Page 48

REPLACEMENT PARTS AND REMOVAL INSTRUCTIONS

(Continued)

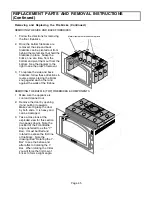

Removing and Replacing the Secondary Air Tubes

The secondary air tubes are two tubes with holes that run along the top of the firebox. Over time they may

wear and become ineffective. The secondary air tubes should be replaced if they crack or show severe

deterioration, because they supply air into the firebox that allows for a more efficient fire. There are two

secondary air tubes, one is in the front of the firebox and the other is in back. These parts are available

from your dealer.

To remove either

secondary air tube, first

remove the two pins

located on the right side

of the firebox that hold

the tube in place.

These pins are

removed by using a

screwdriver or needle-

nose pliers to pry them

out of their holes. The

pins are held in place

by flanges on the pins

that expand once they

are pushed into the

hole. Therefore, you

may have to pry with

some amount of force

when trying to remove

them.

Secondary Air Tube

Pins that hold Secondary

Air Tube and Collar in Place

Collar

Air Induction

System (Welded

to side of Firebox)

Slide collar to the

left after removing

both of the pins.

Short Tube that is

welded to the Air

Induction System

One pin holds the secondary air tube to a collar while the other pin holds the collar to a short tube welded

to the air induction system. Once both pins are removed, the collar can be slid to the left and the

secondary air tube and collar can be pulled down and away from the left side. To replace the secondary

air tube, place the collar on the secondary air tube, insert the secondary air tube into the hole on the left

side of the firebox, and slide the collar over to the right so it slides over the short tube that is welded to the

air induction system on the right side. Then line up the secondary air tube and collar so the holes for the

pins line up and insert both new pins that are included with the replacement air tube kit.