Operation

25

© Travis Industries

4/11/22- 1566

AGP Stove

TSTAT (Thermostat) Mode

TSTAT mode allows you to use a thermostat to control room temperature. The stove automatically

turns on when the temperature drops below the thermostat setting and turns off (or too low) once the

thermostat setting is met.

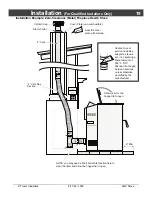

To Start the Stove in TSTAT Mode

Press the TSTAT button on the

control panel. If there is a call for

heat from the thermostat, the

stove will enter the start-up

sequence for approximately 22

minutes.

To Adjust the Heat Output

Use the HEAT knob on the control panel to adjust the heat output.

NOTE:

Depending upon which TSTAT Program you are in (1, 2, or 3), the heat output may vary once the target

temperature is reached. For details see “Changing the TSTAT Program” on the following page.

TIP:

If you find that the stove turns on and off repeatedly, you may wish to turn the heat output to a lower

setting, which will provide a more consistent heat output over time, and eliminate the need for the

thermostat to repeatedly turn the stove off.

To Shut Down

Press the STOP or TSTAT

button on the control panel

or

turn the thermostat down

below the room temperature.

The stove will begin the shut-

down process, which takes

approximately 45 minutes.

TSTAT

STOP

HEAT

FAN

AUTO FAN

LOW

HIGH

www.travisproducts.com

GLASS AND SURFACES OF UNIT

CAN GET HOT ENOUGH

TO CAUSE SEVERE BURNS.

KEEP CHILDREN AND PETS AWAY.

WARNING

START

LOW

HIGH

TSTAT

STOP

HEAT

FAN

AUTO FAN

LOW

HIGH

www.travisproducts.com

GLASS AND SURFACES OF UNIT

CAN GET HOT ENOUGH

TO CAUSE SEVERE BURNS.

KEEP CHILDREN AND PETS AWAY.

WARNING

START

LOW

HIGH