auger regularly, it can be adjusted. There is an adjustment screw on

the back of the flow switch (standard screw or allen head screw - re-seal with silicone after adjusting). Adjust

this screw inwards (clockwise) to make the flow switch less sensitive. After making any adjustment make

sure the flow switch disables the auger motor when the flow switch tube is disconnected.

Summary of Contents for 400 PI

Page 46: ......